Five-end-riser aluminum electrolysis tank bus configuration structure

A technology of aluminum electrolytic cell and configuration structure, which is applied in the field of ferrofluid stable busbar configuration structure of large aluminum electrolytic cell, which can solve the problems of insufficient magnetic field compensation and damage to electrolytic cell stability, and achieve the effect of saving the amount of busbar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

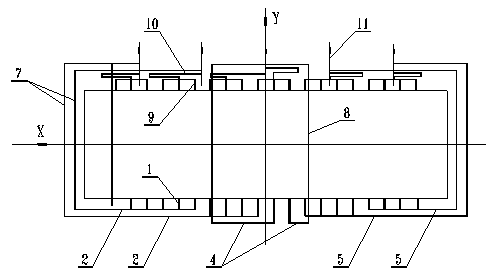

[0014] Embodiment of the present invention: 5 upright column busbars on the power inlet side and 5 upright column busbars on the power outlet side are set, that is, the upstream electrolyzer, this electrolyzer and the downstream electrolyzer are respectively provided with 5 upright column busbars on the power inlet side and 5 outlet side Electric side upright busbar. 5 upright column busbars on the power inlet side are connected to 2 sets of anode busbars in the upper structure of the tank, and the 2 sets of anode busbars are respectively connected to 20 sets of anodes, 20 sets of cathode carbon blocks and 20 sets of cathode steel rods; 20 groups of cathode soft busbars welded by steel rods 1 are connected to the cathode busbars 2 on the inlet side of the flue end, the cathode busbars on the middle inlet side 4, and the cathode busbars 5 on the inlet side at the aluminum outlet end, and pass through the side busbars 7 on both sides of the electrolytic cell, The busbars 8 passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com