Sewing machine with dust collection device

A vacuum device, sewing machine technology, applied in the field of sewing machines, to achieve the effect of ensuring air quality, avoiding pollution, and eliminating dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

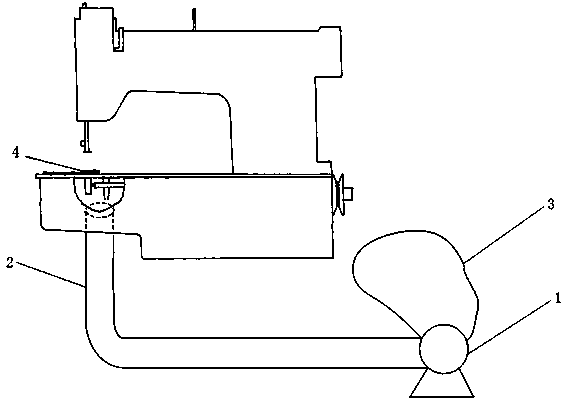

Image

Examples

Embodiment 1

[0016] In this embodiment, the suction port of the suction duct 2 is installed under the needle plate 4 of the sewing machine to vacuum the place where dust is easily generated inside the sewing machine base, and then use the suction generated by the impeller of the fan 1 to pass the dust through the suction duct 2 Inhaled into the dust collection bag 3, eliminating the dust generated during sewing, avoiding the accumulation of dust on various movable parts, reducing the possibility of sewing machine failure; avoiding the pollution of dust to the workshop environment, Ensure the air quality of the workshop.

[0017] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention shall be included in the protection of the present invention. within range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com