Improved tread for heavy goods vehicle tyre

A technology for truck tires and treads, which is used in heavy-duty tires, heavy-duty vehicles, tire treads/tread patterns, etc., can solve problems such as reduced resistance to impact fragments, achieve good wear and driving performance, and improve wet road grip. The effect of ground performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

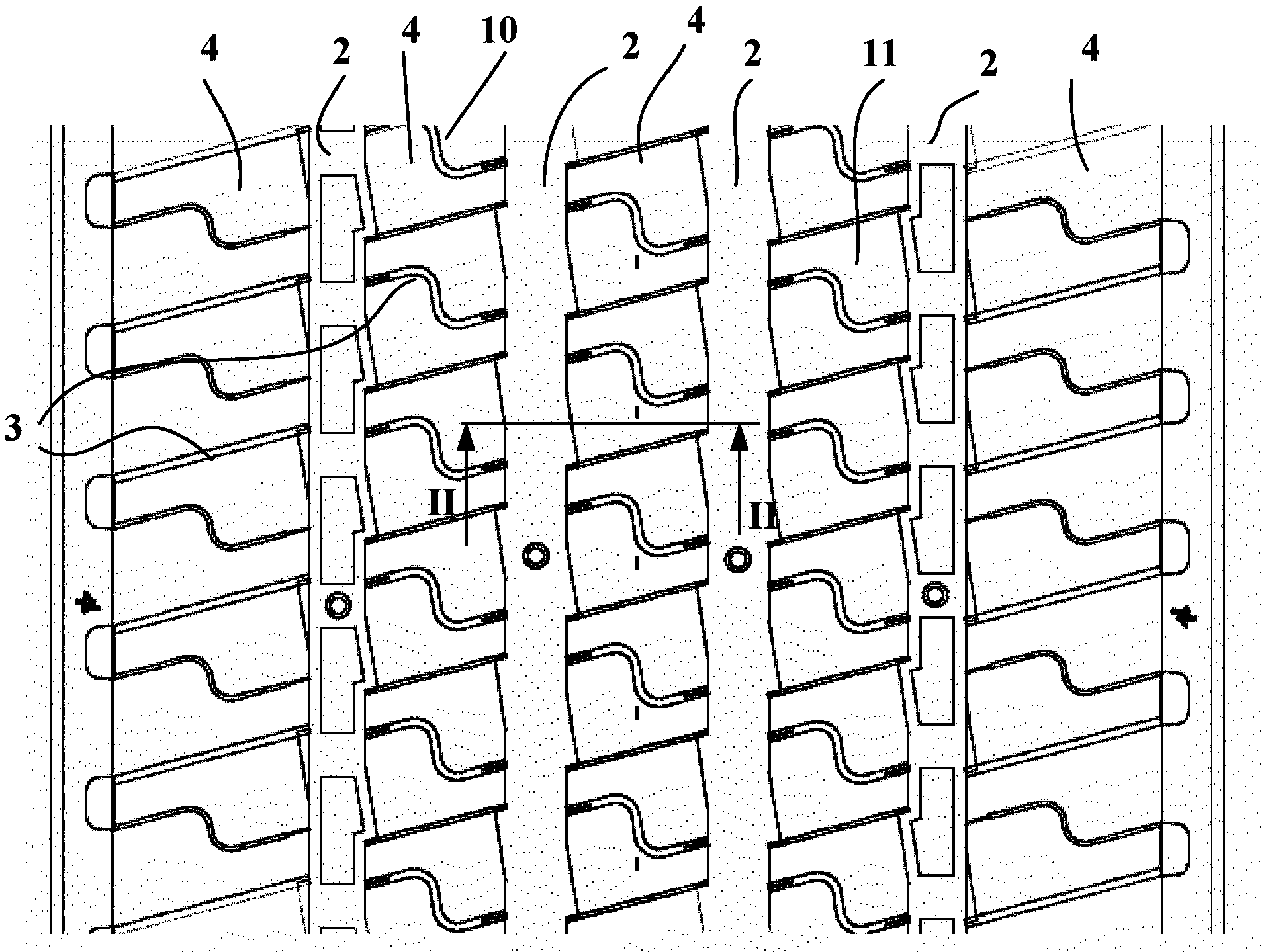

[0056] figure 1 A plan view of a tread 10 according to the prior art is shown corresponding to the commercially available tread pattern XZE2 of size 315 / 70R22.5.

[0057] The tread pattern design of this tread is denoted S0; hereinafter, this tread pattern S0 is considered as a reference tread pattern.

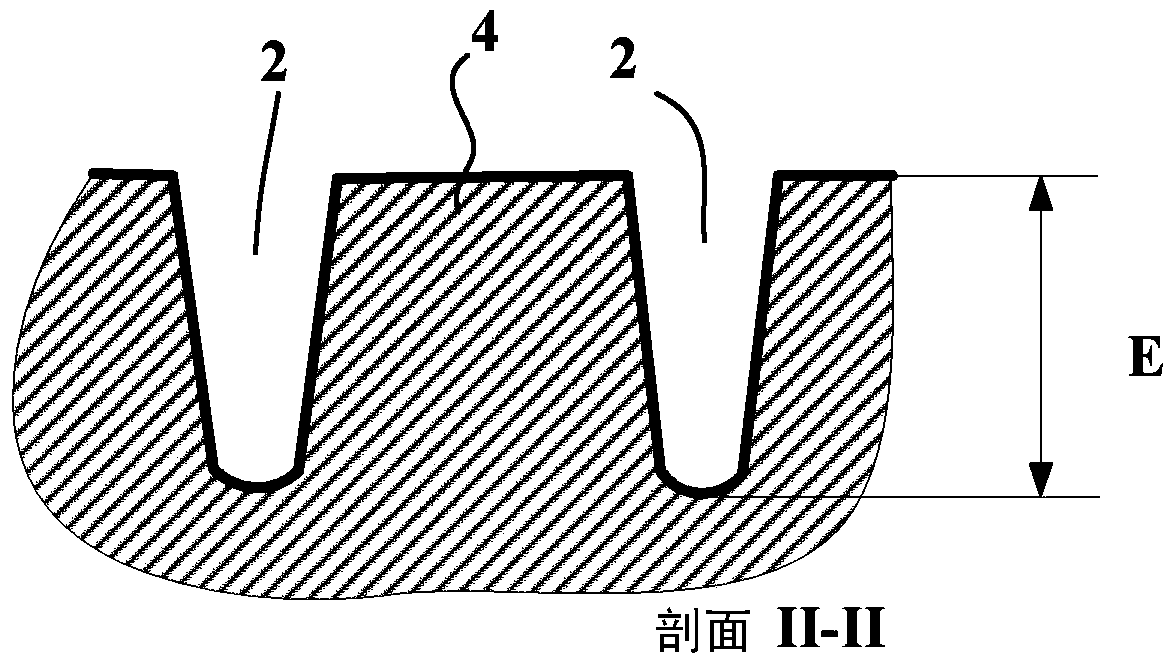

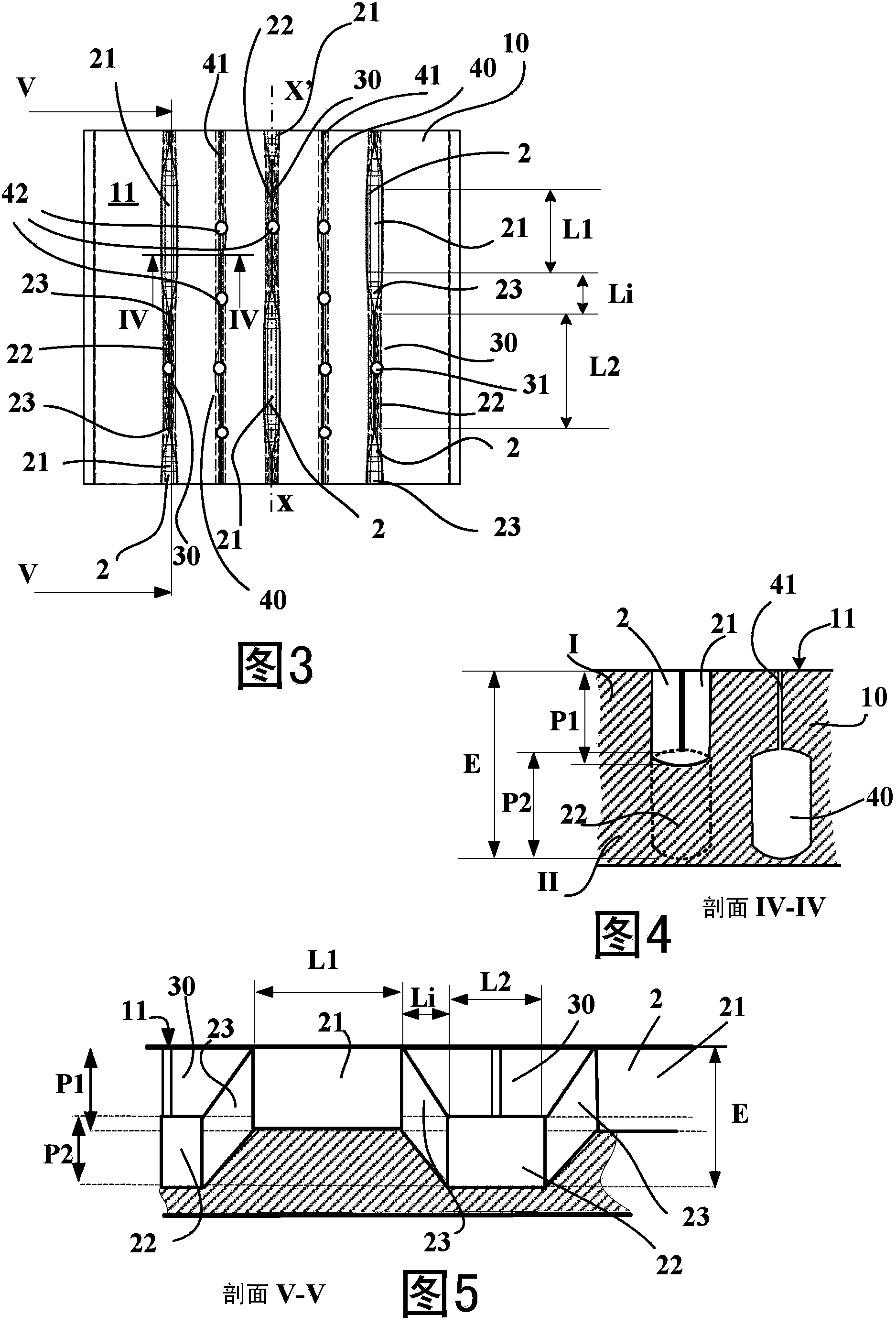

[0058] For the tire in question, this reference tread pattern S0 comprises four longitudinal grooves 2 of depth (equal to 15 mm) corresponding to the total thickness E of the tread intended to wear during running. The aforementioned reference tread pattern S0 also includes lateral grooves 3 having a narrow width and a shallow depth (at most equal to 2 mm). The longitudinal grooves delimit ribs 4 .

[0059] In an initial state corresponding to a new and unworn condition of the tread, this reference tread pattern S0 has a total void volume available in the contact block, measured at nominal inflation pressure and load conditions, which is greater and in this case is equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com