Device with tightening and tailing cutting functions

A technology of tailings and main devices, which is applied in the field of automatic tightening of automobile zipper ties, can solve the problems of long operating hours, low production efficiency, and failure to reach products, and achieve high production efficiency, labor saving, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

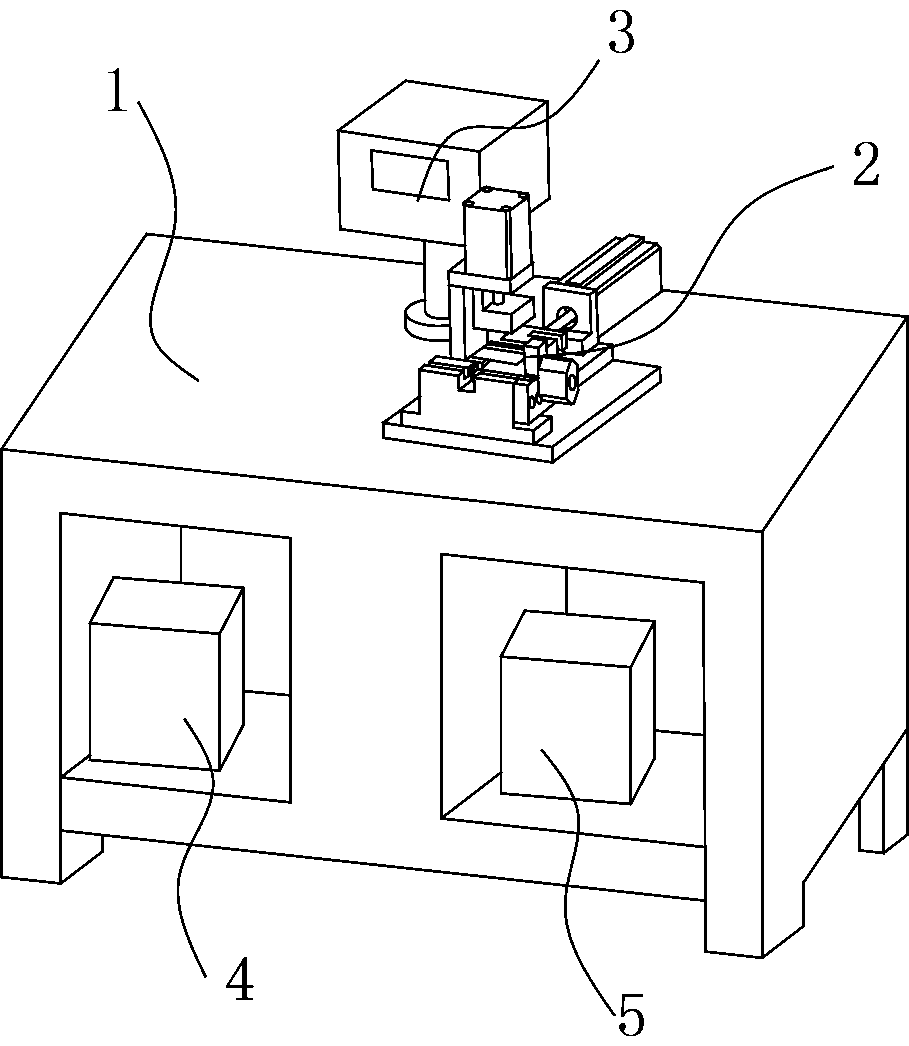

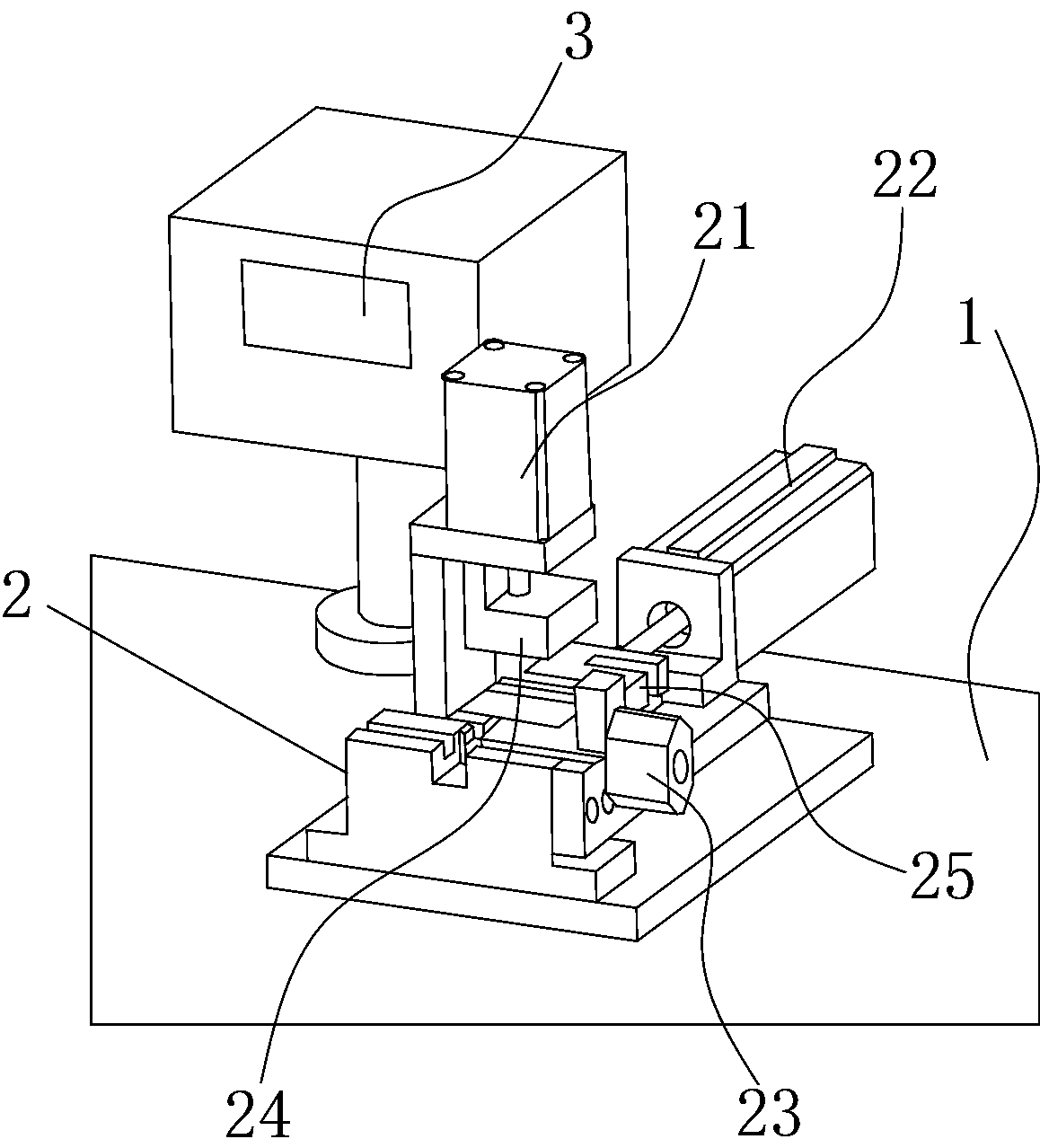

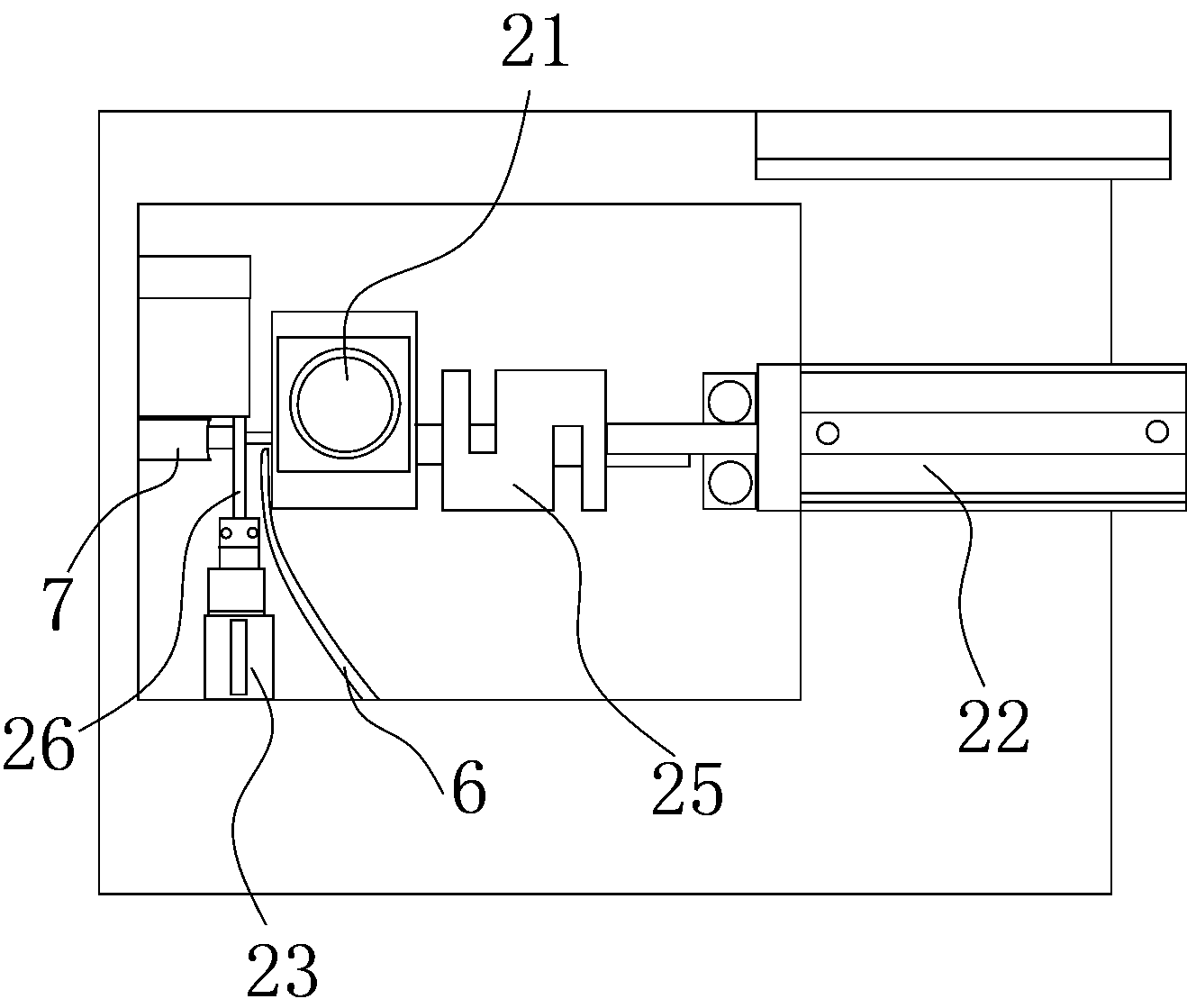

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1~Figure 3 , a device for tightening and cutting tails, comprising a workbench 1, a main device 2, and a digital display 3, the main device 2 and the digital display 3 are arranged on the workbench 1, placed under the workbench 1 Tie accessories box 4 and tail material collection box 5 are arranged. The cable tie accessory box 4 is used to place the cable tie, and the tail material collection box 5 is used to collect the tail material.

[0013] The main device 2 includes a No. 1 cylinder 21 , a No. 2 cylinder 22 , a No. 3 cylinder 23 , a fixture 24 , a tension sensor 25 and a cutter 26 . The No. 1 cylinder 21 controls the clamp 24 to press down, and the clamp 24 presses down to compress the cable tie.

[0014] The No. 2 cylinder 22 controls the clamp 24 to move backward to tighten the cable tie. The tension sensor 25 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com