A Kovar metal structure and laser welding method for laser sealing welding

A technology of laser welding and sealing welding, which is applied in the direction of laser welding equipment, sealed casing, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

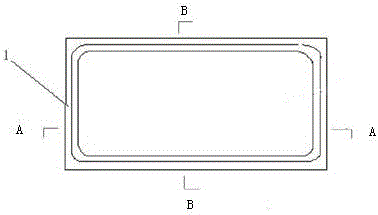

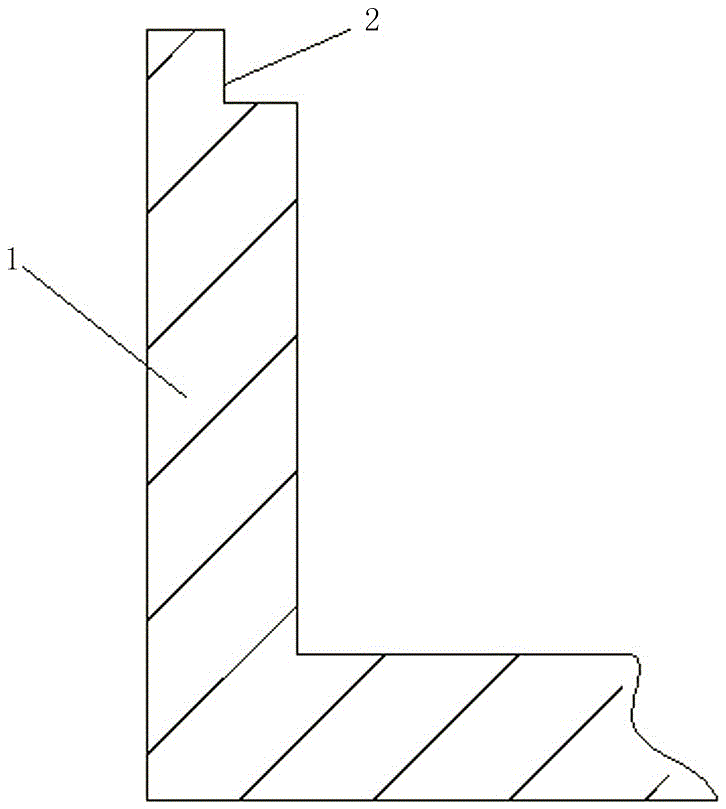

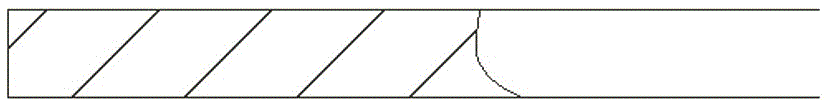

[0058] combine figure 1 -15. A Kovar metal structure for laser sealing welding. This embodiment is a regular geometrical structure. The cavity structure is a Kovar 4J33 material with a length of 20.00mm × width of 10.00mm × height of 5.00mm. Metal structure, the structure of the cover plate 3 is a Kovar metal structure made of 4J33 with a length of 19mm × width of 9mm × height of 0.50mm. The thickness of the cavity side wall 1 is 1 mm, so as to effectively reduce the space occupied by the cavity wall 1; Provide bearing support; the width of the step 2 is 0.5mm, so as to balance the size of the laser welding spot and the force of the support surface as much as possible; the height of the step 2 is 0.5mm; the thickness of the cover plate 3 is 0.5mm.

[0059] Preferably, the matching shape of the cavity and the cover plate 3 is a polygon, so as to meet the requirements of different hybrid integrated circuit sealing structures;

[0060]Preferably, the corners 5 of the cavity and...

Embodiment 2

[0064] combined with Figure 10 --15. Complete the design of the cavity and the cover plate 3 according to the design requirements of the module circuit. This embodiment is an irregular geometric structure. If such a structure is to be airtightly welded, parallel seams must not be used. Laser welding provides a good solution for such Kovar metal structures.

[0065] In order to reduce the processing difficulty and meet the requirements of later laser welding at the same time, the structure adopts a rounding treatment with a radius of 1.00mm.

[0066] In order to ensure that the gap 4 at the joint between the cavity and the cover plate 3 is not greater than 0.06 mm and as small as possible, the cover plate 3 is designed with positive tolerances.

[0067] A laser welding method, characterized in that it comprises the following steps:

[0068] Provide a Kovar metal structure for laser sealing welding;

[0069] Clean the cavity and the cover plate 3 with a cleaning solution to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com