Device and method for detecting perpendicularity of template

A detection device and verticality technology, which is applied to the template verticality detection device and its detection field, can solve the problems of time-consuming and labor-intensive detection result quality, low quality detection result, troublesome detection, etc., and achieve reduced acceptance time, fast speed, The effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

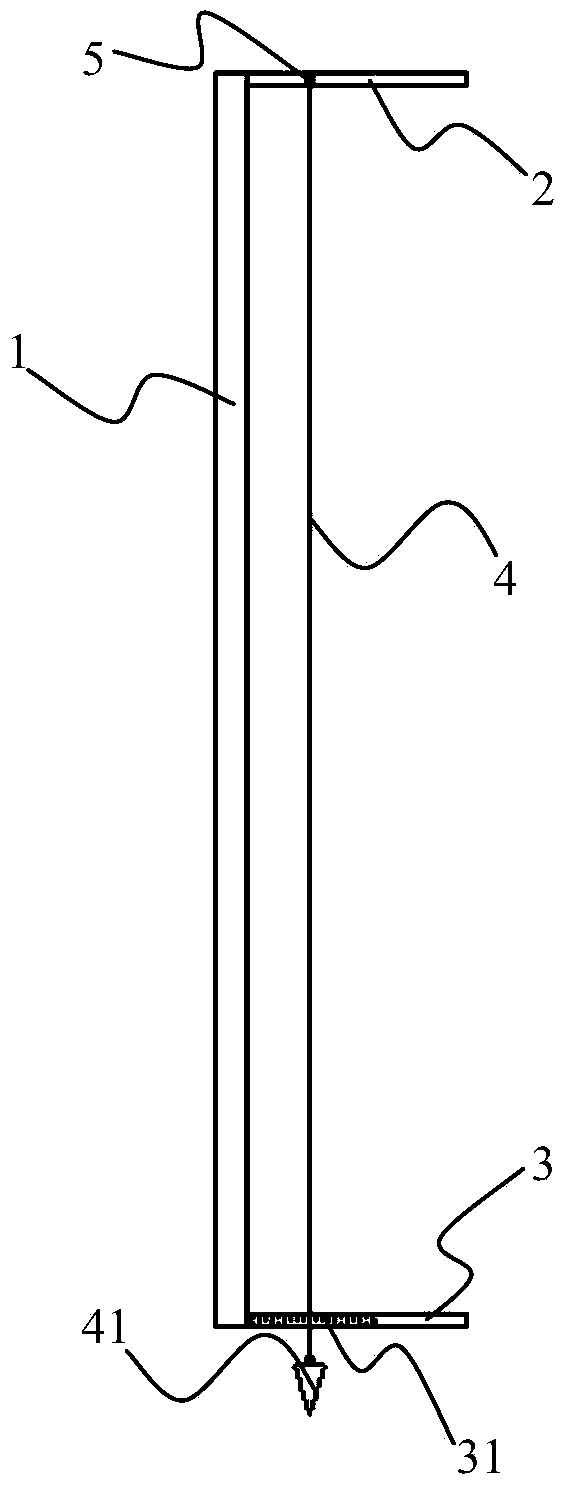

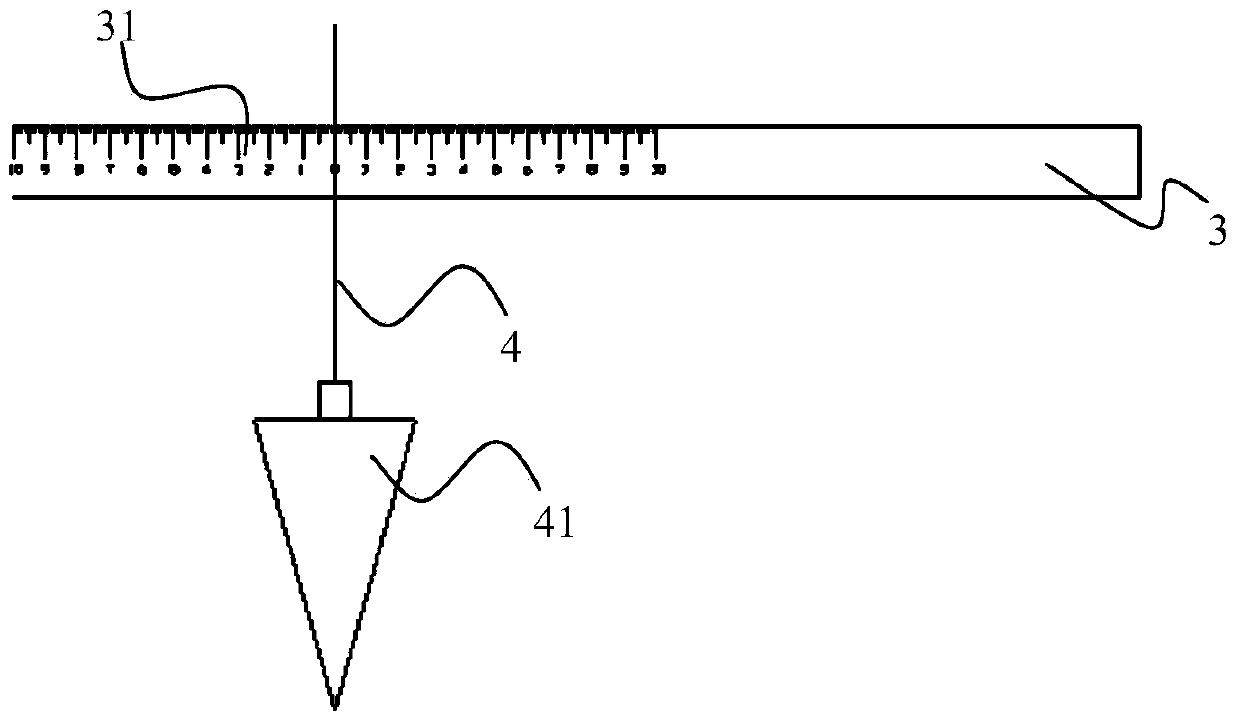

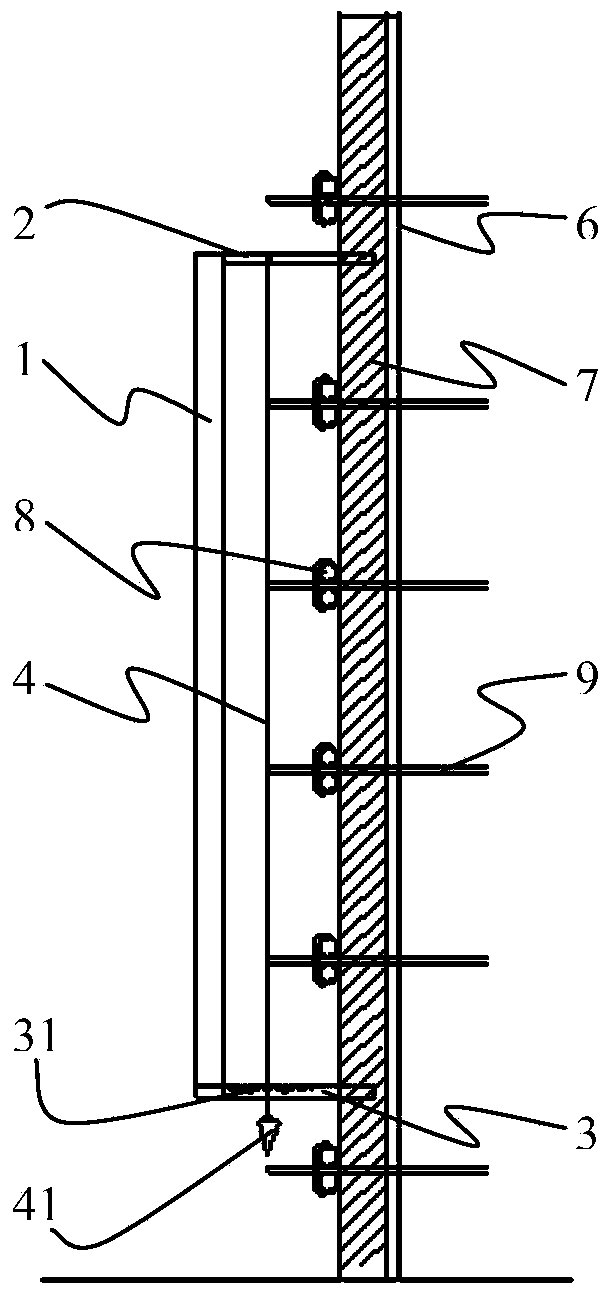

[0023] see figure 1 As shown, it is a structural schematic diagram of the template verticality detection device of the present invention. The template verticality detection device is a frame structure, and the frame structure includes a support rod 1, an upper leg 2, a lower leg 3, an upper leg 2 and a lower leg 3 Vertically connected to both ends of the support rod 1, the upper leg 2 and the lower leg 3 are parallel and equal in length. The template verticality detection device also includes a hanging wire 4, the hanging wire 4 is fastened on the upper leg 2 through the nail 5, the bottom of the hanging wire 4 is connected to the wire pendant 41, and the length of the hanging wire 4 is greater than the length of the support rod 1. refer to figure 2 As shown, the lower leg 3 is provided with a scale 31, the vertical position scale of the sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com