Friction-free constant force output gas floatation device

A constant force output, frictionless technology, applied in the direction of fluid pressure actuators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

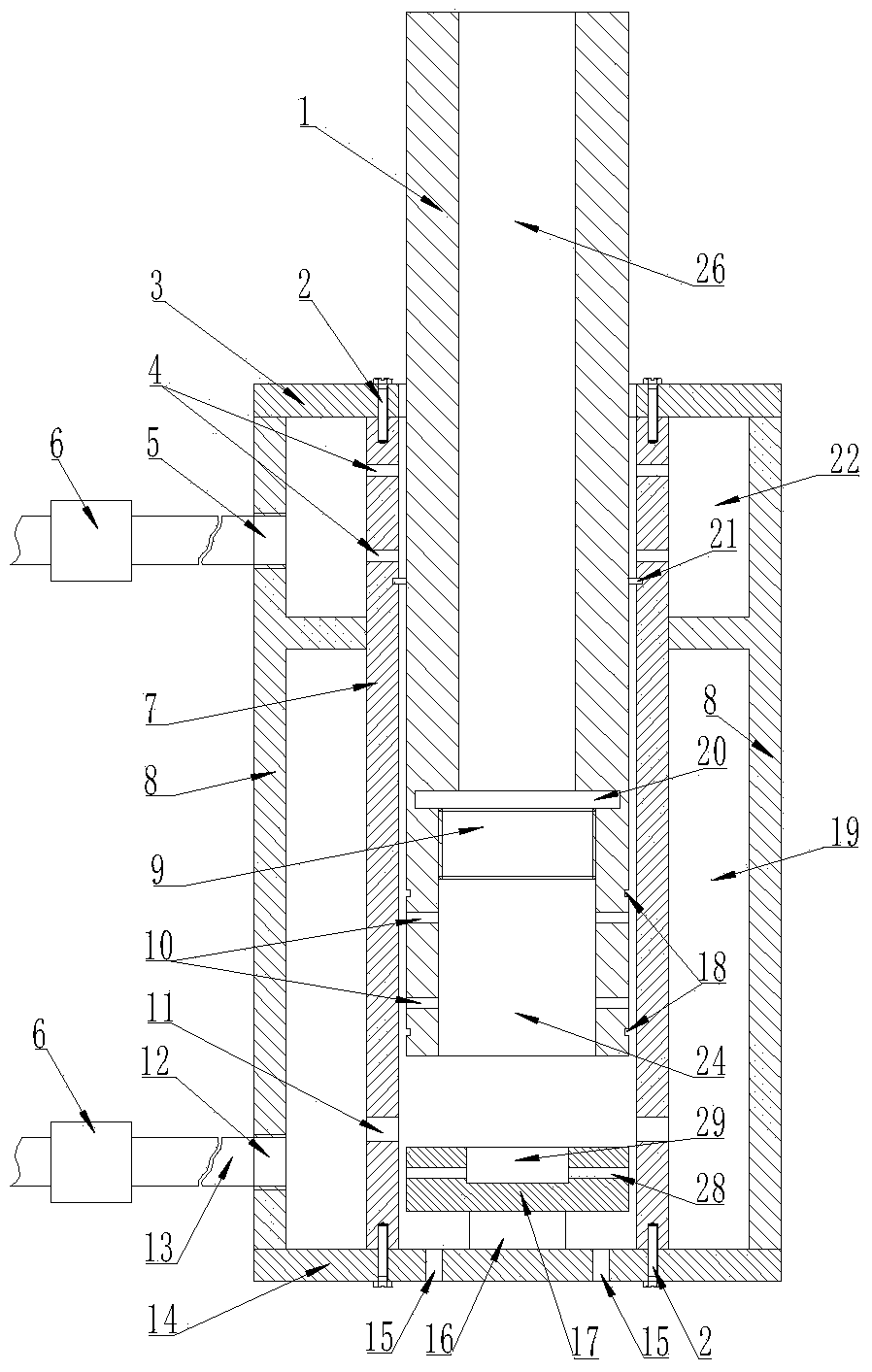

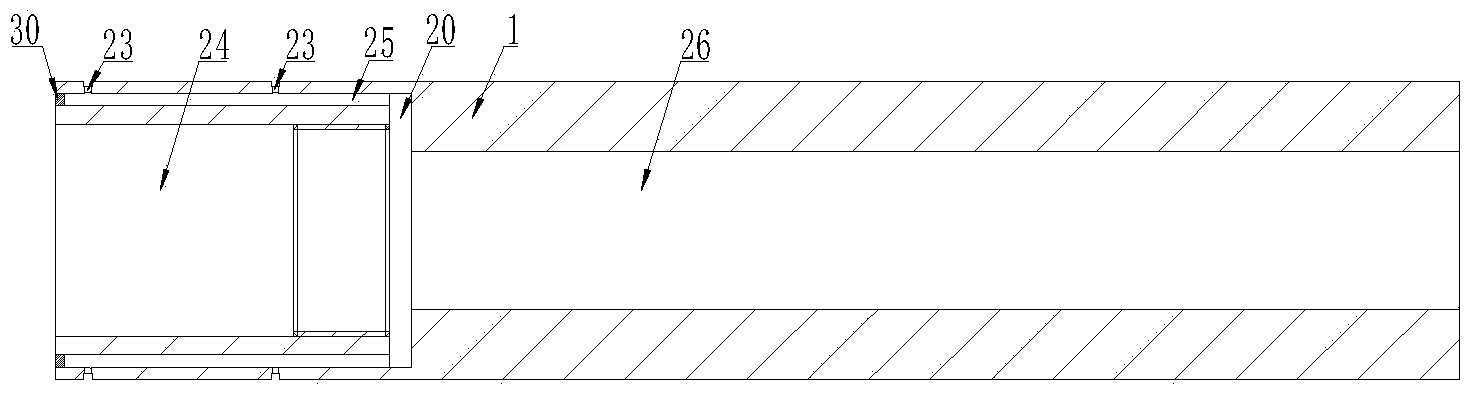

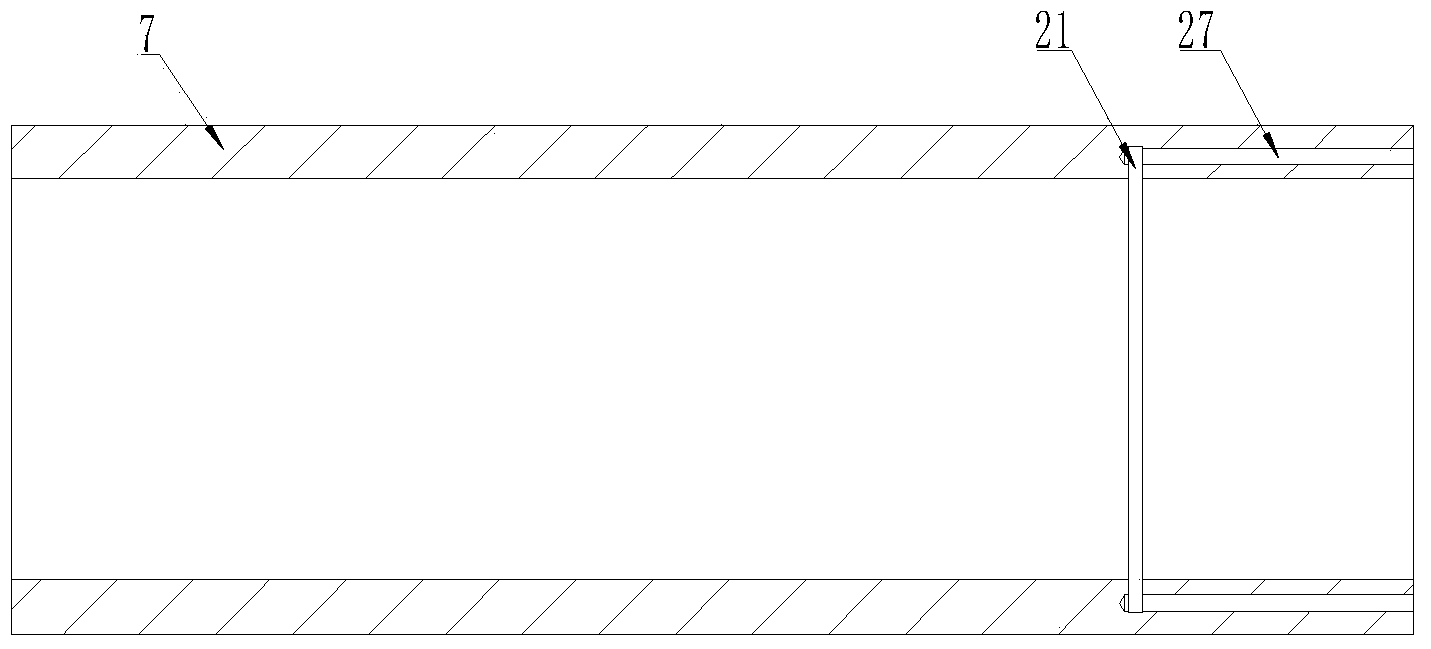

[0025] combine Figure 1 ~ Figure 3 , a frictionless constant force output air flotation device, including a long piston 1, a cylinder 7, an air storage sleeve 8, and an air pressure plate 17. The long piston 1 is set inside the cylinder 7 and there is a very small gap between it and the cylinder 7, the gas storage sleeve 8 is set outside the cylinder, the end cover 3 and the base 14 are set on the gas storage sleeve 8 and the cylinder 7 through the bolt 2 At both ends, the long piston 1 passes through the end cap 3 .

[0026] A first air storage chamber 19 and a second air storage chamber 22 are formed between the air storage sleeve 8 and the cylinder 7, which are independent of each other. The air storage sleeve 8 is provided with a first air inlet 12 and a second air inlet 5, the first air inlet 12 communicates with the first air storage chamber 19, and the second air inlet 5 communicates with the second air storage chamber 22 . The first air inlet 12 and the second air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com