A method for ultrasonic positioning and wall breaking of traditional Chinese medicinal materials

A technology of ultrasound and Chinese herbal medicines, which is applied in the field of ultrasonic positioning and broken walls of Chinese herbal medicines, which can solve the problems of rough taste, easy loss of nutrients, incomplete wall breaking, etc., and achieve the effect of fine taste and no loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Cordyceps sinensis wall breaking method

[0025] Cordyceps sinensis ultrasonic positioning broken wall method, according to the following steps:

[0026] a. In the X-ray metal detector, screen the whole Cordyceps sinensis that does not contain metal components, wash and dry it for later use;

[0027] b. In a 100,000-class clean GMP space, put the Cordyceps sinensis treated in step a into a centrifuge tube, and fix it in a non-contact ultrasonic positioning wall breaking device;

[0028] c. Set the ultrasonic time to 25 minutes, and the ultrasonic program is ultrasonic for 2 seconds, with an interval of 2 seconds, repeat the above program, and control the temperature in the non-contact ultrasonic positioning wall breaker within 60 degrees;

[0029] d. Finish breaking the wall and put it into the packaging machine for packaging.

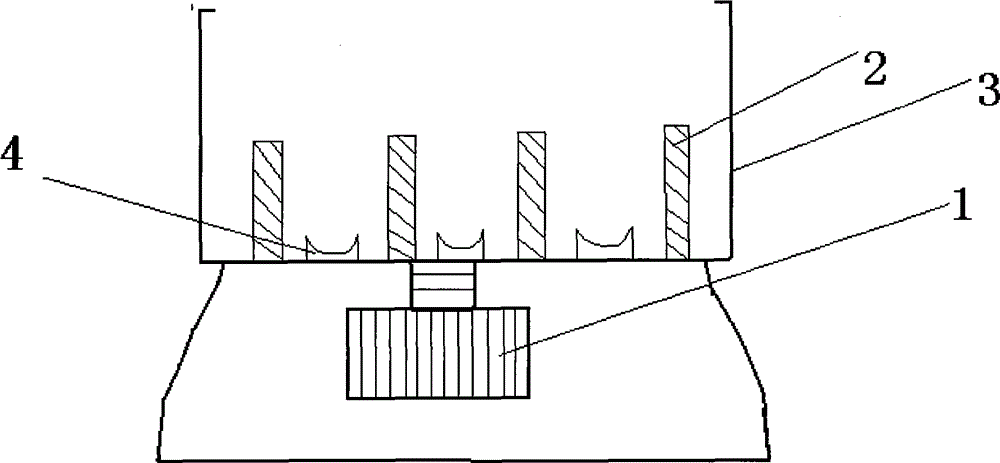

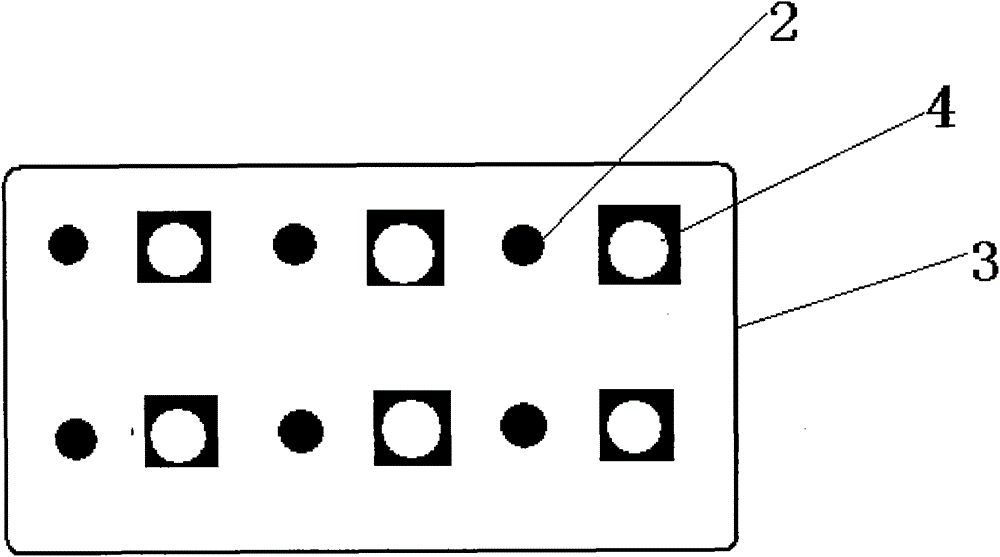

[0030] Such as Figure 1-2 As shown, the above-mentioned non-contact ultrasonic positioning wall breaking instrument is compose...

Embodiment 2

[0031] Embodiment 2 dendrobium broken wall method

[0032] Dendrobium candidum ultrasonic positioning broken wall method, according to the following steps:

[0033] a, select the stem of the dendrobium that is fresh without insect bites, clean and dry for subsequent use;

[0034] b. In a 100,000-class clean GMP space, put the dendrobium treated in step a into a centrifuge tube, and fix it in a non-contact ultrasonic positioning wall breaking device;

[0035] c. Set the ultrasonic time to 20 minutes, and the ultrasonic program is ultrasonic for 3 seconds, with an interval of 2 seconds, and repeat the above program to control the temperature in the non-contact ultrasonic positioning wall breaker within 60 degrees;

[0036] d. Finish breaking the wall and put it into the packaging machine for packaging.

[0037] Such as Figure 1-2 As shown, the above-mentioned non-contact ultrasonic positioning wall breaking instrument is composed of an ultrasonic generator 1, a transducer 2,...

Embodiment 3

[0038] Embodiment 3 yeast wall breaking method

[0039] The method of ultrasonic positioning and wall breaking of yeast is carried out according to the following steps:

[0040] a. Cultivate yeast cells in yeast culture solution, collect, centrifuge, and dry for later use;

[0041] b. In a 100,000-class clean GMP space, put the yeast treated in step a into a centrifuge tube and fix it in a non-contact ultrasonic positioning wall breaking device;

[0042] c. Set the ultrasonic time to 30 minutes, and the ultrasonic program is ultrasonic for 3 seconds, with an interval of 3 seconds, repeat the above procedure, and control the temperature in the non-contact ultrasonic positioning wall breaker within 60 degrees;

[0043] d. Finish breaking the wall and put it into the packaging machine for packaging.

[0044] Such as Figure 1-2 As shown, the above-mentioned non-contact ultrasonic positioning wall breaking instrument is composed of an ultrasonic generator 1, a transducer 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com