Method for reducing reserved width of waterproof coal pillars of inclined coal seam

A coal pillar and width technology, which is applied in the field of reducing the reserved width of waterproof coal pillars in inclined coal seams, can solve the problems of large reserved width of waterproof coal pillars, etc., and achieves the effects of improving the recovery rate, overcoming repeated calculation, and optimizing the width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

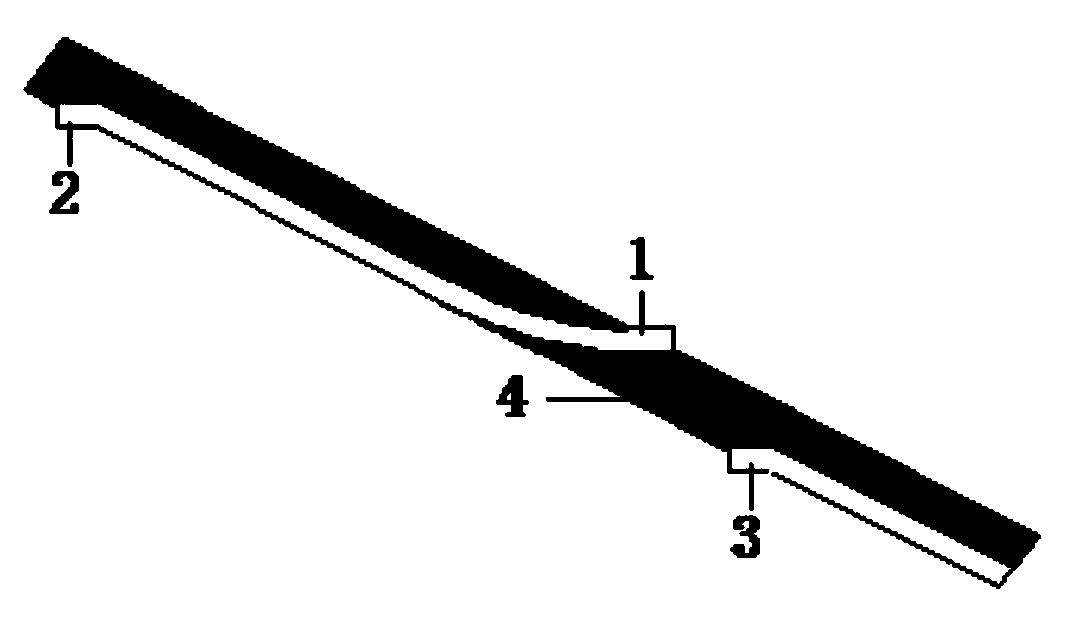

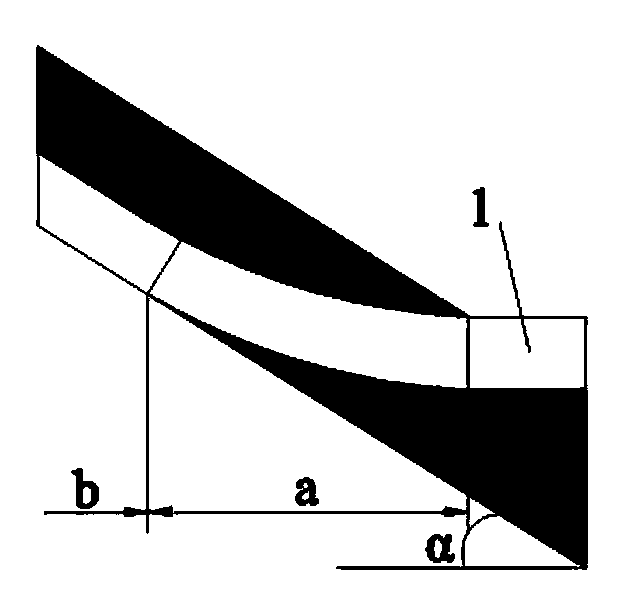

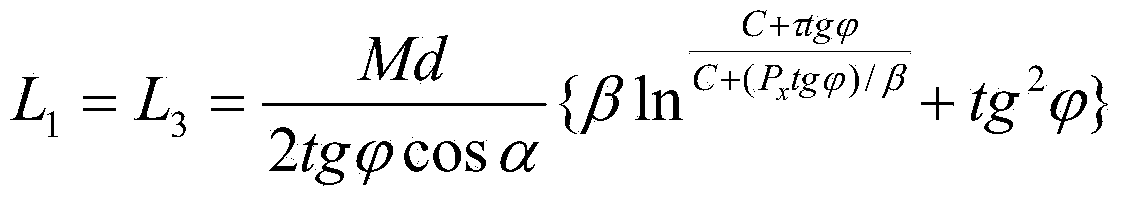

Image

Examples

Embodiment

[0052] A certain mine is designed to produce 1.2 million tons of mines per year, and the main mining coal seam is 4# coal seam. The average thickness of the coal seam is 6.2m, the inclination angle of the coal seam is 32°, the length of the working face is 150m, and the continuous advance range from the middle of the mine field to the east to the natural boundary is about 2100m. The coal seam structure and geological structure are both simple, and the comprehensive mechanized top-coal caving one-time full-height mining method is adopted. Before the method of the present invention is used for optimization, the two lanes (inlet air lane and return air lane) of the working face are arranged along the coal seam floor , the production practice at the working face that has been recovered shows that the normal water inflow is 5m 3 / min, the maximum water inflow is 8m 3 / min, the vertical height of the working face that has been recovered is 80m, and the water in the goaf of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com