Glass run and method of assembling door glass on glass run

一种玻璃滑槽、车门玻璃的技术,应用在挡风玻璃、密封装置、密封装置等方向,能够解决负载小、追随不充分、内接唇6X挠曲量大等问题,达到提高生产性、提高装配作业性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

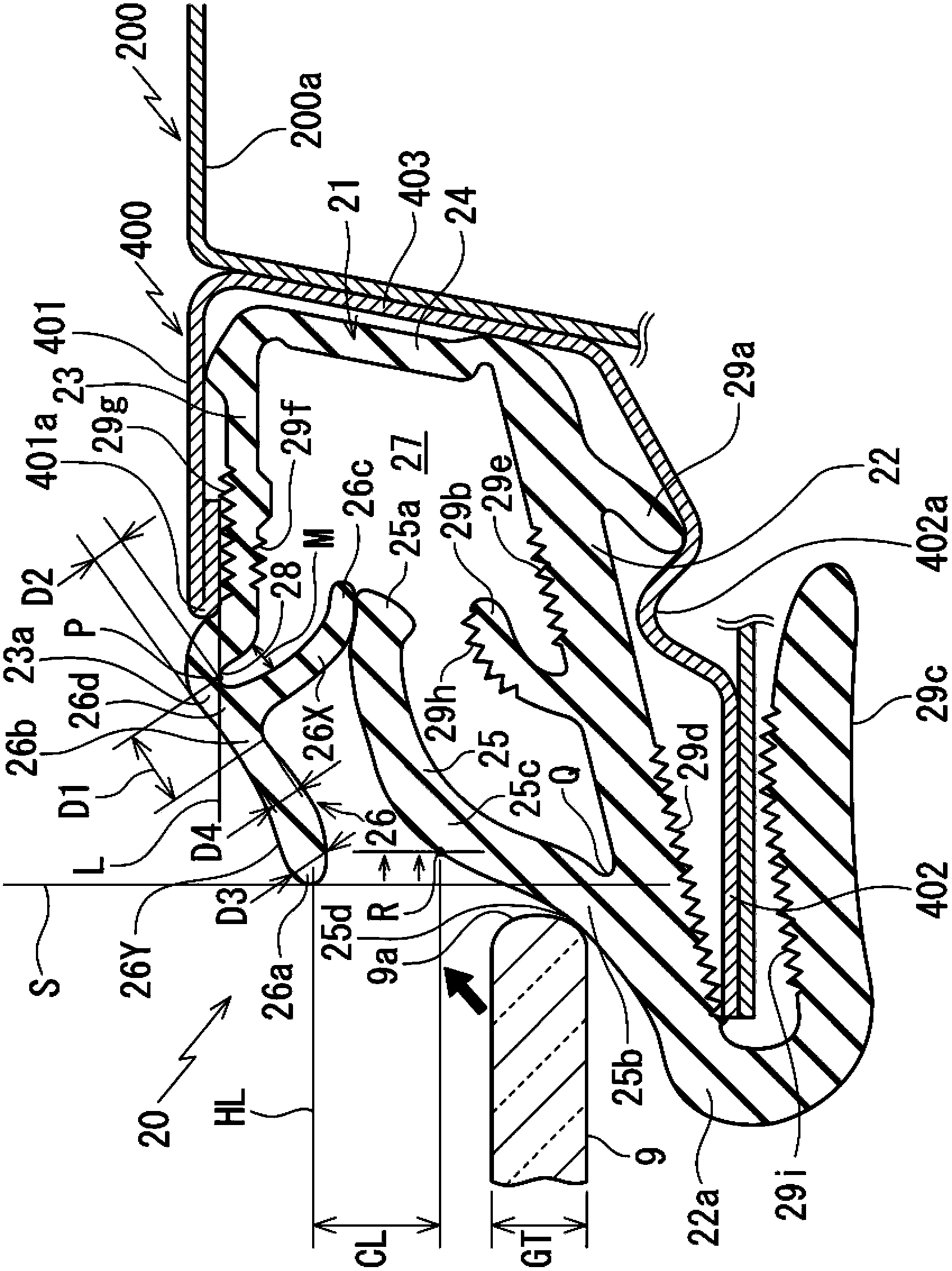

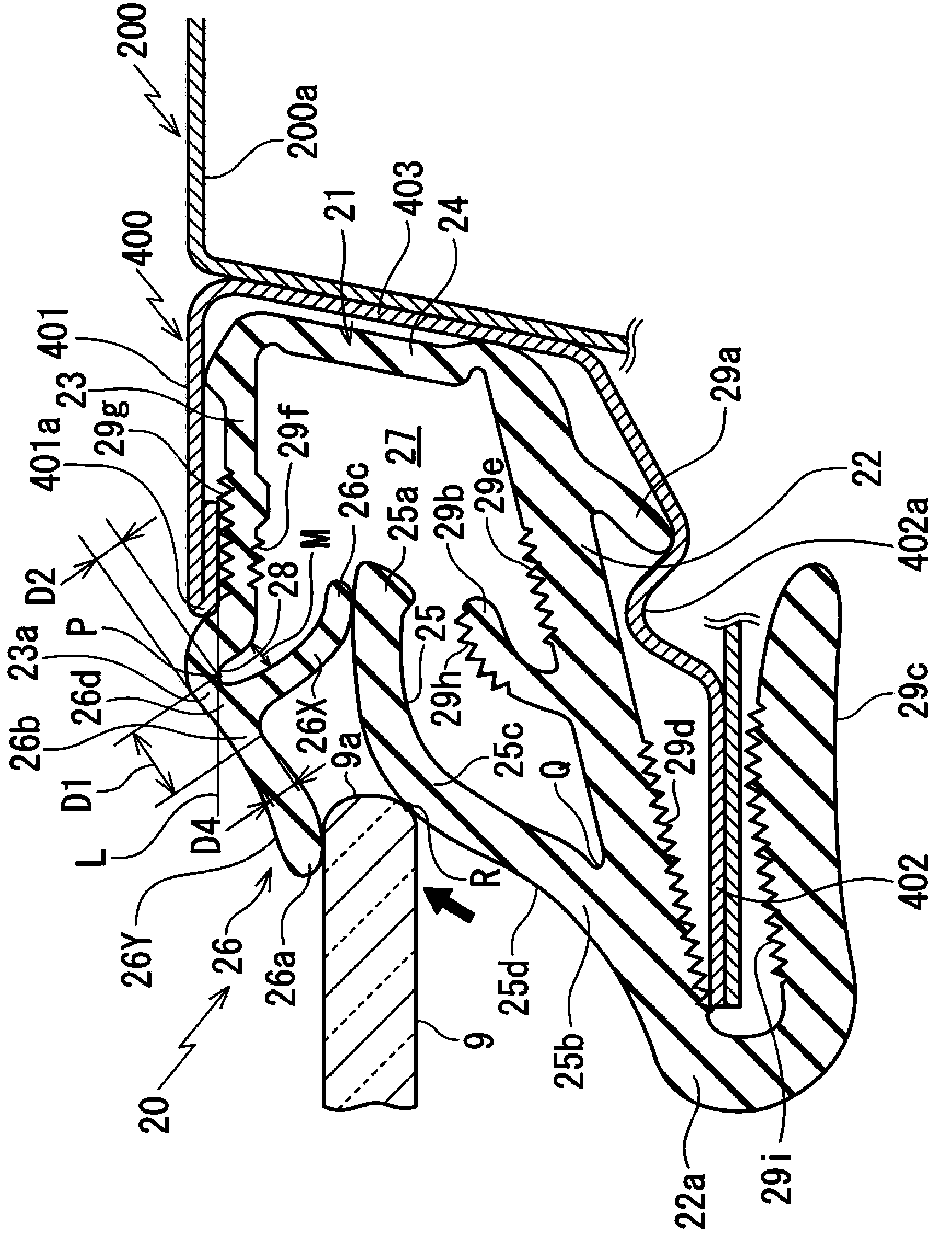

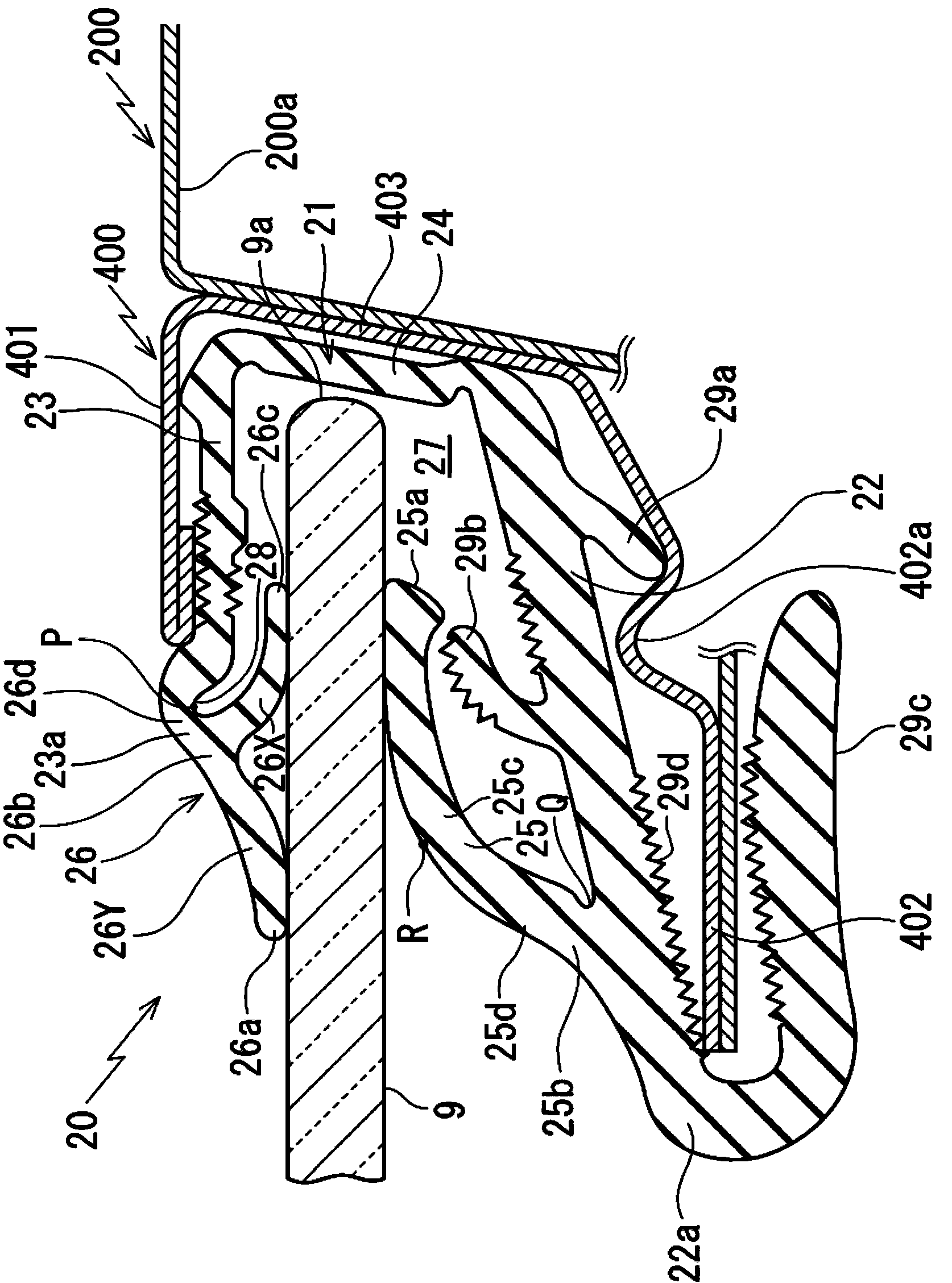

[0114] refer to Figure 1 to Figure 3 , the glass run channel 20 according to the embodiment of the present invention will be described. figure 1 and figure 2 It shows step by step how the door glass 9 is guided when the door glass 9 is assembled using the glass run channel 20 according to the embodiment of the present invention. Figure 9 The enlarged sectional view of the A-A line, the final state where the door glass 9 is guided is image 3 . In addition, the same code|symbol is attached|subjected to the same part as the member illustrated conventionally.

[0115] The glass run channel 20 according to the embodiment of the present invention is fitted into a door sash (frame) 400 to guide the door glass 9 being raised and lowered into the groove portion 27, and the door sash (frame) 400 is attached by spot welding. On the door panel 200 a of the front door 200 (the same applies to the rear door 300 ) of a press door type. In addition, the glass run channel 20 is appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com