Method for configuring bus bar of aluminum electrolytic bath

A busbar configuration and electrolytic cell technology, which is applied in the field of busbar current configuration around large-scale aluminum electrolytic cells, can solve the problems of production operation hazards, poor cell stability, and excessive local magnetic field of electrolytic cells, so as to save bus consumption and improve Design and production requirements, the effect of meeting stability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

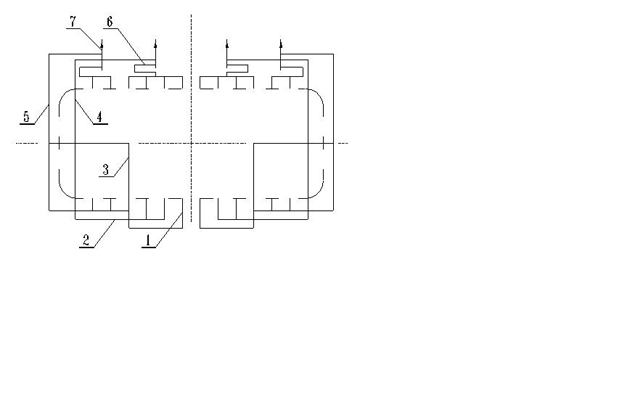

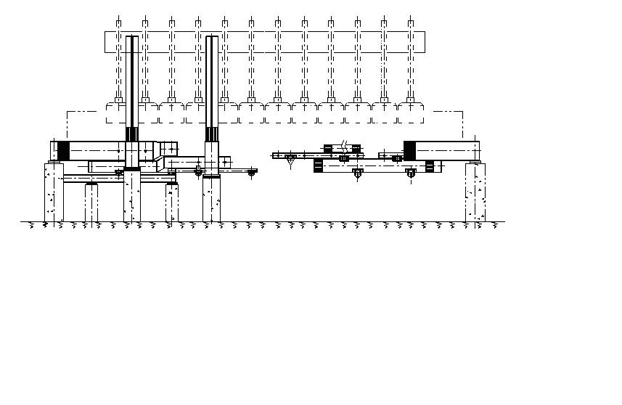

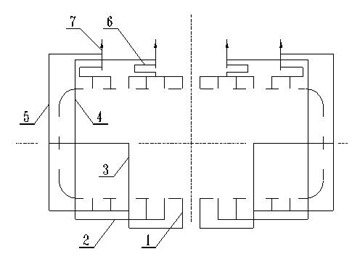

[0010] Example 1: During the production of the electrolytic cell, the direct current enters the four column busbars 7 on the power supply side of the cell from the upstream electrolyzer, and the current enters the anode busbar of the upper structure of the cell through the four column busbars 7 of the same current, and then distributes to 12 sets of anodes, and then flow through the molten electrolyte layer, aluminum liquid layer in the tank, 12 sets of cathode carbon blocks, and 12 sets of cathode steel rods, and then pass through 12 sets of cathode soft busbars welded with cathode steel rods on the power supply side 1 Lead in the cathode busbar 2 on the power supply side, and then flow into 2 busbars at the bottom of the zigzag groove 3, 2 through busbars at the bottom of the groove 4, 2 busbars at the side of the groove 5, and 2 busbars at the bottom of the zigzag groove 3 respectively merge into two busbars on the side of the tank, and then pass through the busbars 4 and bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com