Oblique type hole tray seedling transplanting paw

A technology of plug seedlings and oblique insertion, which is applied in the direction of transplanting machinery, application, agriculture, etc., can solve the problems of high cost, high labor intensity, and many driving sources, so as to reduce the production cost, ensure the holding ability, and avoid The effect of the seedling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

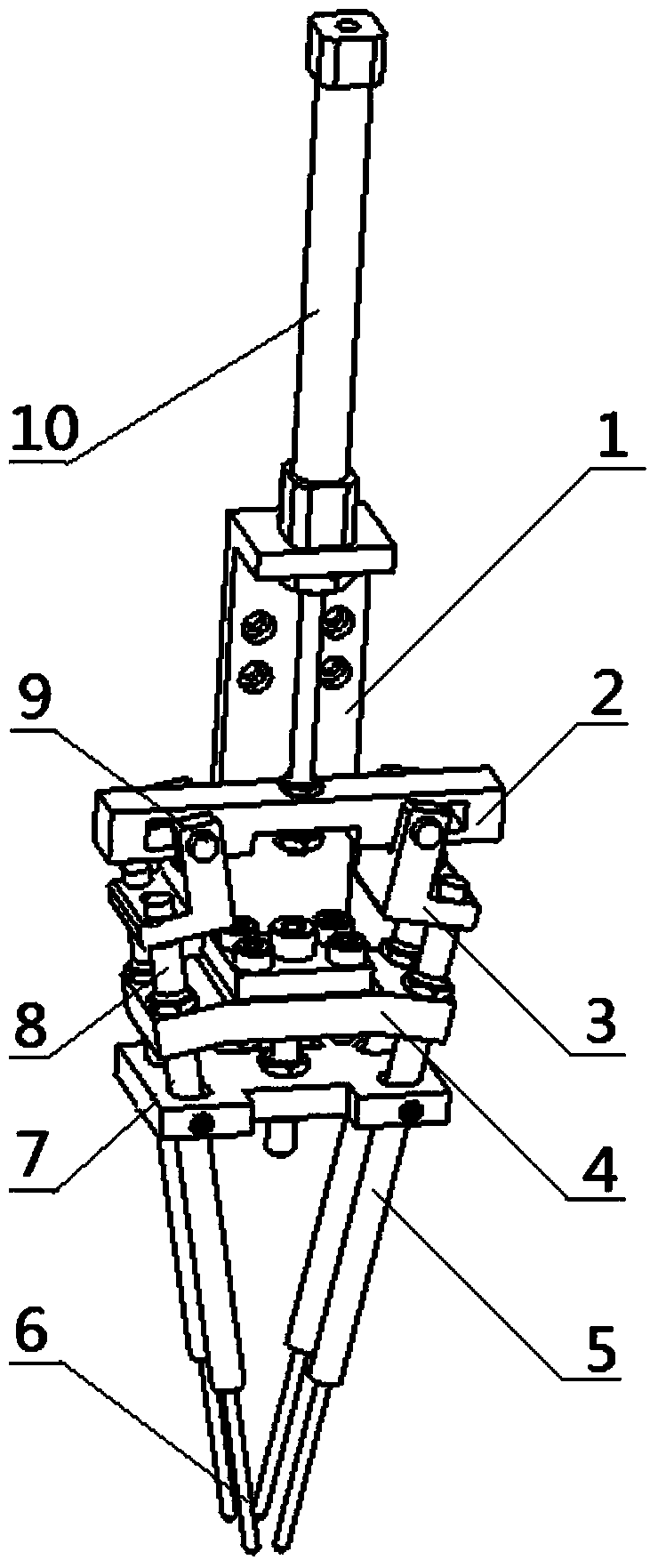

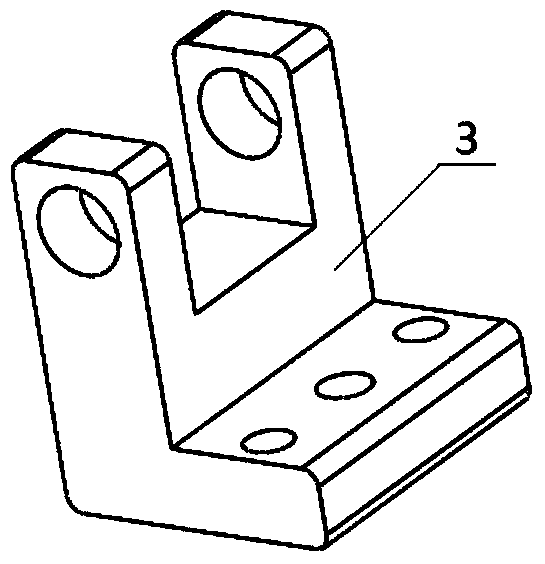

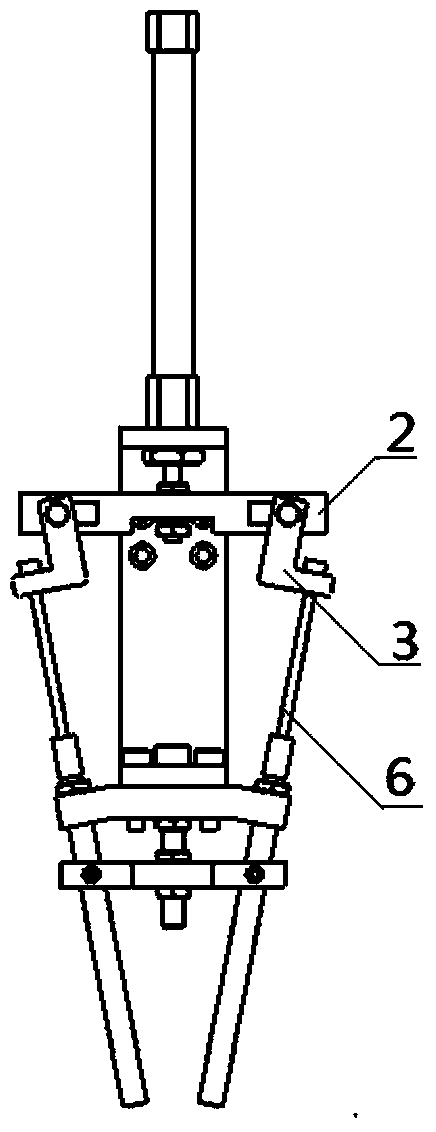

[0016] Such as figure 1 , figure 2 As shown, the inclined-in plug-in seedling transplanting claw includes a frame 1, a sliding table 2, a steel needle fixing plate 3, a sleeve fixing plate 4, a sleeve 5, a steel needle 6, a reinforcing plate 7, and a buffer sleeve 8. The pin shaft 9, the cylinder 10, the frame 1 is a U-shaped structure, and the cylinder 10 is fixed on the upper part; the sliding table 2 is a symmetrical structure, and two long holes are symmetrically opened on both sides, and the middle part of the sliding table 2 is fixed on the cylinder 10. The end of the push rod; the section of the steel needle fixing plate 3 is an L-shaped structure, and the two pin shafts 9 are respectively fixed on the upper parts of the two steel needle fixing plates 3, and the two pin shafts 9 are installed in the long holes on both sides of the sliding table 2, It can drive tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com