Continuous activated carbon washing and drying device

An activated carbon and drying technology, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low dehydration efficiency, high residual phosphorus content, and limited practical application, so as to improve dehydration efficiency and reduce residual phosphorus The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

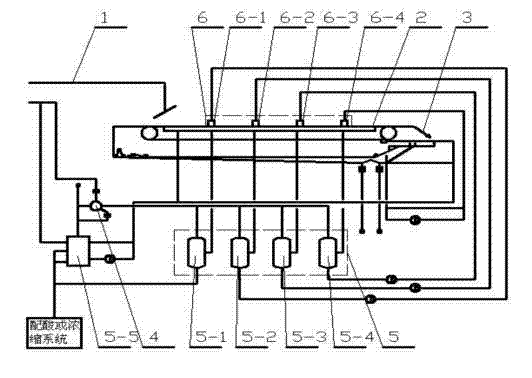

[0014] In the accompanying drawings, a device for continuous washing and drying of activated carbon, comprising a carbon slurry feeding device 1, a belt filter 2, a lower hopper 3, a vacuum suction filter device 4, a vacuum tank 5, a washing spray device 6 and Connecting pipes; based on the running direction of the belt filter 2, a carbon slurry feeding device 1 is provided on the front and top, and a lower hopper 3 is provided below the rear; the top of the belt filter 2 is provided with a washing Spray device 6, the bottom of described belt filter 2 is provided with vacuum tank 5; Described vacuum tank 5 is connected with belt filter 2 by pipeline; Described vacuum tank 5 is also connected with washing spray device 6 and vacuum suction. Filter device 4 is connected.

[0015] The belt filter 2 is provided with a rubber belt, a filter cloth, a vacuum box, a friction belt, etc., and the moving speed of the rubber belt is 1 to 20 m / min.

[0016] Said vacuum tank 5 comprises vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com