Wind power bus connector

A technology for wind power busbars and connectors, which is applied to the installation of busbars, electrical components, cables, etc., can solve the problems affecting the reliable operation of equipment, easy deformation or damage of wind power busbars, and inability to adapt to wind power generation equipment, etc. Easy installation, simple structure, and the effect of avoiding rigid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

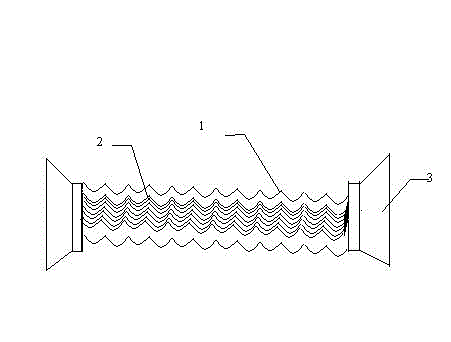

[0009] As shown in the figure, a new type of wind power busbar connector includes two sections of rubber tube 1 to be connected and a tubular flexible conductor 2. The tubular flexible conductor 2 is arranged in the rubber tube 1, and the rubber tube 1 is Wavy distribution.

[0010] The two ends of the rubber tube 1 are provided with metal sleeves 3, and the metal sleeves are convenient to be fixedly connected to the busbars of the corresponding busbars as a whole, and the metal sleeves are in a trumpet shape. When in use, the tube-shaped flexible conductor 2 is passed through the rubber tube 1, and the metal sleeve 3 on the rubber tube 1 is connected to the bus duct by welding.

[0011] The invention is simple in structure, convenient to manufacture and install, and the flexible connection structure of the soft connection enables the wind power bus to avoid the rigid damage to the power bus components during the swing of the wind power tower.

[0012] The description and applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com