Truck vibration energy recovery system

A vibration energy recovery and truck technology, applied in vehicle components, auxiliary drive devices, control devices, etc., can solve the problems of low energy recovery efficiency, poor reliability, and inability to achieve high-efficiency recovery of vibration energy, and improve the reliability of use. performance and energy recovery efficiency, avoid poor reliability, and avoid the effects of low energy recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

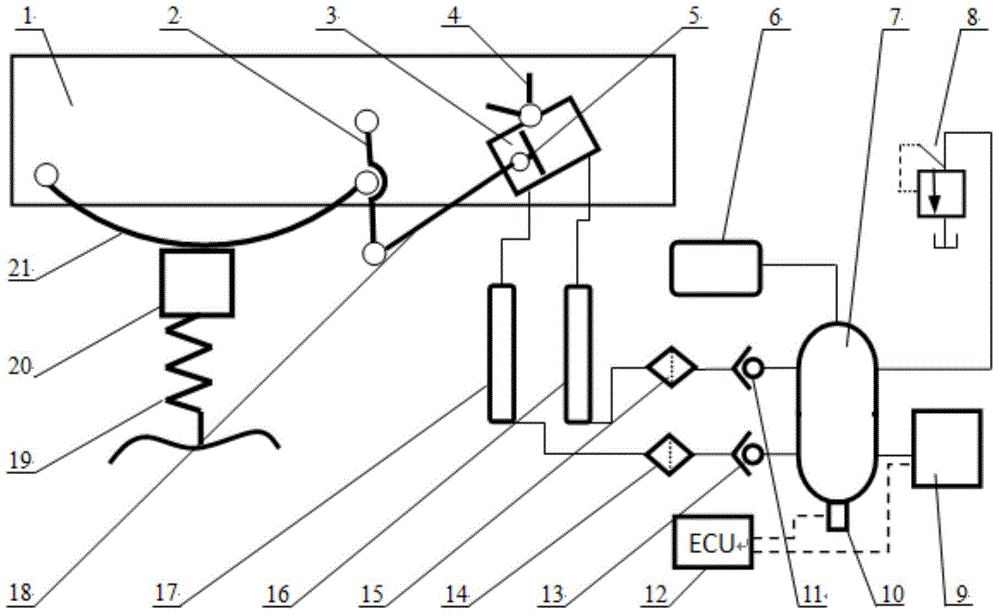

[0069] Next, a certain medium-sized truck produced by a certain automobile company is taken as a prototype vehicle to further illustrate the truck vibration energy recovery system of the present invention.

[0070] The overall structure of the truck vibration energy recovery system of the prototype vehicle is as described above. Wherein, the length of the gas storage tank 7 in the prototype vehicle is 500 mm, and the diameter is 250 mm.

[0071] In order to solve the problem of low energy recovery efficiency caused by high-frequency and small-amplitude vibration in the existing truck vibration energy recovery system, which is difficult to establish working pressure and less large-amplitude vibration, the present invention improves the original enlarged lifting lug of the leaf spring ( Length 110mm) is redesigned, according to the strength of the increased lifting lug material and the installation space, the length of the original increased lifting lug is doubled, and the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com