Conveying system, and use of a chamber extending inwardly with respect to a plastic module in a conveying system

A technology of conveying system and conveying direction, applied in the direction of conveyor, transportation and packaging, packaging, etc., can solve the problems of long logistics, disadvantage, long delivery time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

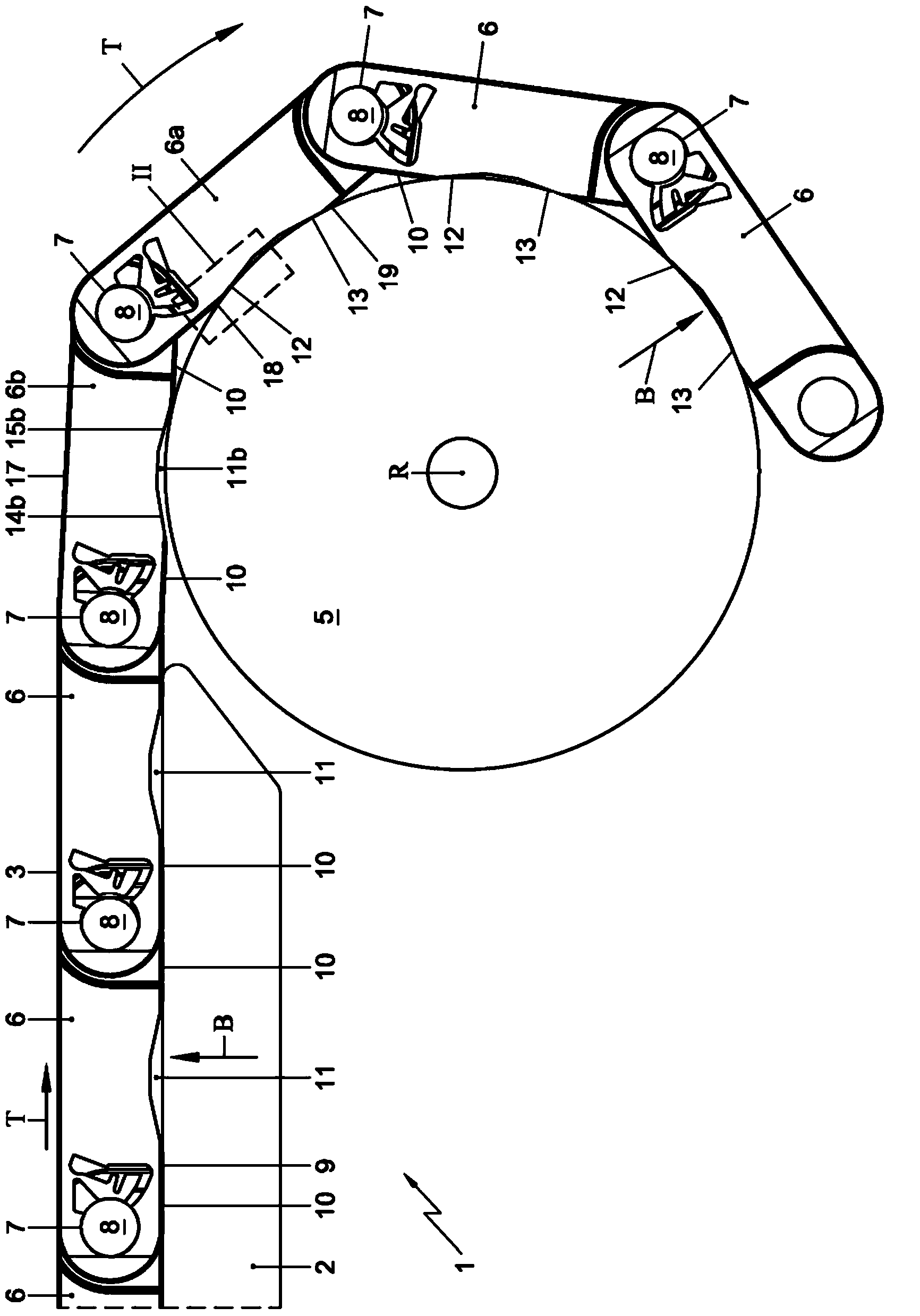

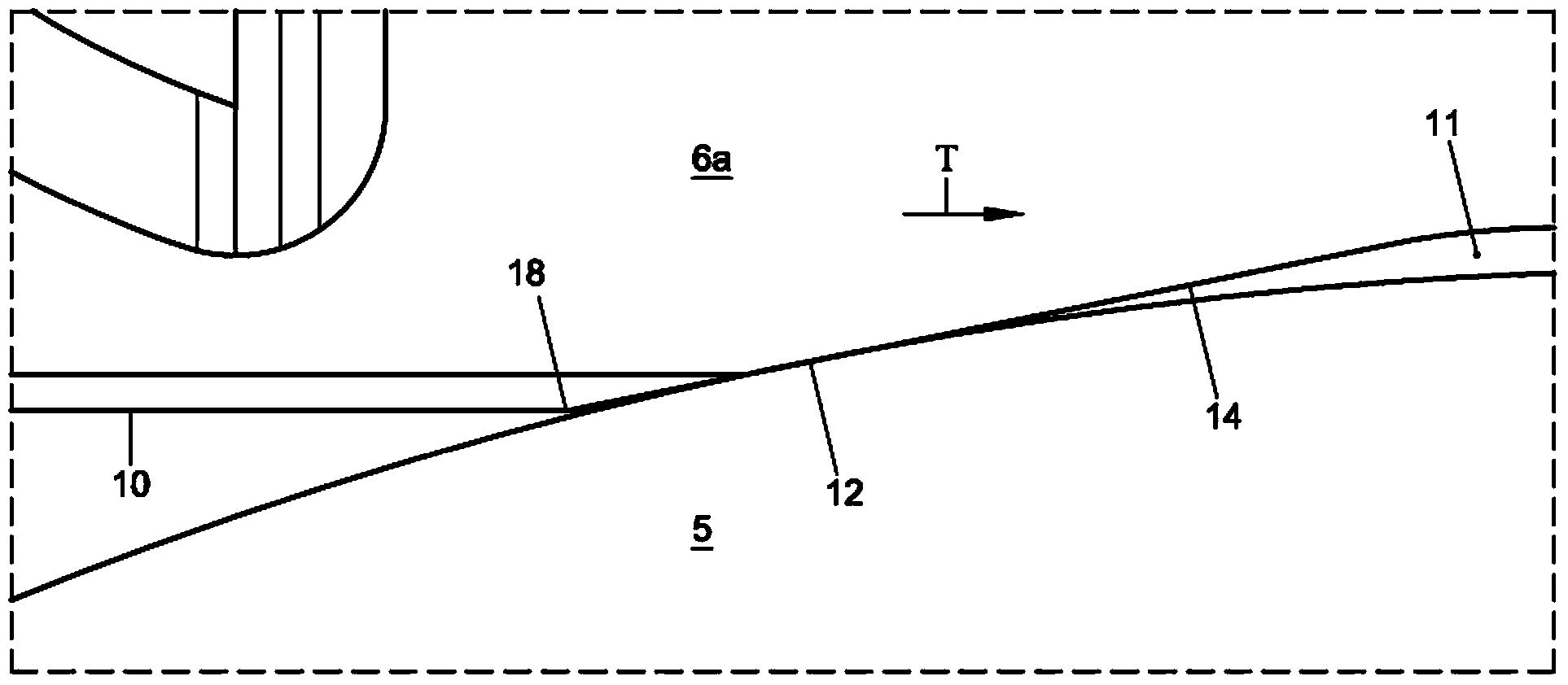

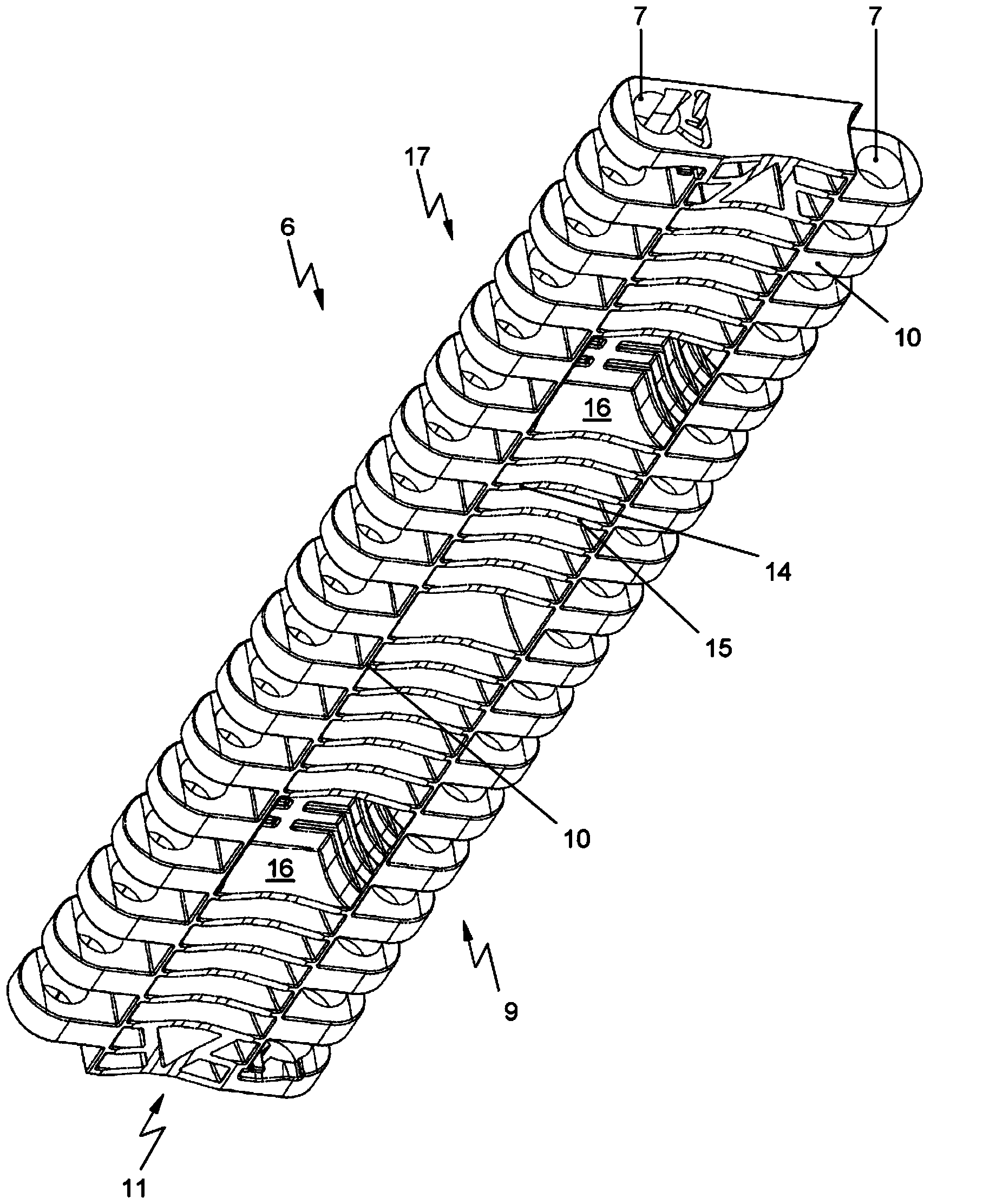

[0030] figure 1 A schematic cross-sectional view of part of a delivery system 1 according to the invention is shown. Said conveying system 1 comprises a conveying track 2, a continuous conveyor liner 3 intended to rotate around said conveying track 2 and suitable for conveying products in a conveying direction T, a drive (not shown) driving said conveyor liner 3 ), and a non-driven return guide 5 arranged on the conveyor track 2 for guiding the conveyor liner 3 during rotation, said non-driven return guide 5 being substantially transverse to the conveying direction T extend. The conveyor liner 3 comprises a plurality of plastic modules 6 which are continuous in the conveying direction T and extend transversely with respect to the conveying direction T, wherein each plastic module, viewed in the conveying direction T, has hinge loops on its front and rear sides 7. The hinge rings 7 of the successive modules 6 in the conveying direction T are connected and cooperate by means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com