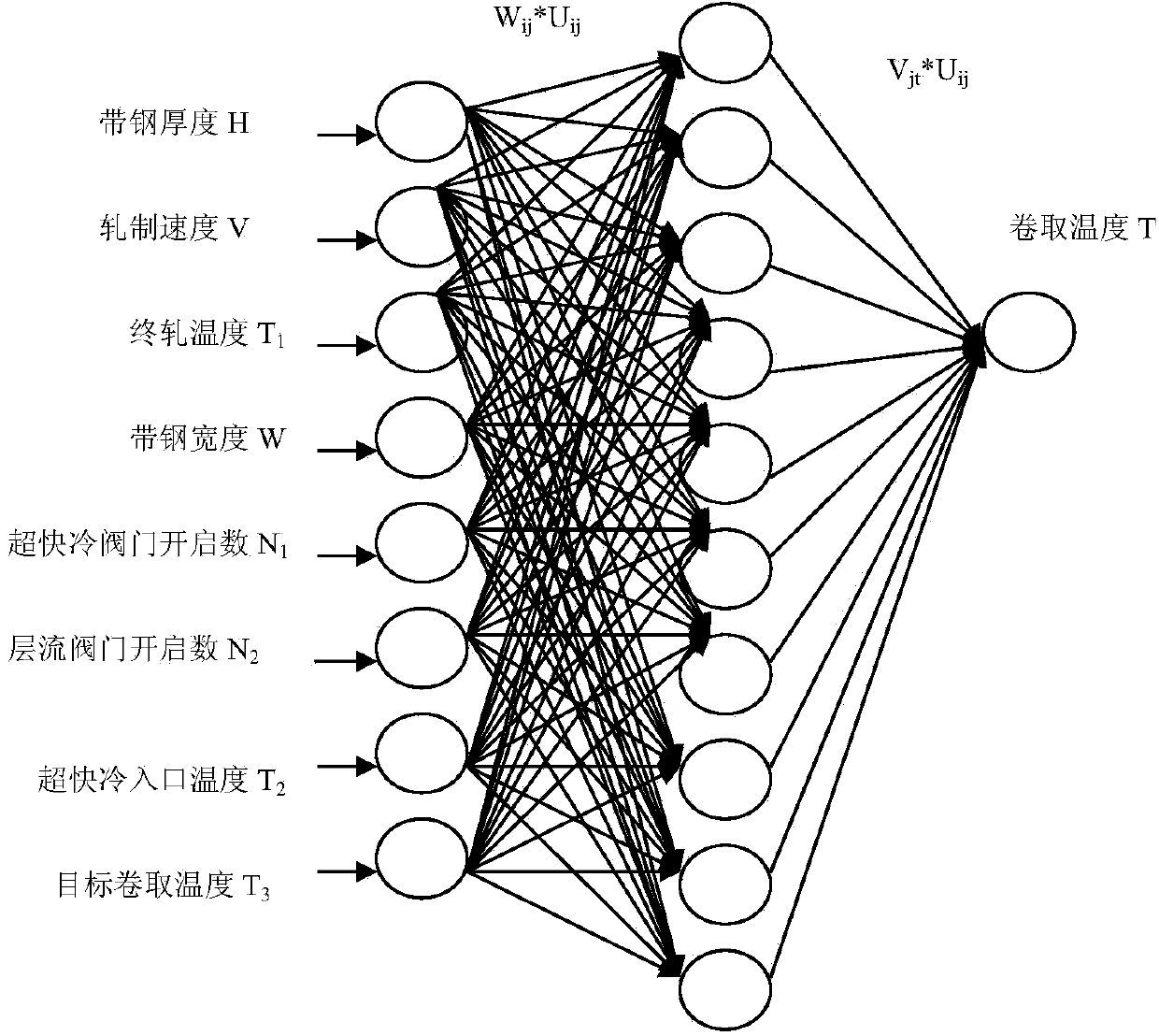

Hot-rolling coiling temperature forecasting method based on relevant neural network

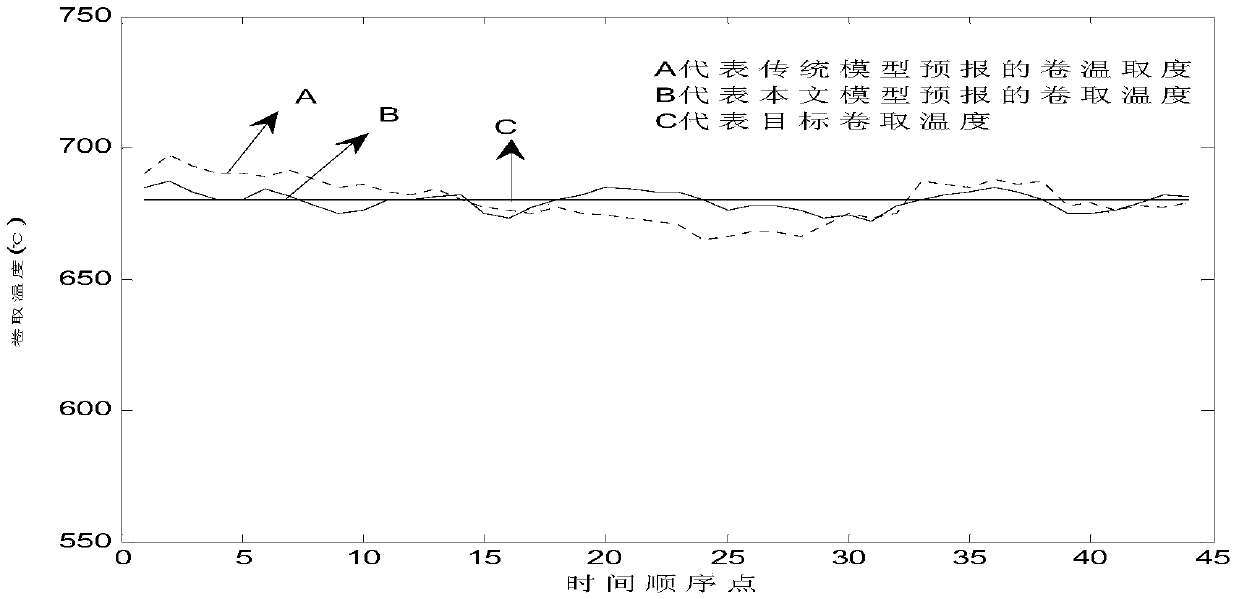

A neural network and coiling temperature technology, applied in the direction of temperature control, can solve the problem of inaccurate coiling temperature prediction and achieve accurate coiling temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

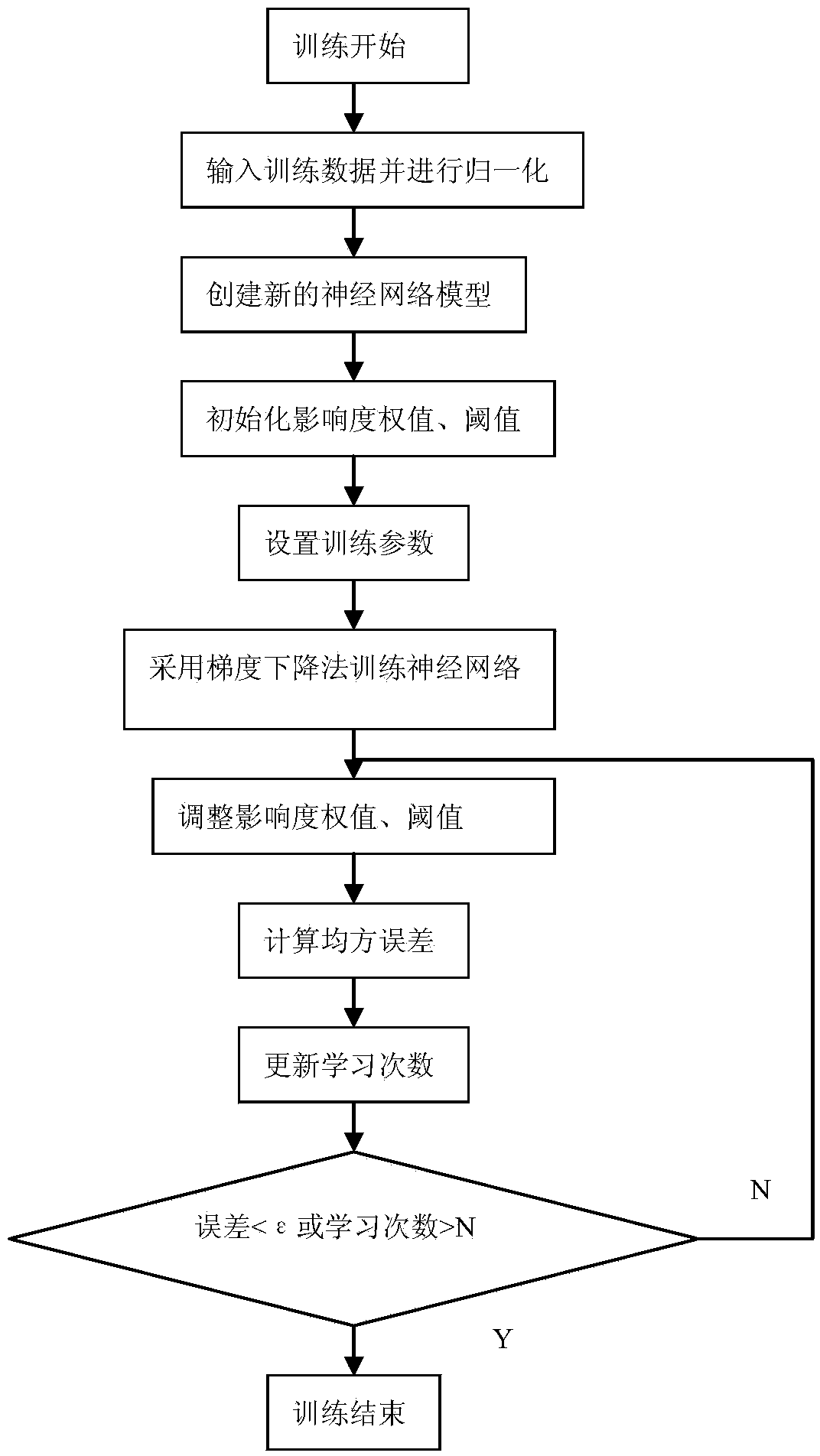

Method used

Image

Examples

Embodiment Construction

[0024] The controlled cooling part of the hot rolling mill is composed of ultra-fast cooling and laminar flow cooling. Electromagnetic flowmeter, after the flowmeter, there is an electric flow regulating valve, and each branch pipe is divided into two joints, which are connected to the hose nozzle box through the pneumatic regulating valve, and the distance between the nozzle box is 340mm. The accelerated cooling part is behind the ultra-fast cooling, which is composed of a water supply system, an air supply system and a control valve group. Water is supplied by a water tank. Each header is equipped with a flow meter and a regulating valve, which is convenient for individual adjustment. Afterwards, laminar flow nozzles and aerosol nozzles are installed at intervals. On the entire control cooling line, there are temperature detectors and corresponding sensors. The data during the steel rolling process is recorded in the PDA monitoring station, from which representative data are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com