Support type anchorage device capable of conveniently disassembling core and core material recovery method for support type anchorage device

A supportive and convenient technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of construction obstacles, waste materials, and difficulty in recycling of adjacent buildings, and achieve convenient recycling of core materials, simple recycling methods, Easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

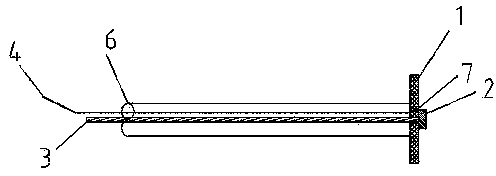

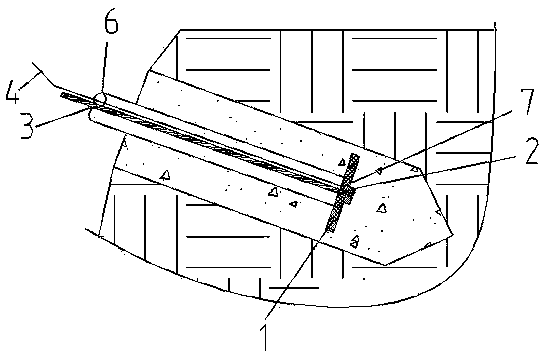

[0025] as attached Figure 1-3 Shown is the supporting anchorage that can be easily removed from the core according to the present invention, including an anchor plate 1, a support head 2, a wire 4, and an isolation sleeve 6; the anchor plate 1 is provided with an anchor hole 5; the support The head 2 is set under the anchor plate 1, and the outer diameter of the support head 2 is larger than the inner diameter of the anchor hole 5; when in use, the core material 3 passes through the anchor hole 5 and is fixed on the support head 2. When the core material 3 is pulled, The support head 2 can fix one end of the core material 3 on the anchor plate 1; the isolation sleeve 6 covers the core material 3 to isolate the core material 3 from the concrete on its outside; the isolation sleeve 6 can separate each Each core material 3 is individually wrapped, and multiple core materials 3 can also be wrapped together; the anchor plate 1 is provided with an electric heating device 7; the ele...

Embodiment 2

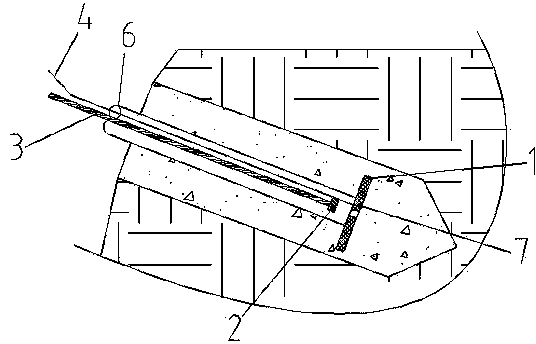

[0028] as attached Figure 4-6 Shown is the supporting anchorage that can be easily removed from the core according to the present invention, including an anchor plate 1, a support head 2, a wire 4, and an isolation sleeve 6; the anchor plate 1 is provided with an anchor hole 5; the support The head 2 is arranged below the anchor plate 1, and the outer diameter of the support head 2 is greater than the inner diameter of the anchor hole 5; the support head 2 includes a fixed rod 8 and a ring 9; the outer surface of the fixed rod 8 has a circle of concave holes. groove (not marked); during use, one end of the core material 3 passes through the anchor hole 5 and is fixed on the ring 9; the ring 9 is arranged in the outer groove of the fixing rod 2 to fix the core material 3 On the anchor plate 1, the isolation sleeve 6 covers the core material 3 to isolate the core material 3 from the concrete on its outside; the isolation sleeve 6 can wrap each core material 3 individually, or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com