Automatic paint spraying method of zipper heads

An automatic painting and zipper head technology, which is applied in the direction of pretreatment surface, coating, and surface coating liquid device, etc., can solve the problems of high labor intensity for operators, unsatisfactory product qualification rate, and difficult control of product quality, etc. , to achieve the effect of automatic operation, easy to ensure the painting effect and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

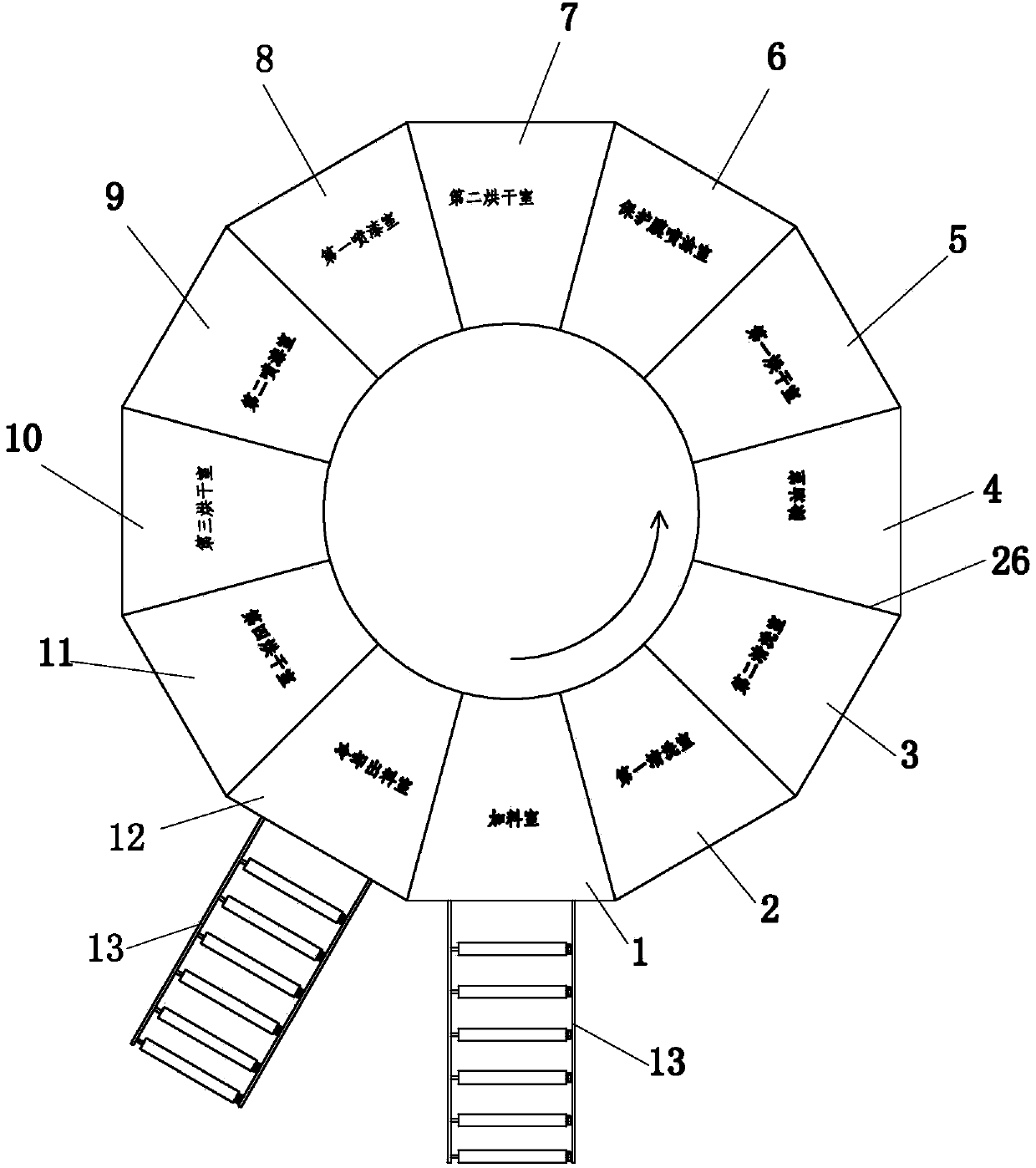

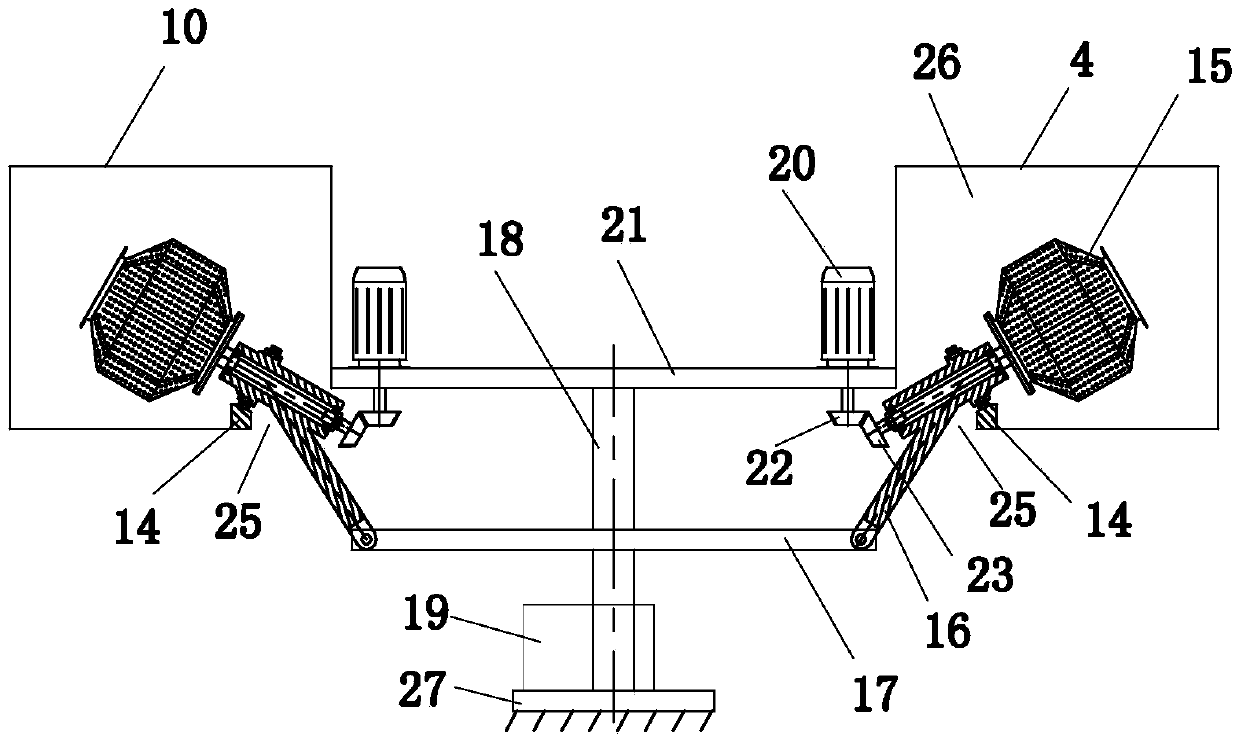

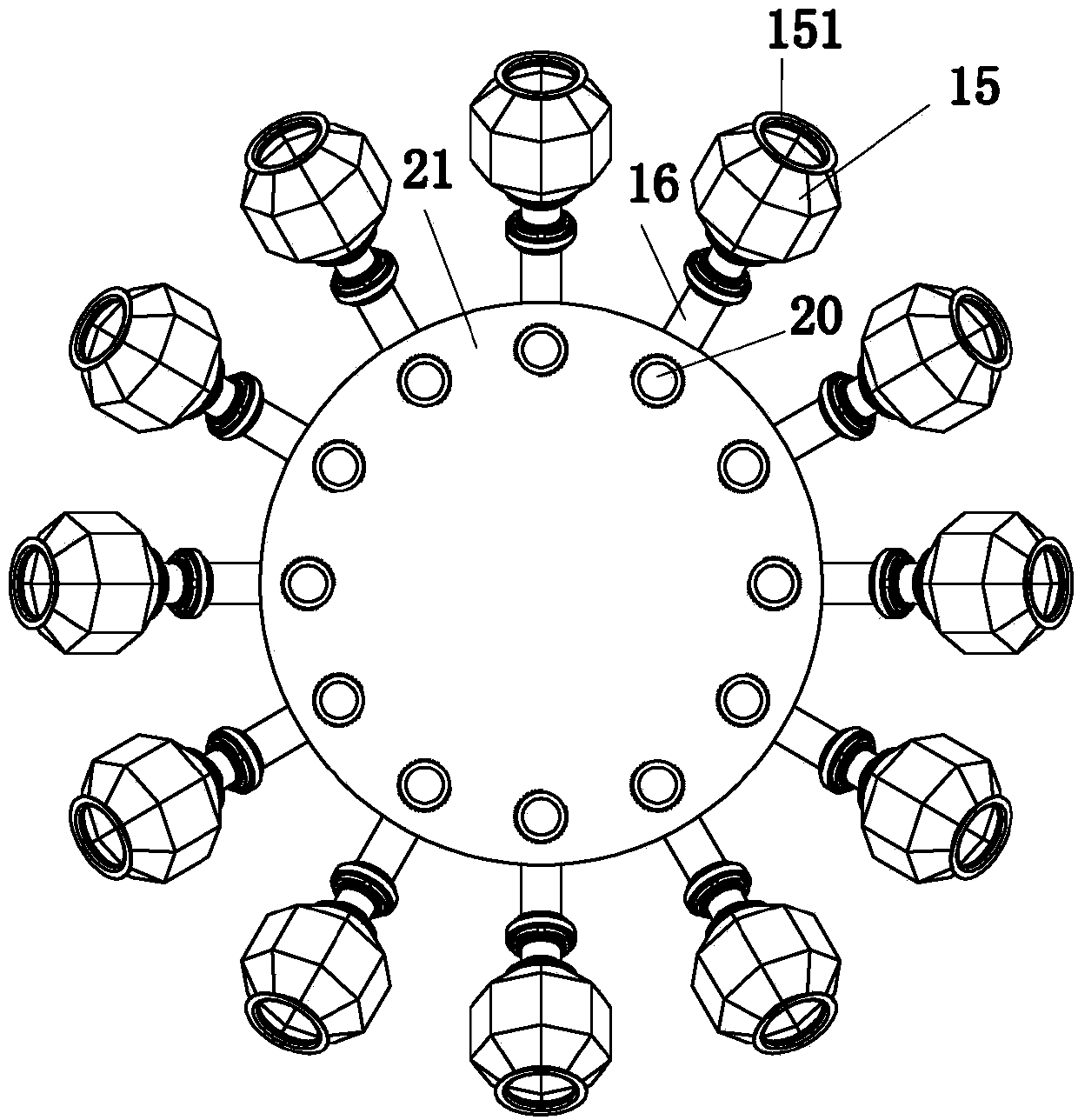

[0038] see Figure 1 to Figure 4 , an automatic painting method for zipper sliders, including feeding, cleaning, degreasing, first high-temperature drying, spraying film process, second high-temperature drying, painting, third high-temperature drying and cooling discharge carried out in sequence Process, each process is completed in a basically airtight workstation room, 12 workstation rooms of the same size are connected end to end to form a circular ring, according to the processing time of each process, one process occupies one or two workstation rooms , the station chambers of the first process and the last process are adjacent, and a circular track 14 is arranged in the station room, and the circular track 14 passes through each station room, and 12 circumferentially evenly distributed fixtures 15 pass through the supporting bracket 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com