LTD module and synchronous trigger method thereof

A circular direction and branch technology, which is applied to the LTD module and its synchronous trigger field, can solve the problems of the large and complex trigger pulse generation system of the trigger circuit topology structure, and cannot be used as a LTD branch switch, etc., to improve the trigger reliability and simplify the requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

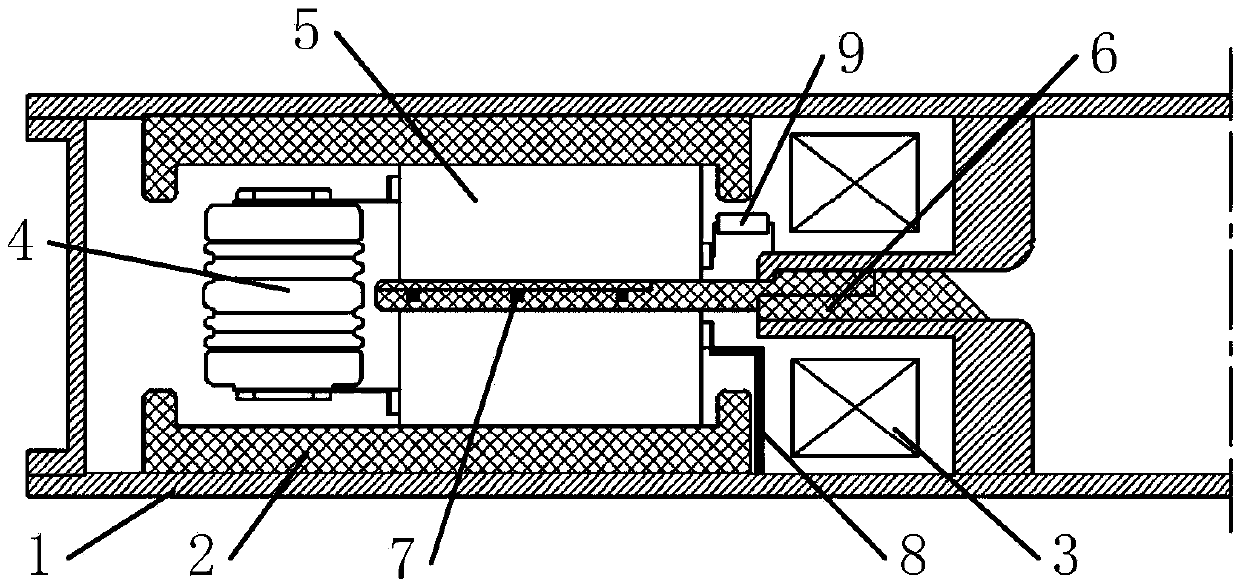

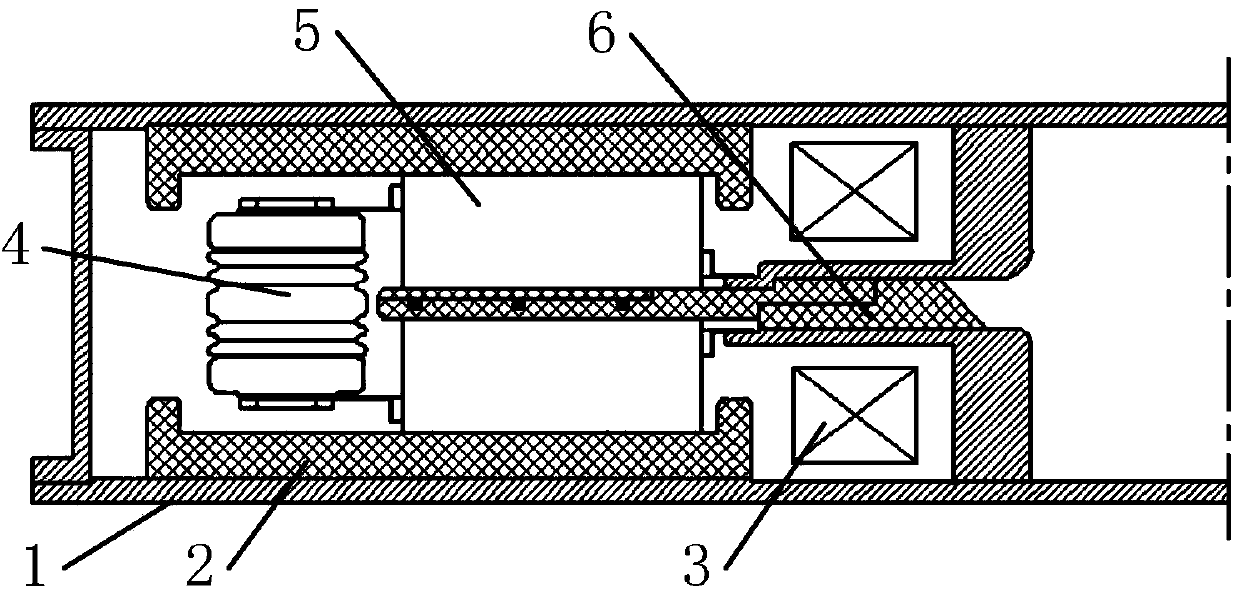

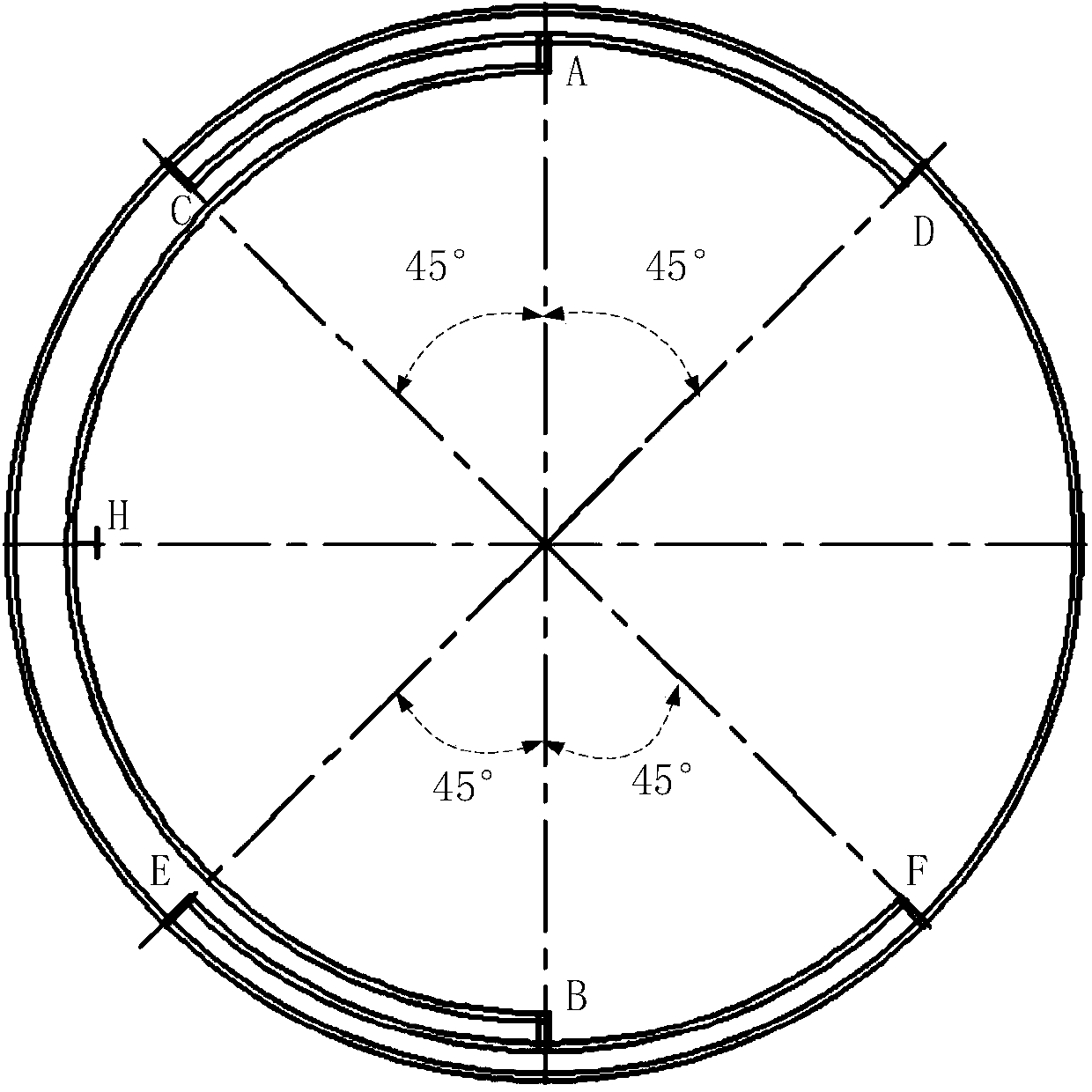

[0030] The core idea of the present invention is to introduce a fast leading-edge trigger pulse and use a branch placed inside the LTD module. One end of the branch is grounded, and the other end is connected to the secondary external of the coupled magnetic core through a high-resistance load formed by a spiral resistance wire. The high-voltage output end is connected to the angular transmission line placed in the middle of the module at the same time; the angular transmission line transmits 1 / 4 of the circumference to two points A and B along the circumferential direction, and transmits from the two points A and B respectively along the circumferential direction 1 / 8 circle, reaching C, D, E, F four points, connected to the metal trigger ring on the outside of the intermediate insulator, from the metal trigger ring through the isolated inductance formed by the spiral resistance wire to the trigger electrodes of the other branch switches to realize the branch circuit The swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com