Pulse-type drainage air filter

An air filter, pulsed technology, used in dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as difficult implementation and application, and achieve the effect of long service life, stable operation and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

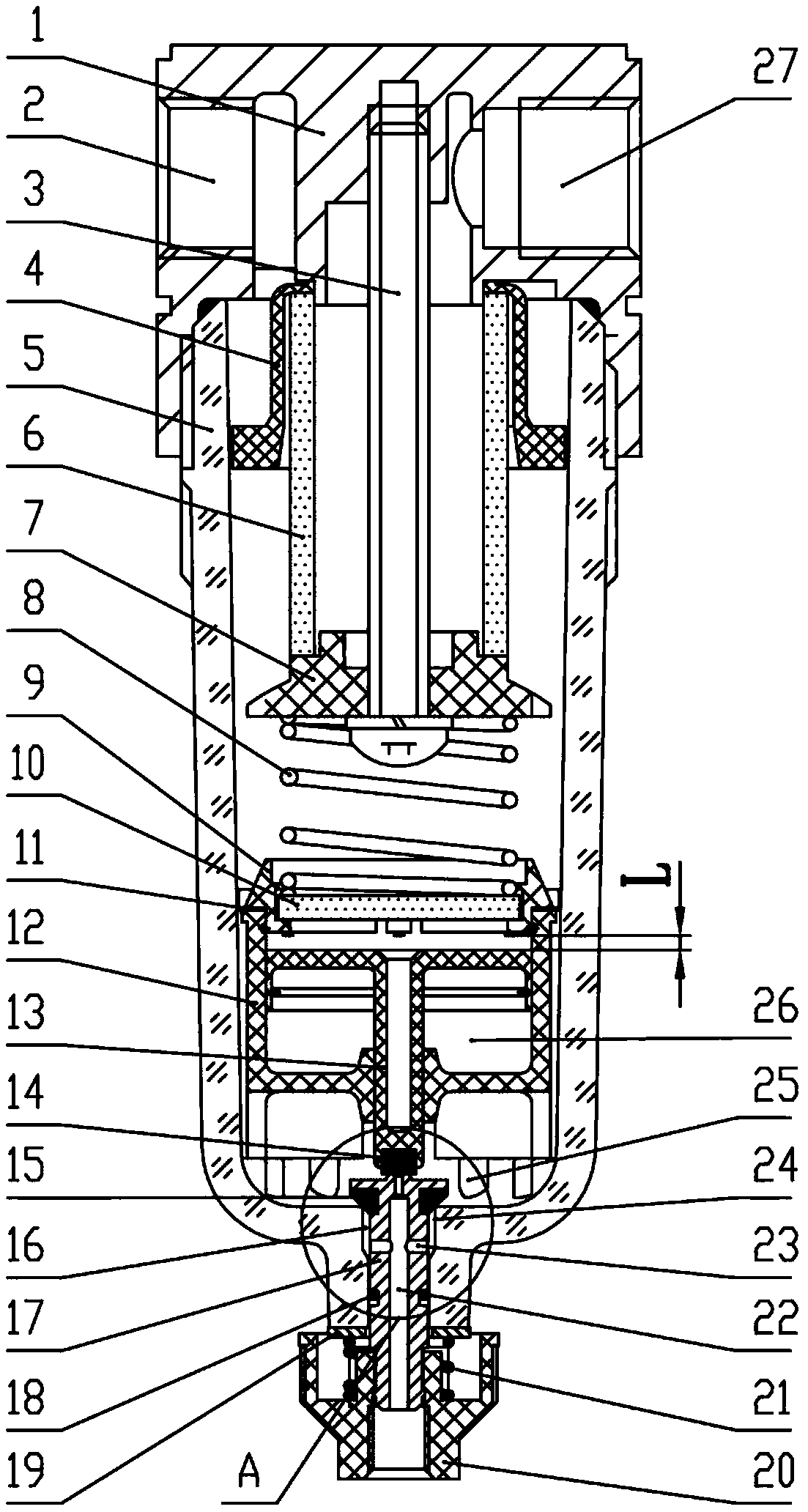

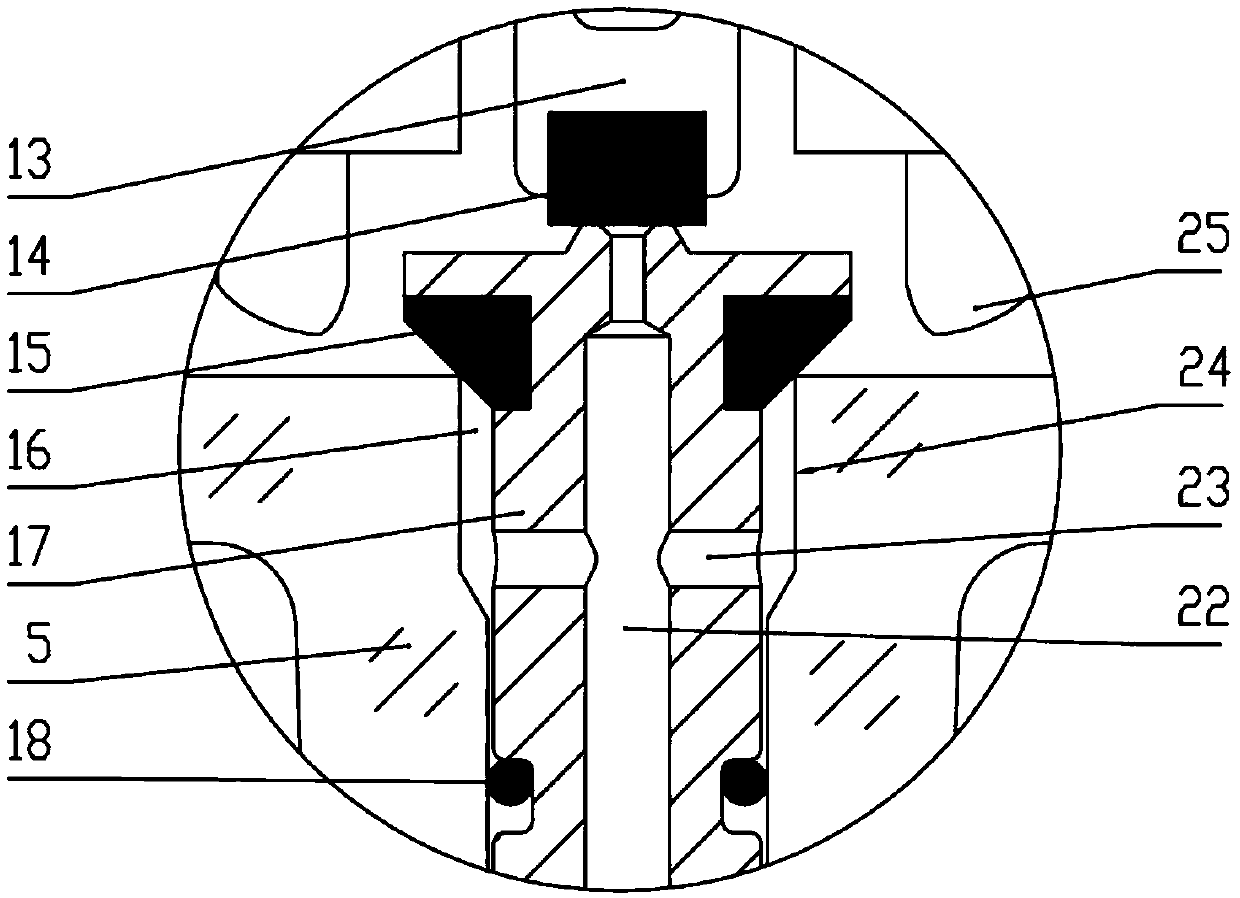

[0025] Examples, see Figure 1 to Figure 2 Shown: a pulse type drainage air filter, including a filter body 1 and a water cup 5 arranged on the filter body 1, the water cup 5 is tightly threaded with the filter body 1, and the filter body 1 is provided with an air source The inlet 2 and the air source outlet 27, the water cup 5 is provided with a filter assembly fixedly connected with the filter body 1, and the water cup 5 is provided with a pulse type drainage mechanism.

[0026] The filter assembly includes a cyclone blade 4, a filter element 6, a water retaining block 7 and a fixed rod 3, the water retaining block 7 is arranged at the lower end of the fixed rod 3, the upper end of the fixed rod 3 is fixedly connected to the filter body 1, and the filter element 6 passes through the water retaining block 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com