Constant-current static-pressure rolling composite guide rail and automatic centering technological worktable

An automatic centering and worktable technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of lack of key design theory and technology, worktable running swaying, low processing accuracy, etc., to overcome Unstable centering, uniform film floating, and small film fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

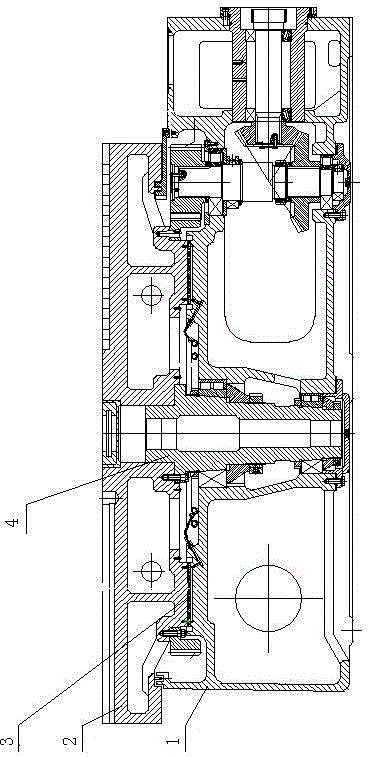

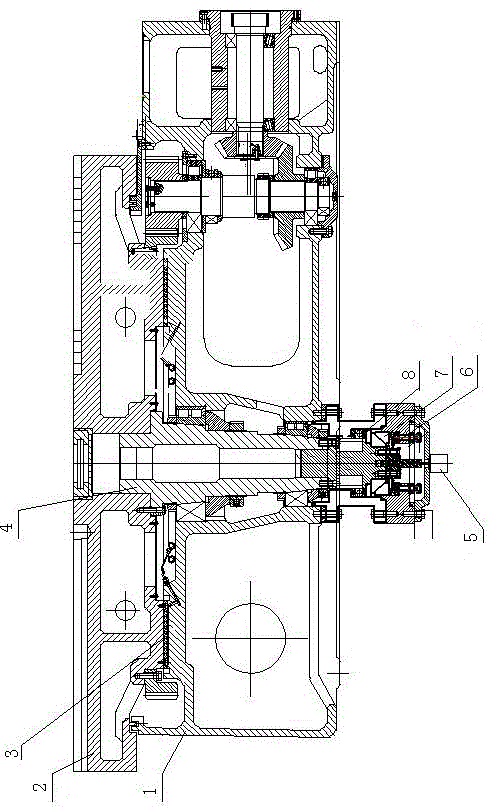

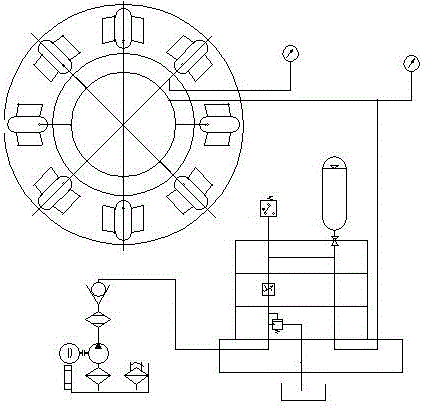

[0012] The structure of the constant-current static pressure rolling-sliding composite guide rail plus automatic centering technology workbench of the present invention is as follows: figure 2 As shown, there is a workbench 2 on the workbench base 1, the main shaft 4 is located in the middle of the workbench base 1 and the workbench 2, a guide rail plate 3 is provided between the workbench base 1 and the workbench 2, and a set of A one-way thrust ball bearing 8 and a set of thrust joint bearings 7 that automatically center the main shaft of the workbench. This structure still maintains the original main shaft structure. Two sets of double-row radial short cylindrical roller bearings (taper 1:12) are used for centering support in the radial direction. A set of one-way thrust ball bearings is added to the lower part of the main shaft. , and added a set of joint bearings 7 to automatically center the table spindle 1, and designed a disc spring 6 to adjust the preload of the guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com