In-situ stress test method for soft rock with multi-measuring points using sensing column

A testing method and sensing column technology, applied in soil material testing, material inspection products, etc., can solve problems such as inability to realize complete grouting of the whole hole section, and achieve stress values at test points, easy calculation, and grouting The effect of short setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

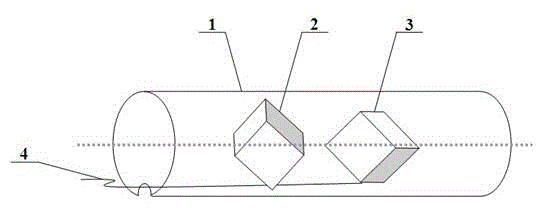

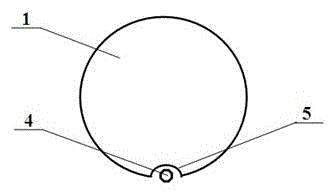

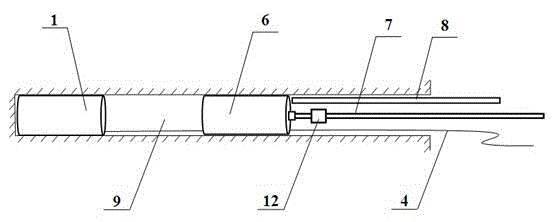

[0049] For soft rocks in coal-measure strata with a depth of 800 to 1000 meters, first make the corresponding stress sensing column 1, use the mold, and use the C2.5 grade cement mortar to wrap the two cube-shaped three-way pressure boxes 2 and 3 to form a cement A mortar cylinder with a diameter of about 120mm and a data line hole 5 on the side surface. The centers of the three-way pressure sensors 2 and 3 are both on the central axis of the stress sensing column 1 (cylindrical cement mortar body). The central axis of one end of the three-way pressure box 2 and 3 leads from the stress sensing column 1 forms a cylindrical groove during pouring, with a depth of 8 cm and the same diameter as the outer diameter of the push rod 7 . A cross bar made of stainless steel is fixed along the diameter of the cylinder in the groove, which becomes a connecting piece corresponding to the push rod 7 . The stress sensing column 1 is cured by adding water to 50% of the standard strength, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com