A kind of gear shift assisting system for a vehicle

A power assist system, vehicle technology, applied in vehicle components, control devices, transportation and packaging, etc., can solve the problems of inability to realize power assist, heavy gear shifting, inflexible shifting manipulation, etc., and achieve quick response, easy implementation, and start-up flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

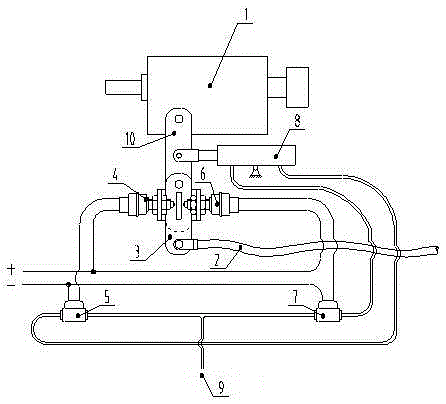

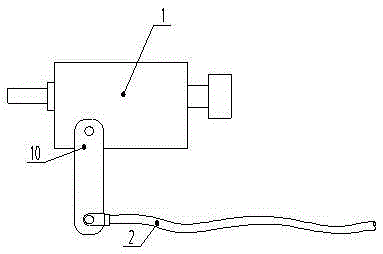

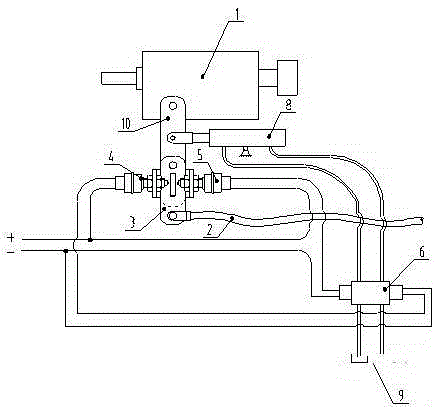

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. It includes a gearbox assembly 1, a shift rocker arm 10 and a shift cable (rod) assembly 2, and is characterized in that: the side of the shift rocker arm 10 is provided with a piston 8 fixed on the vehicle body, and the piston 8 is The piston rod is hinged on the shift rocker arm 10, and the contact switches for controlling the movement of the piston rod are arranged on both sides of the shift rocker arm 10. Under the effect of gear rod assembly 2, the deformed rocker 3 that starts the contact switch is far less than the force that drives the shifting rocker 10 to rotate, and the deformed rocker 3 can automatically reset when it is not stressed.

[0017] When implementing, for example figure 1 , the contact switch a4 and the contact switch b6 are respectively arranged at the two ends of the shifting rocker arm 10, if the vehicle is driven by gas, two electromagnetic gas valves are used, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com