Rotate speed differential device

A speed difference and speed sensor technology, applied in the field of speed differential devices, can solve problems such as production cannot be carried out normally, damage, squeezing roller collision, etc., and achieve the effect of avoiding mutual jamming and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

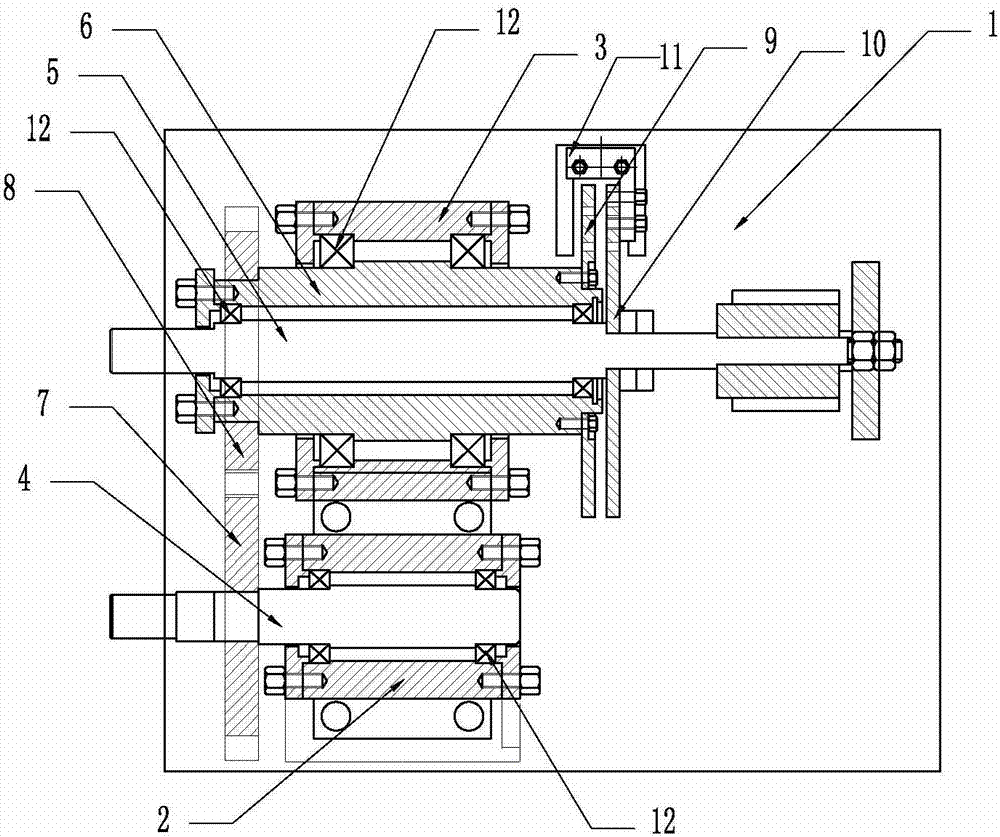

[0007] Such as figure 1 As shown, a speed differential device is characterized in that it includes a base 1, a bearing seat I2, a bearing seat II3, a rotating shaft I4, a rotating shaft II5, a sleeve shaft 6, a transmission gear I7, a transmission gear II8, a rotary piece I9, and a rotary piece II10, speed sensor 11 and bearing 12; bearing housing I2 and bearing housing II3 are installed side by side on base 1, rotating shaft I4 is installed in bearing housing I2 through bearing 12, sleeve shaft 6 is installed in bearing housing II3 through bearing 12, rotating shaft II5 Installed in the sleeve shaft 6 through the bearing 12, the two ends of the shaft II5 protrude from the sleeve shaft 6, and a transmission gear I7 is installed at the front end of the shaft I4; a transmission gear II8 connected with the teeth of the transmission gear I7 is installed at the front end of the sleeve shaft 6, A rotary piece I9 is connected to the rear end of the sleeve shaft 6; a rotary piece I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com