Splicer devices and winders for splicing yarns

A splicer and winding machine technology, applied in the field of winding machines, can solve the problems of complex pneumatic splicing process and extremely complex requirements of yarn, and achieve the effect of cost-effectiveness and efficiency advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

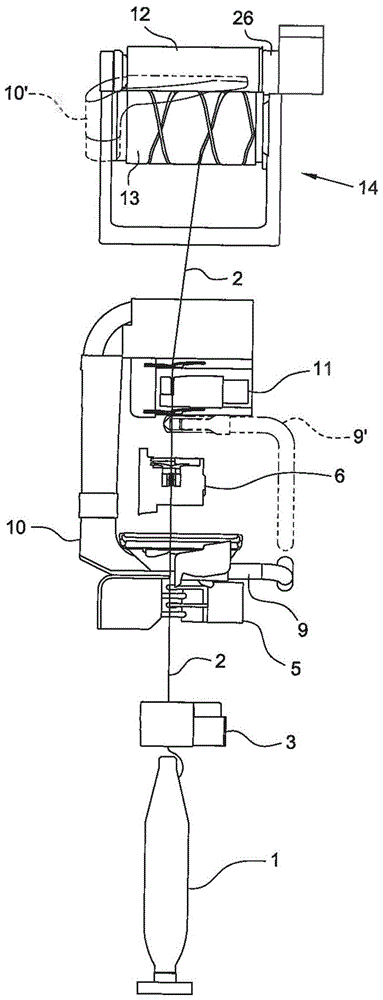

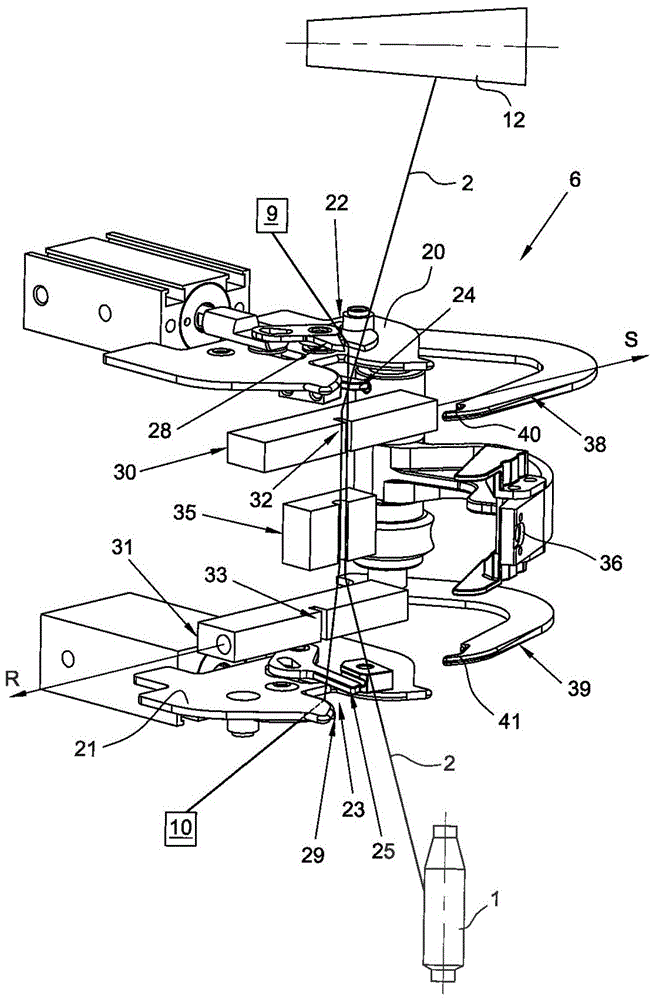

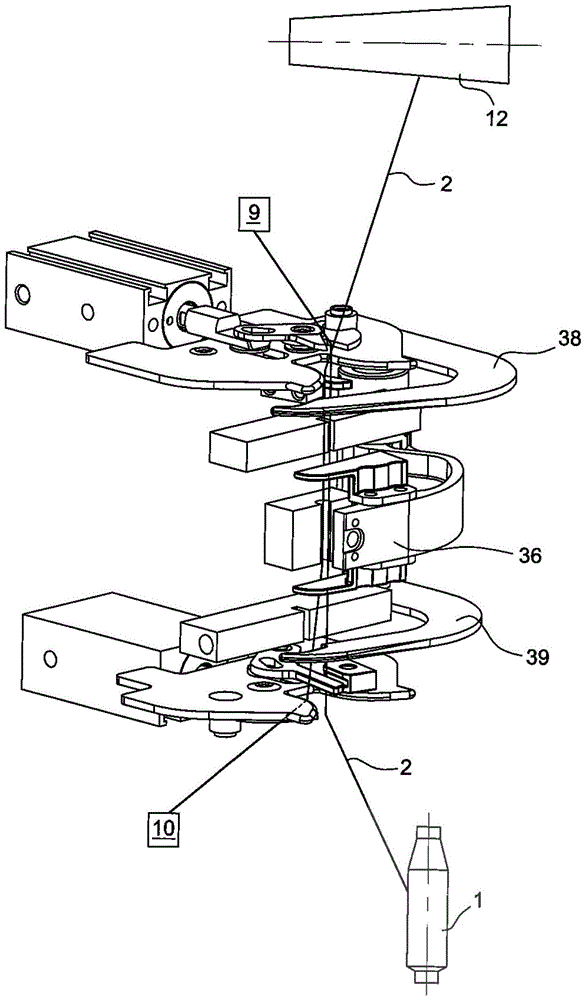

[0041] figure 1 A diagram of the yarn collection unit in the winder is shown in the form of a front view, in which the most important elements involved in the process of forming the package are shown and technical issues are explained. Figures 2A-2G The steps of the yarn splicing process with the splicer device according to the invention are shown with reference to an exploded view of the main elements of the splicer device according to the invention.

[0042] Figure 2A The splicer arrangement is shown in initial step 1, where the yarn ends are brought to the splicer from the pack side inlet and the feed rocker side inlet, with the following components shown in exploded view:

[0043] 20, 21: upper and lower guide plates of the yarn leading to the splicer, wherein, according to one embodiment, these upper guide plates 20 and lower guide plates 21 are made to be fixed plates;

[0044] 22, 23: upper yarn guide cavity and lower yarn guide cavity,

[0045] 24 , 25 : upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com