Drill rod structure with high-station structure, and manufacturing method

A high-station, processing method technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of puncture, easy corrosion, and high labor intensity of workers.

Active Publication Date: 2013-12-25

SHANGHAI HILONG DRILL PIPE MATERIALS INST +2

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Make-up and break-out of standard drill pipe generally requires drilling workers to confirm the make-up and operate hydraulic tongs. Because the distance between the clamping part of the standard drill pipe joint hydraulic tongs and the well platform is short, the make-up and break-out station is relatively low, and workers When making and unloading buckles, you have to bend over to work, and it is difficult to stretch the waist, resulting in high labor intensity for workers, reduced work efficiency, and easy to cause occupational diseases of low back pain

In addition, for the wellhead drill pipe sitting on the chuck when the drill pipe is screwed, the pipe body under the female joint will be clamped by the cone, often at the clamping part (it happens to be the place where the thickened transition zone of the drill pipe disappears, that is, The stress concentration part) causes biting damage, the wall thickness of the biting damage point is reduced, corrosion is prone to occur, and corrosion cracks are initiated. Under the action of stress, the crack expands to form a puncture leak, resulting in the failure of the drill pipe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0027] Embodiment: According to the above structure and processing method, a 5-inch high-station structure drill pipe of G105 steel grade was processed, and tests were carried out in Jiangsu Oilfield. Reduce the labor intensity during buckle operation and improve the efficiency of drilling operation; use the pneumatic roller chuck together to prevent the clamping tool from biting the drill pipe when tripping out.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

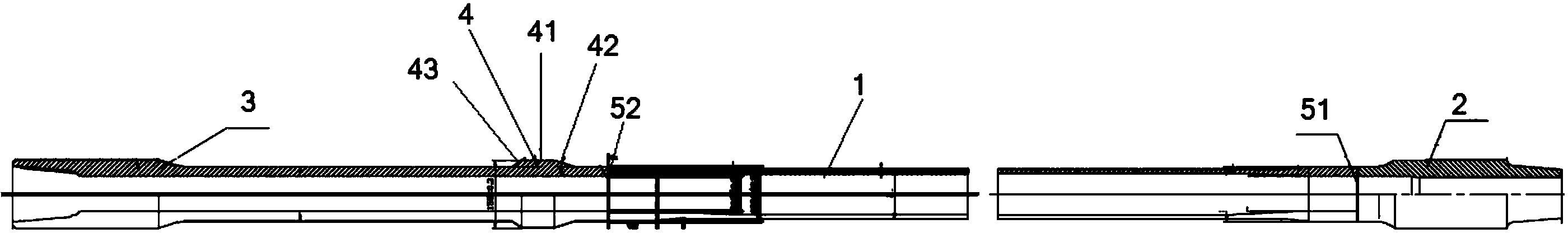

The invention relates to a drill rod structure with a high-station structure, and a manufacturing method. The drill rod structure comprises a drill rod pipe body, a male joint and a female joint; the female joint and the high-station structure are integrally processed, the high-station structure consists of a cylinder in the middle and transition cones at two sides, the taper of the two cones are respectively 18 degrees and 35 degrees; the ratio of the outer diameter of the cylinder in the middle of the high-station structure to the outer diameter of each drill rod joint is 85-95%. According to the drill rod structure, by changing the structure of a standard drill rod, the station, using a hydraulic power tong, of a drilling worker is ascended to the height adaptive to a human body when the drill rod is used for performing fastening and unfastening rotation-connecting operations at a well head, and the fastening and unfastening operation efficiency can be enhanced by improving the operation comfortableness; in addition, the meshing damage of an old type cone chuck to a pipe body in meshing and clamping can be eliminated by matching a pneumatic type cone-free slips for use.

Description

technical field [0001] The invention relates to a drill rod, in particular to a drill rod structure with a high station structure and a manufacturing method. Background technique [0002] Drill pipe is an essential tool for oil and gas drilling. The drill pipe is structurally divided into three parts: the drill pipe body, the male joint, and the female joint. The male and female joints are welded and connected to form a whole drill pipe. The drill pipes are screwed through the male and female joints to form a drill string. It mainly plays the role of torque transmission and drilling fluid circulation. The API series standards of the American Petroleum Institute are widely used in the world, so it is also called API drill pipe or standard drill pipe. The drill pipes currently manufactured and used at home and abroad (except for heavy drill pipes that play a transitional role and kelly pipes that apply torque) all adopt this structure. The actual drilling operation shows th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B17/00B23P15/00

Inventor 袁鹏斌董强周勇其程大刘甘露

Owner SHANGHAI HILONG DRILL PIPE MATERIALS INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com