A shaft protection sleeve for a vertical shaft pulverizer

A pulverizer and protective cover technology, applied in grain processing and other directions, can solve problems such as scratching the pulverizer, loss, raw material wear, etc., and achieve the effects of good protection, reasonable structure and extended use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

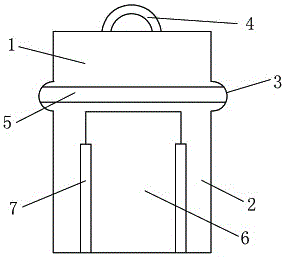

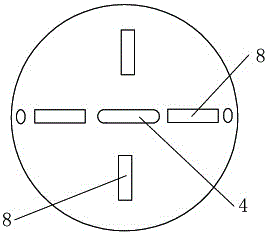

[0011] Combine below figure 1 and figure 2 Specific description embodiment:

[0012] A shaft protection sleeve of a vertical shaft pulverizer, characterized in that the shaft protection sleeve of the vertical shaft pulverizer includes an upper sleeve 1 and a lower sleeve 2, and an arc-shaped sleeve is arranged between the upper sleeve 1 and the lower sleeve 2 3. The arc-shaped sleeve 3 protrudes outward, the top of the upper sleeve 1 is provided with a pull ring 4, the arc-shaped sleeve 3 is provided with a through hole 5, and the through hole 5 runs through the arc shaped sleeve 3, the lower sleeve 2 is a cylinder, the lower sleeve 2 is provided with a shaft hole 6, and the lower end of the shaft hole 6 is provided with a sheath 7.

[0013] Preferably, the upper part of the upper cover 1 is provided with several mutually symmetrical reinforcement pieces 8 , and the reinforcement pieces 8 are distributed around the pull ring 4 around the pull ring 4 .

[0014] The shaft pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com