Remote locking and anti-theft system for automated factory vehicles and its work flow

An anti-theft system and workflow technology, applied to anti-theft vehicle accessories, vehicle parts, transportation and packaging, etc., can solve the problems of ineffective prevention of bad guys' invasion, criminals' easy discovery and hiding, and hindering the appearance, etc., to achieve Save consumables, ensure accuracy, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

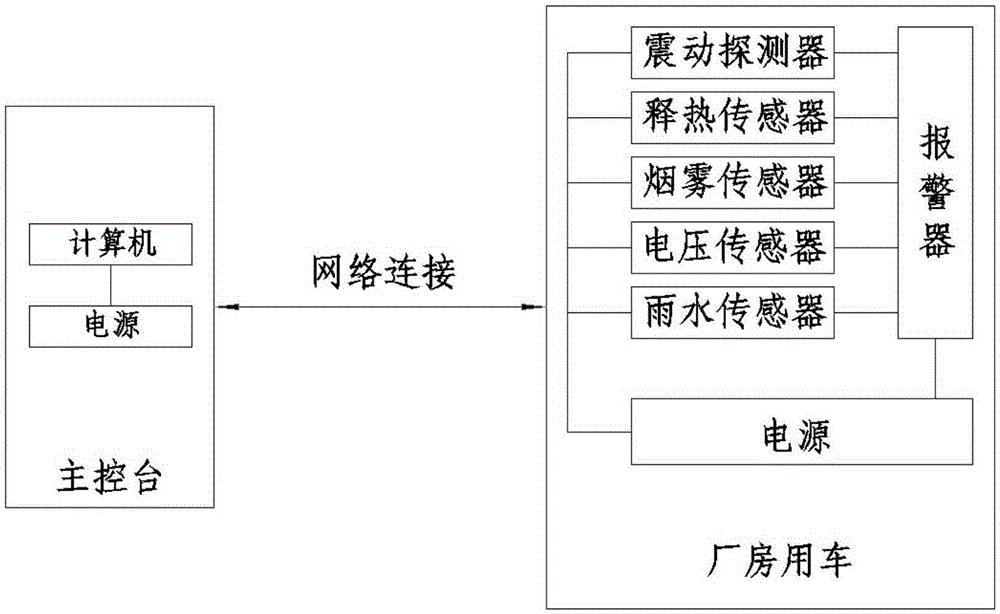

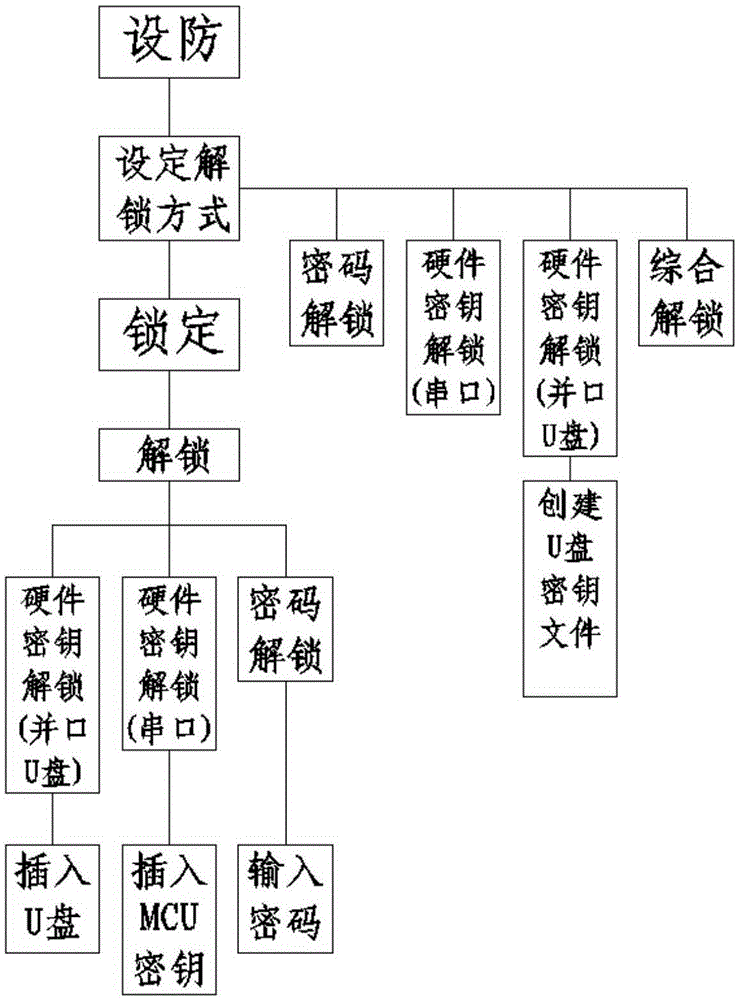

[0030] figure 1 and figure 2 A specific embodiment of the present invention is shown, figure 1 is the system structure diagram, figure 2 It is a flow chart of the system work; figure 1 As shown, the remote locking and anti-theft system for automated factory vehicles includes a factory vehicle end composed of vehicles and a main console for remote monitoring of factory vehicles; the above vehicles are at least installed with vibration detectors, heat release Sensors, alarms, and power supplies that provide electric energy for the vehicle end of the factory building. The alarm device is provided with a sensor interface, and the vibration detector and the heat release sensor are connected to the alarm through the sensor interface; the vehicle end of the factory building is connected to the Main console communication; the main console is at least equipped with a computer and a power supply that provides electrical energy for the computer; monitoring software is running on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com