Height-adjustable photovoltaic component bracket structure

A photovoltaic module and support structure technology, applied in the field of construction engineering, can solve the problems of many consumables and slow construction progress, and achieve the effects of improving safety, convenient height adjustment, and saving construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

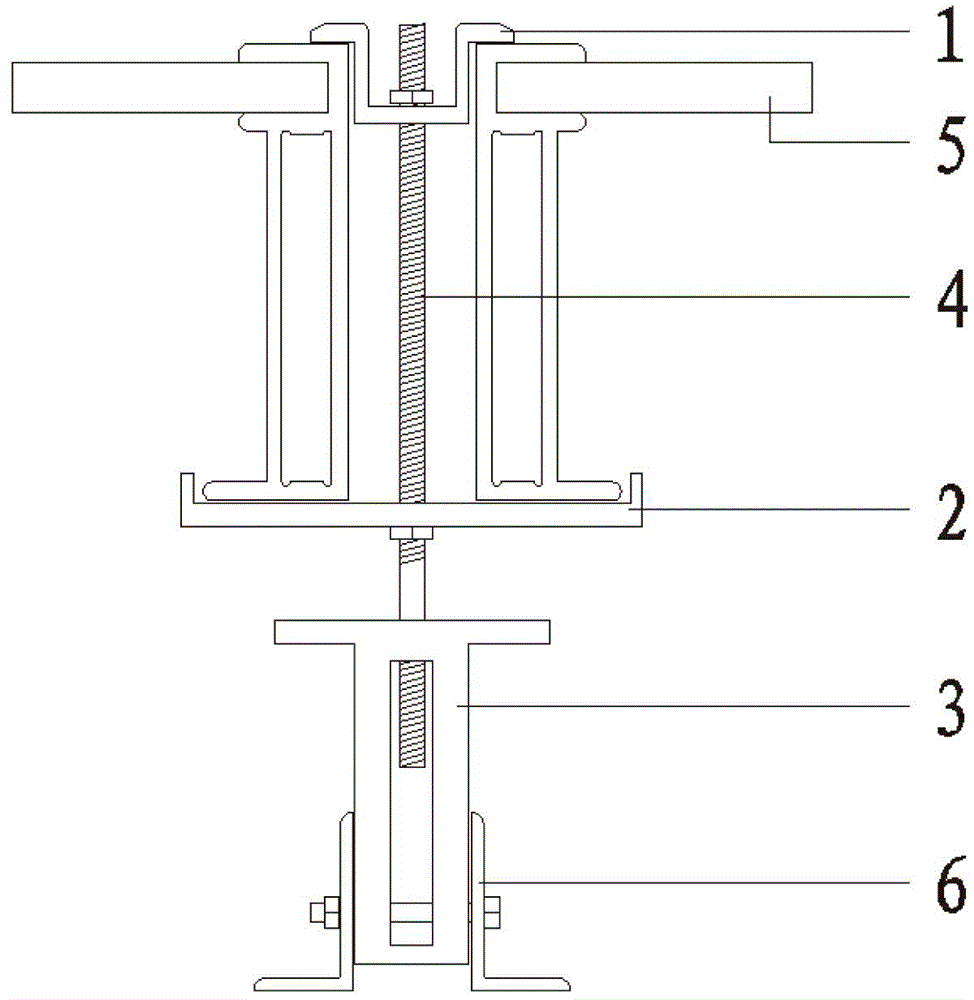

[0013] Structural schematic diagram of the present invention is as figure 1 As shown, Figure 2 is a schematic diagram of the assembly structure in use state. Depend on figure 1 and figure 2 It can be seen that a height-adjustable photovoltaic module support structure includes a photovoltaic module 5 and a support 3, and is characterized in that: the U-shaped clip 1, the photovoltaic module 5, the supporting plate 2 and the support 3 Arranged in sequence from bottom to bottom, and fixed by thread connection with double-headed long bolts 4; there are multiple photovoltaic modules 5, which are symmetrically arranged on both sides of double-ended long bolts 4, and the upper surface of the photovoltaic module 5 is connected with the U The lower surface of the outer flange of the U-shaped clip 1 is connected, the lower end of the photovoltaic module 5 is placed in the groove of the supporting plate 2, and the upper end of the double-headed long bolt 4 is at the bottom of the U-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com