Installation tool of gear drill tooth

A technology for installing tools and roller cone drills, which is applied to drill pipes, drill pipes, drilling equipment, etc., and can solve the problems of random irregular installation and low replacement efficiency of roller cones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

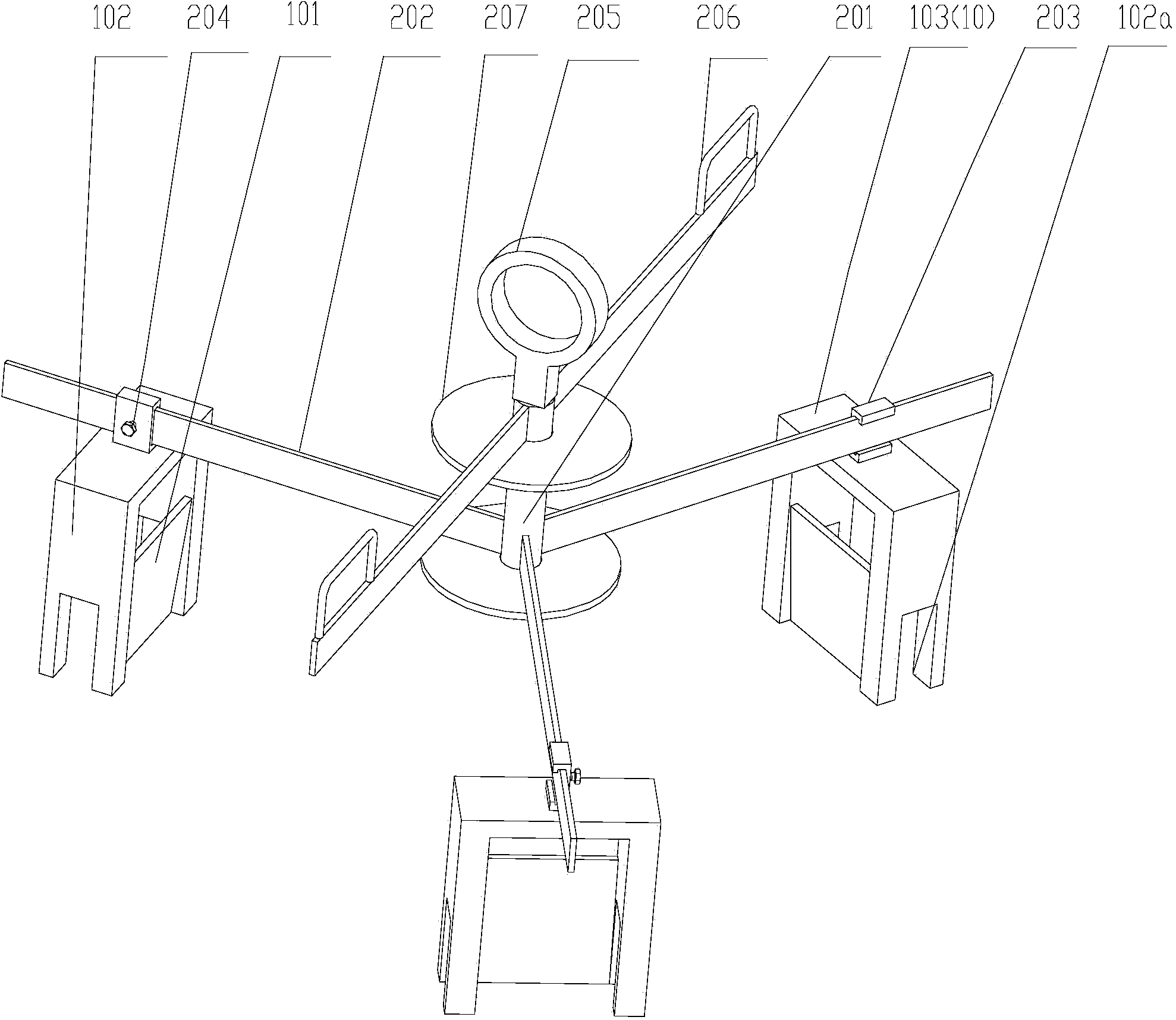

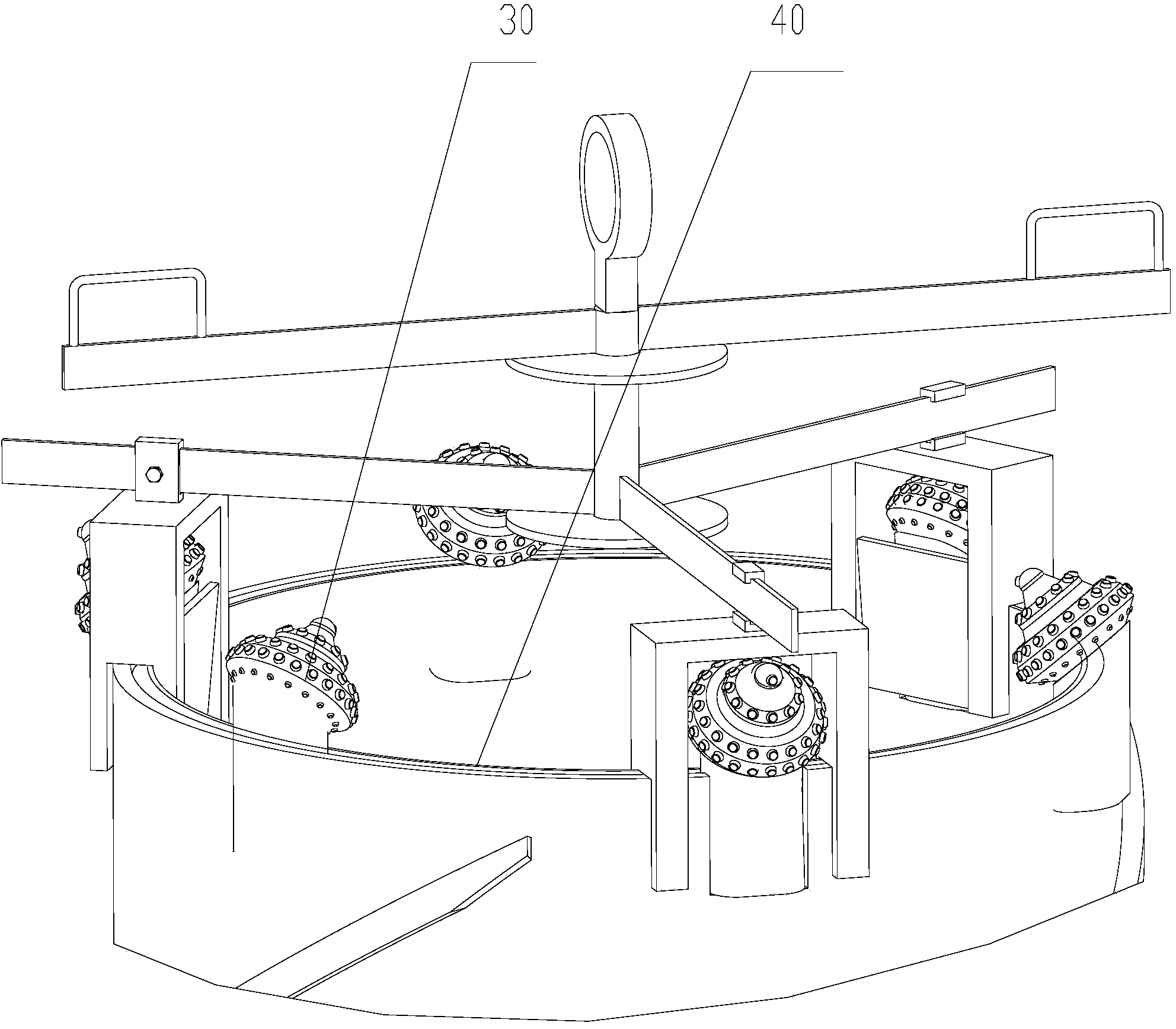

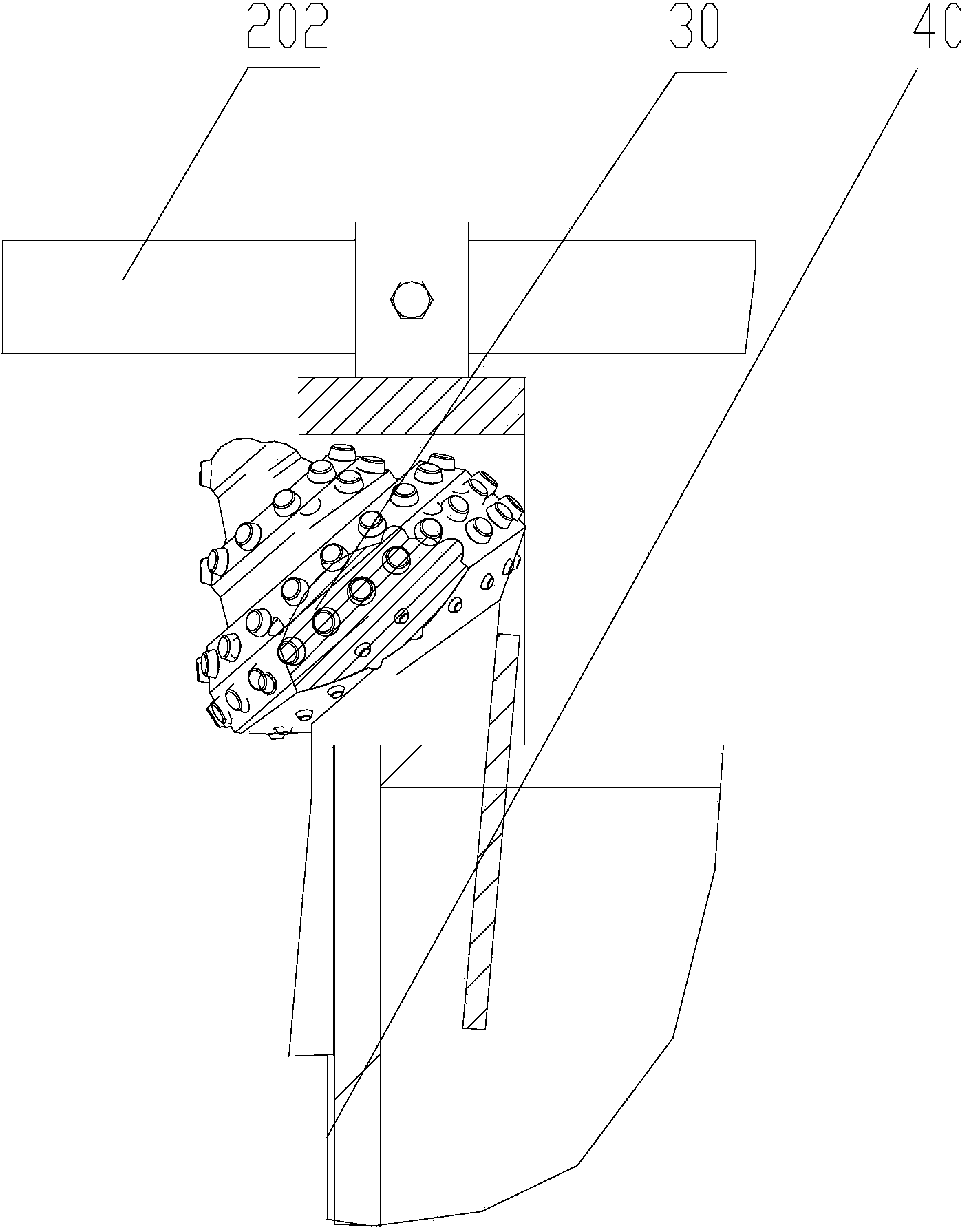

[0022] figure 1 The structural schematic diagram of the roller cone bit installation tool provided by the embodiment of the present invention, such as figure 1 As shown, the roller cone bit installation tool in this embodiment may include: a deck 10, the deck 10 includes a body and a backing plate 101, the inside of the body is a hollow structure for accommodating the roller cone bit, the body includes a side wall 102 and The bottom end of the top wall 103 and the side wall 102 of the main body is provided with a card slot 102a; the back board 101 is connected with the main body, and the inclination angle of the back board 101 is consistent with the installation angle of the roller cone bit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com