A kind of preparation method of chrysanthemum structure nanocomposite material

A nano-composite material, chrysanthemum technology, applied in chemical instruments and methods, textile industry wastewater treatment, titanium oxide/hydroxide and other directions, can solve the problems of high cost of functional materials, poor photocatalytic effect, etc., achieve low energy consumption, The preparation process is simple and feasible, and the visible light photocatalytic effect is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

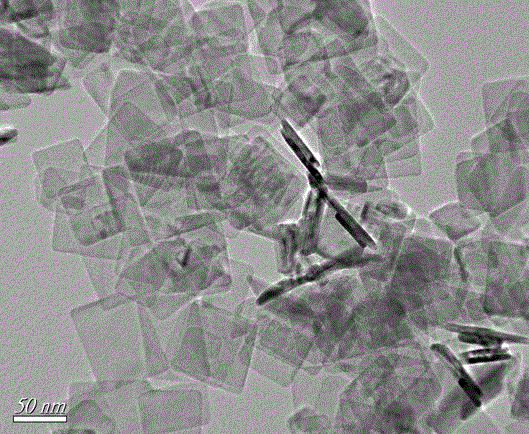

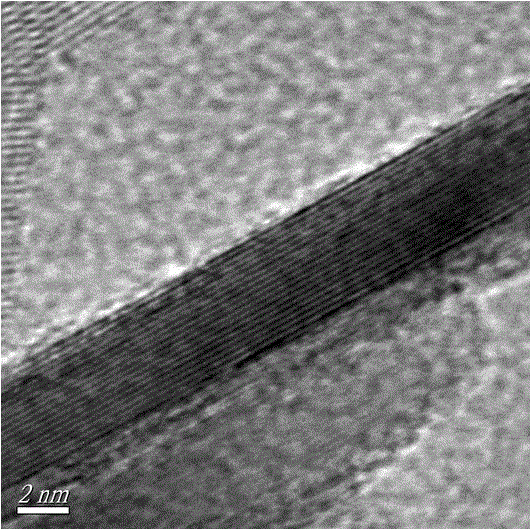

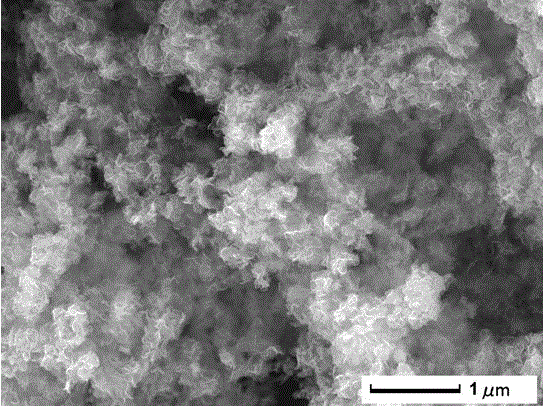

[0028] Add 15mg of titanium dioxide nanosheets into 60ml of deionized water, and ultrasonically disperse to obtain a titanium dioxide dispersion; under magnetic stirring conditions, add 90 mg of sodium molybdate and 180 mg of thioacetamide to the above titanium dioxide dispersion to obtain a mixed solution A; dropwise After the completion of the mixed solution, continue to stir for 30 minutes and transfer it to a polytetrafluoroethylene liner, and seal the liner into a stainless steel hydrothermal reaction kettle, and react at 200 °C for 20 hours. After the reaction, the reaction kettle is naturally cooled to room temperature. The obtained product was separated by centrifugation, washed with deionized water and absolute ethanol, and dried in vacuum.

Embodiment 2

[0030] Add 10 mg of titanium dioxide nanosheets into 60 ml of deionized water, and ultrasonically disperse to obtain a titanium dioxide dispersion; under magnetic stirring conditions, add 90 mg of sodium molybdate and 180 mg of thioacetamide to the above titanium dioxide dispersion to obtain a mixed solution A; dropwise After the completion of the mixed solution, continue to stir for 30 minutes and transfer it to a polytetrafluoroethylene liner, and seal the liner into a stainless steel hydrothermal reaction kettle, and react at 200 °C for 20 hours. After the reaction, the reaction kettle is naturally cooled to room temperature. The obtained product was separated by centrifugation, washed with deionized water and absolute ethanol, and dried in vacuum.

Embodiment 3

[0032] Add 15 mg of titanium dioxide nanosheets into 60 ml of deionized water, and ultrasonically disperse to obtain a titanium dioxide dispersion. Under magnetic stirring conditions, 90 mg of sodium molybdate and 180 mg of thioacetamide were added to the above titanium dioxide dispersion to obtain a mixed solution A. After the dropwise addition, the mixed solution continued to stir for 30 minutes, then transferred to a polytetrafluoroethylene liner, and sealed the liner into a stainless steel hydrothermal reaction kettle, and reacted at 180 °C for 24 hours. After the reaction, the reaction kettle was naturally cooled to room temperature , The resulting product was centrifuged and washed with deionized water and absolute ethanol, respectively, and dried in vacuum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com