Composite sandwich ventilation bra cup

A technology for breathable cups and sandwiches, which is applied in bras, clothing, applications, etc., can solve the problems that sandwich cups cannot achieve the effect of sticking and pulling, and cannot achieve the effect of modifying the breast shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

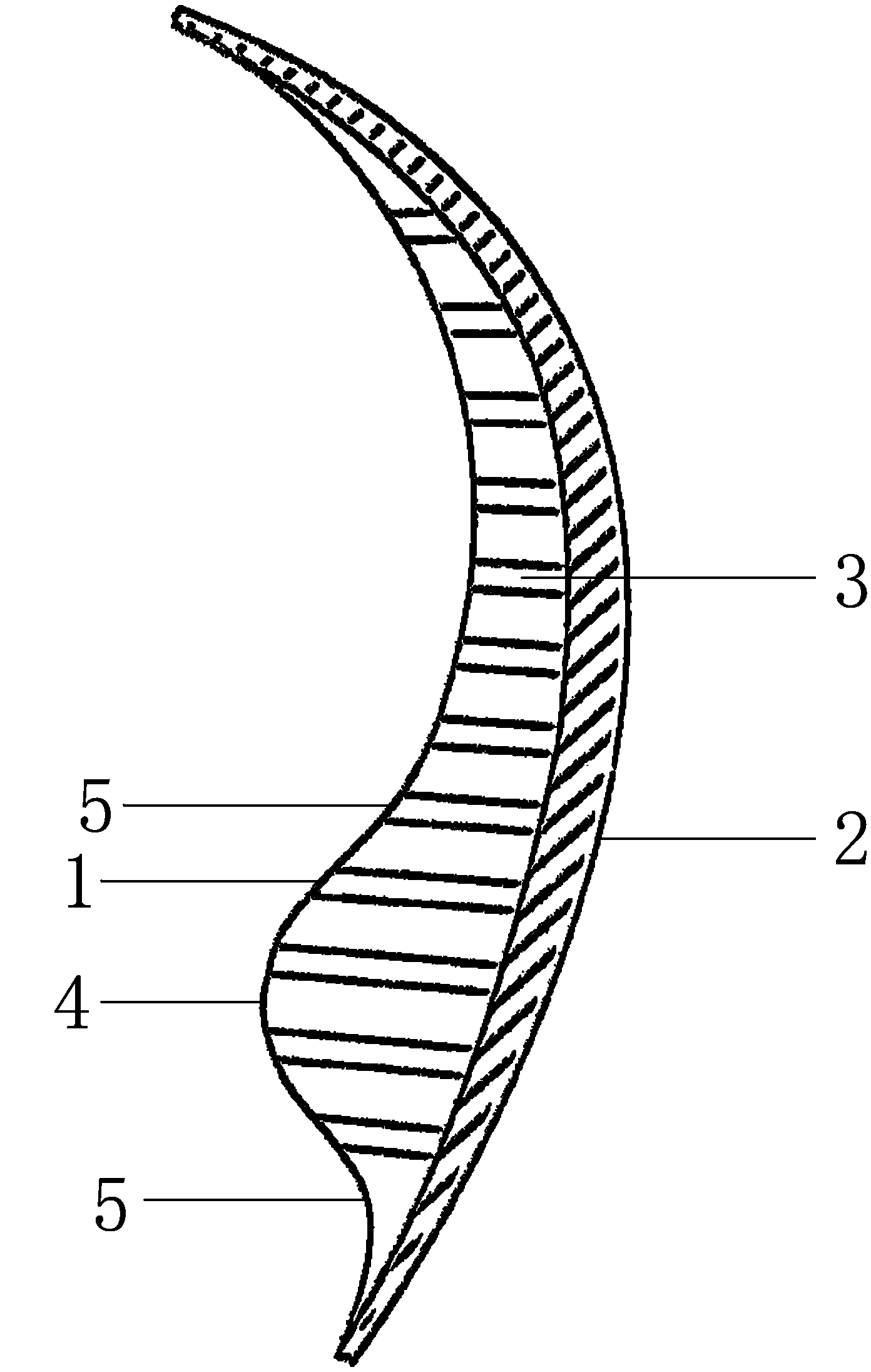

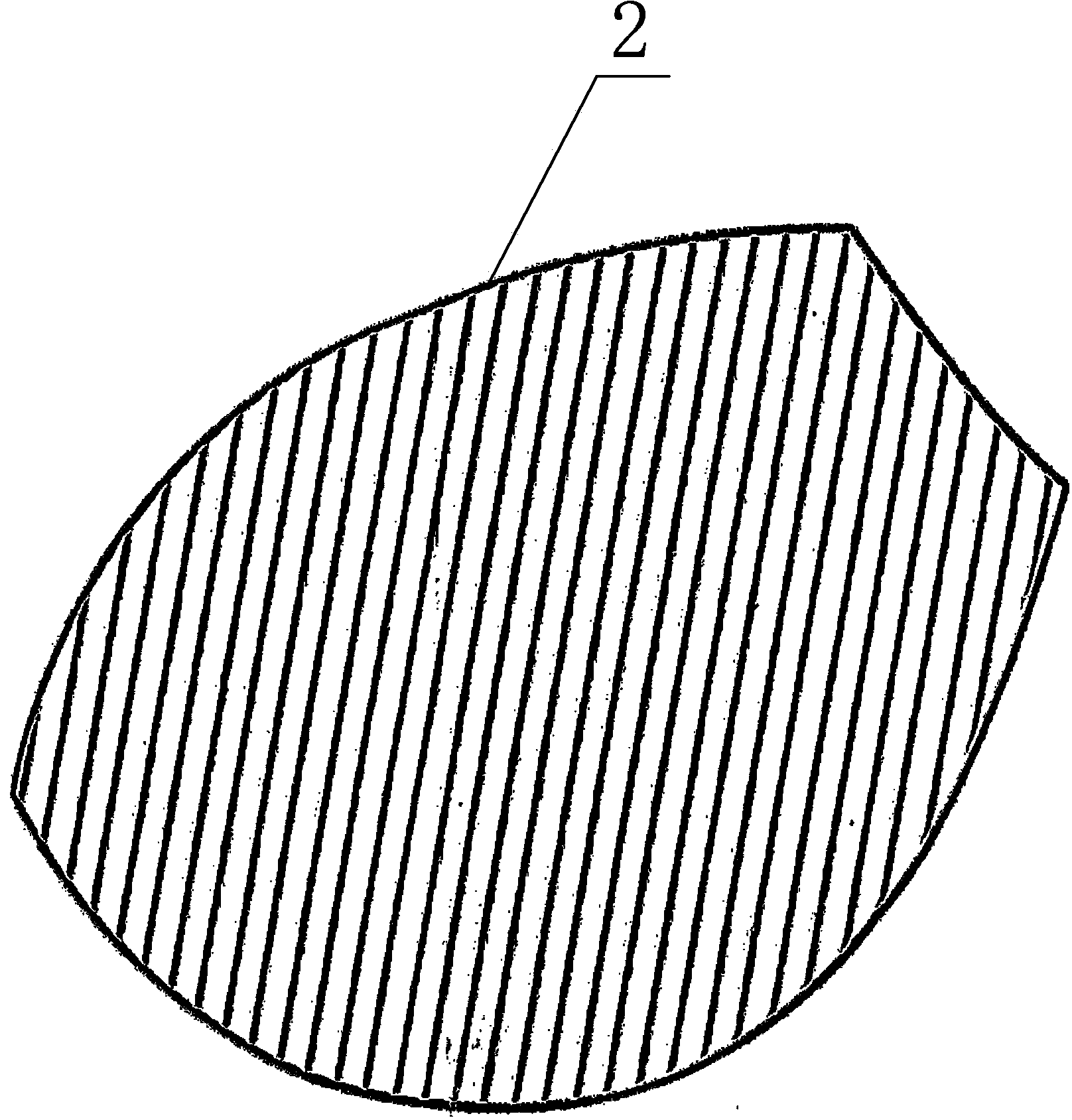

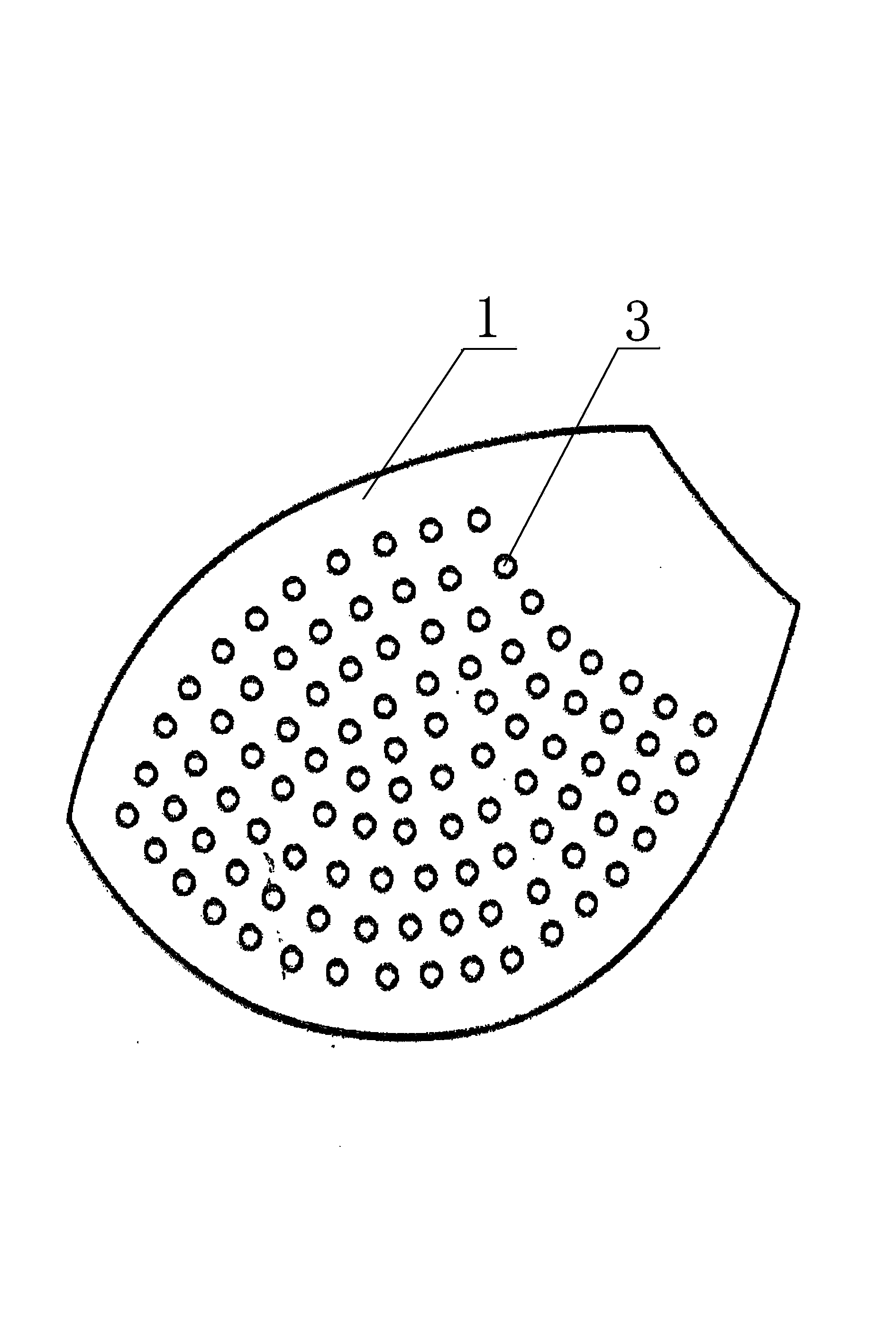

[0012] The invention discloses a composite sandwich breathable cup, which includes a cup body, which is different from the prior art in that the cup body is composed of an inner cup 1 and a surface cup 2 covering the surface of the inner cup 1, and there is one inner cup Air holes 3 are evenly distributed, and the diameter of the air holes 3 is 0.5mm-20mm.

[0013] During specific implementation, one surface of the inner cup 1 is covered with a front cup 2, and the other surface of the inner cup 1 near the lower edge forms an arc-shaped protruding strip edge 4, which is used to set off the lower edge of the chest. It has the effect of supporting height and concentrating the chest shape.

[0014] In a specific implementation, the upper edge and the lower edge of the strip-shaped flange 4 form a continuous arc-shaped connecting surface 5 with the other s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com