A kind of analysis method of lysine fermented liquid

A technology of lysine fermentation broth and lysine, which is applied in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problems of long time, asynchronous amino nitrogen content, and high risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

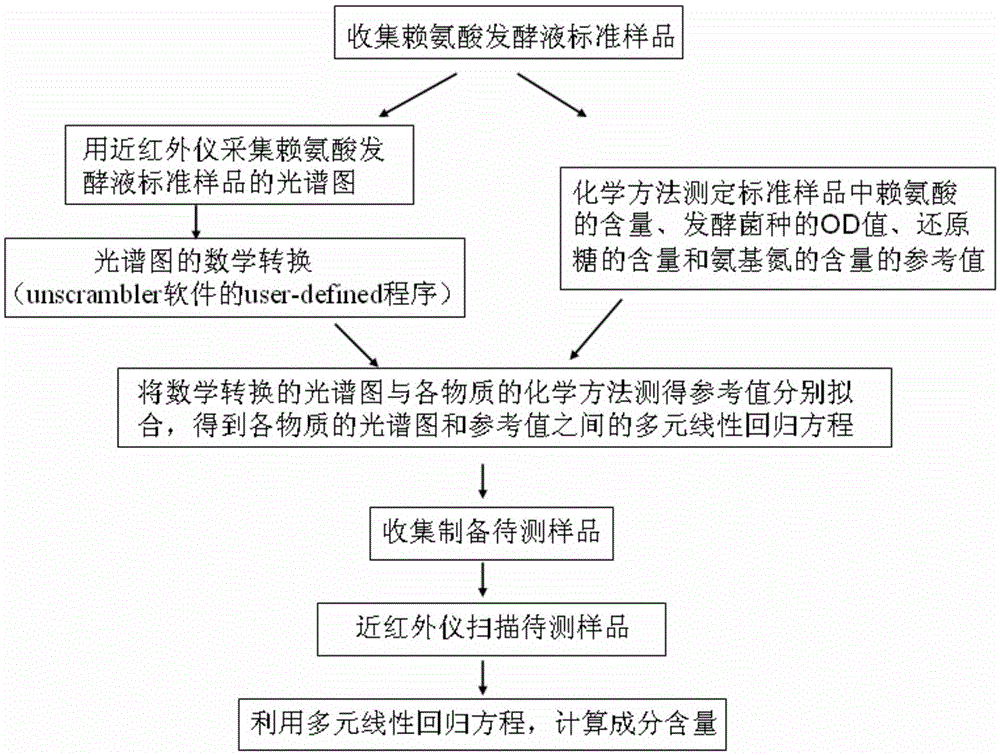

Method used

Image

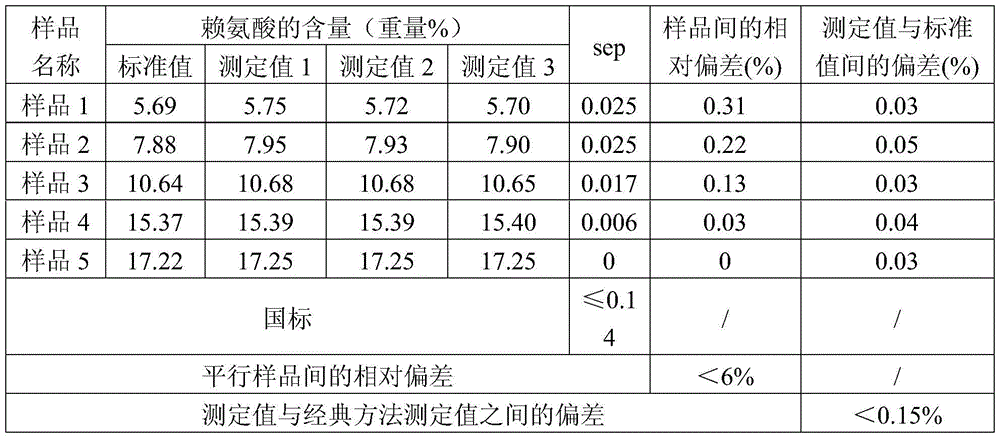

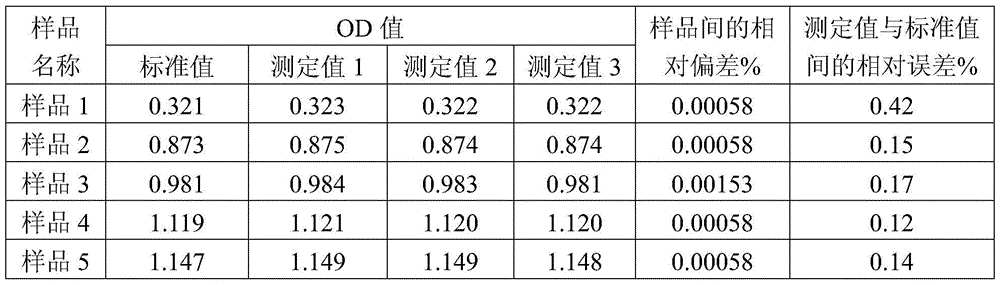

Examples

Embodiment

[0041] (1) Creation of CDF file

[0042] (1) Maintain the standard samples of lysine fermentation broth in four different temperature ranges of 24°C to less than 26°C, 26°C to less than 28°C, 28°C to less than 30°C, and 30-33°C, each temperature The number of standard samples of lysine fermentation broth in the range is 60. Wherein, the content of lysine is between 0-20% by weight; the OD value of the fermentation strain is between 0-2; the content of reducing sugar is between 0-3% by weight; the content of amino nitrogen is between 0-0.3 between weight %. And the substance measured in the lysine fermentation liquid standard sample taken in each temperature range is on the basis that the content is 0, and the content of lysine increases successively with the content difference of 0.2-0.4% by weight; The value increases successively with a difference of about 0.02-0.04; the content of reducing sugar increases successively with a difference of about 0.02-0.06% by weight; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com