A pressing method for pasting protective film of automobile door

A technology for automobile doors and protective films, which is applied in the field of pressing devices, can solve the problems of uneven force on the flanging and pressing of protective films, space limitations, and the influence of the quality of the upper door protective film pasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

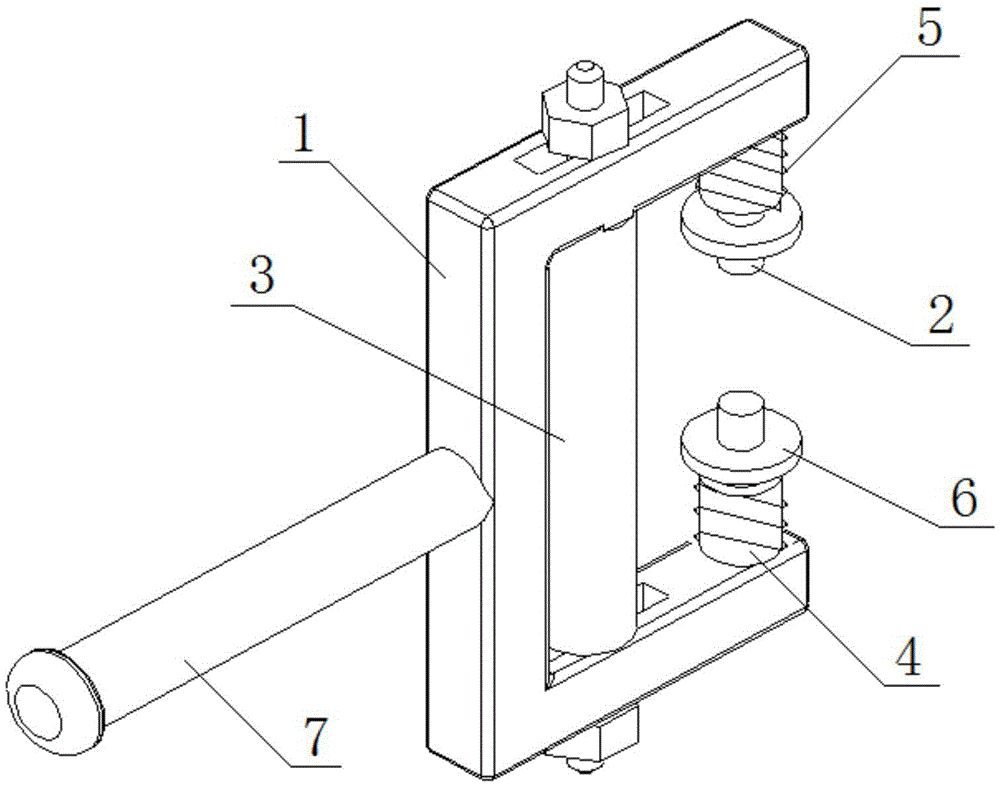

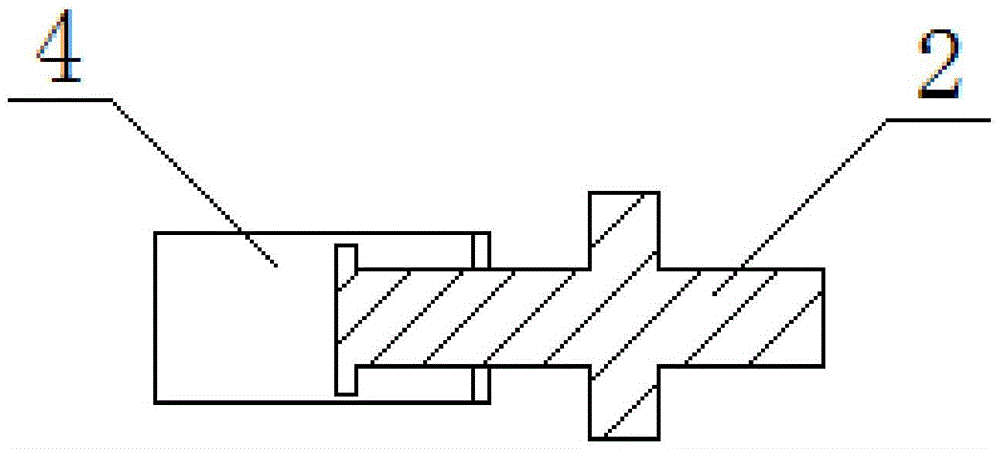

[0016] figure 1 It is a structural schematic diagram of the pressing method for pasting the protective film of the automobile door of the present invention, figure 2 It is a schematic diagram of the structure of the fixing card and the guide post, which is represented by figure 1 with figure 2 It can be seen from the combination that the pressing method for pasting the protective film of automobile door includes:

[0017] 1) After the protective film is flanged and pasted, adjust the position of the corresponding parts of the pressing device. The pressing device includes a U-shaped pressing device body 1. The pressing device body 1 is located inside the two sides The tops of the two sides are respectively provided with fixing cards 2 for fixing the door. The inner sides of the two sides of the pressing device body 1 and the bottoms of the two sides are provided with rollers 3. The two ends are respectively installed on the two sides of the U-shaped pressing device body 1 by bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com