Parallel coordinate measuring machine controller

A measuring machine and controller technology, applied in the direction of digital control, electrical program control, etc., can solve the problems that cannot be used to control parallel coordinate measuring machines, poor dynamic response, large motion inertia, etc., and achieve the realization of handle follow-up measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

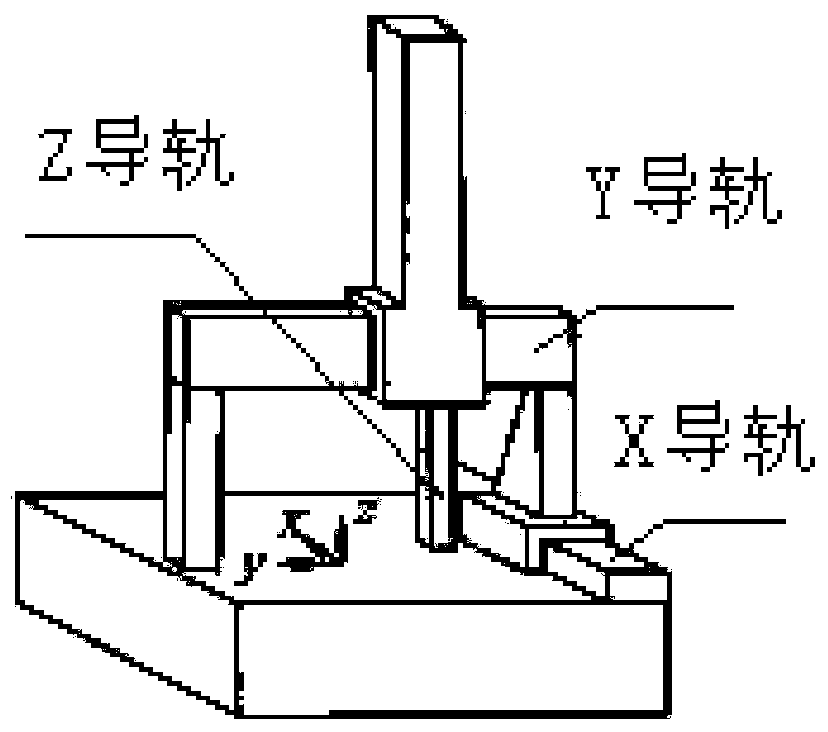

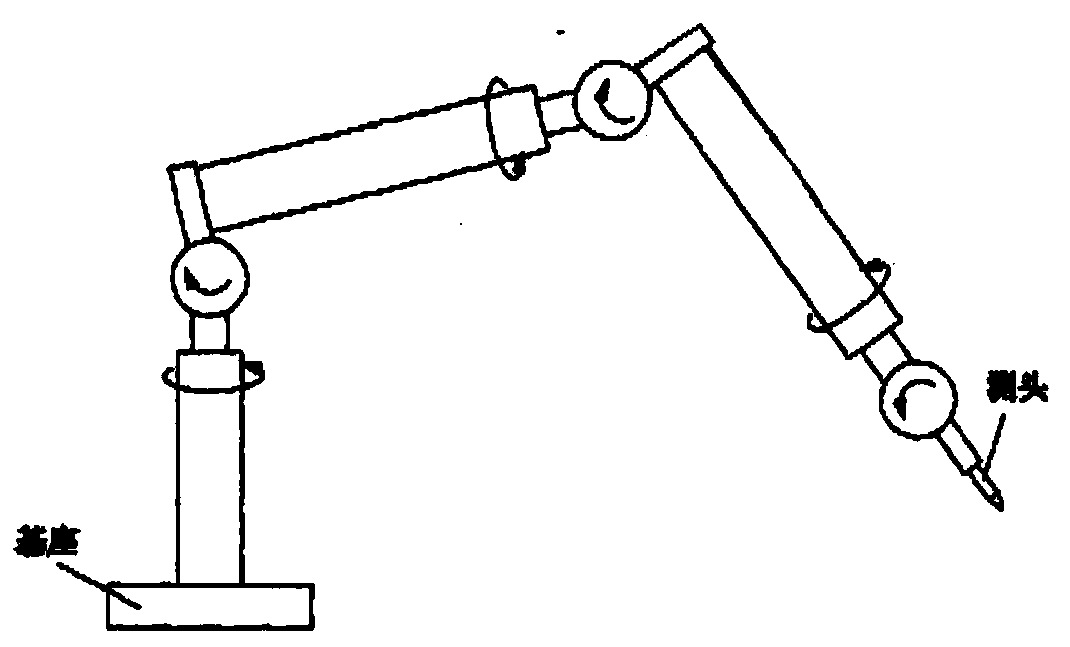

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

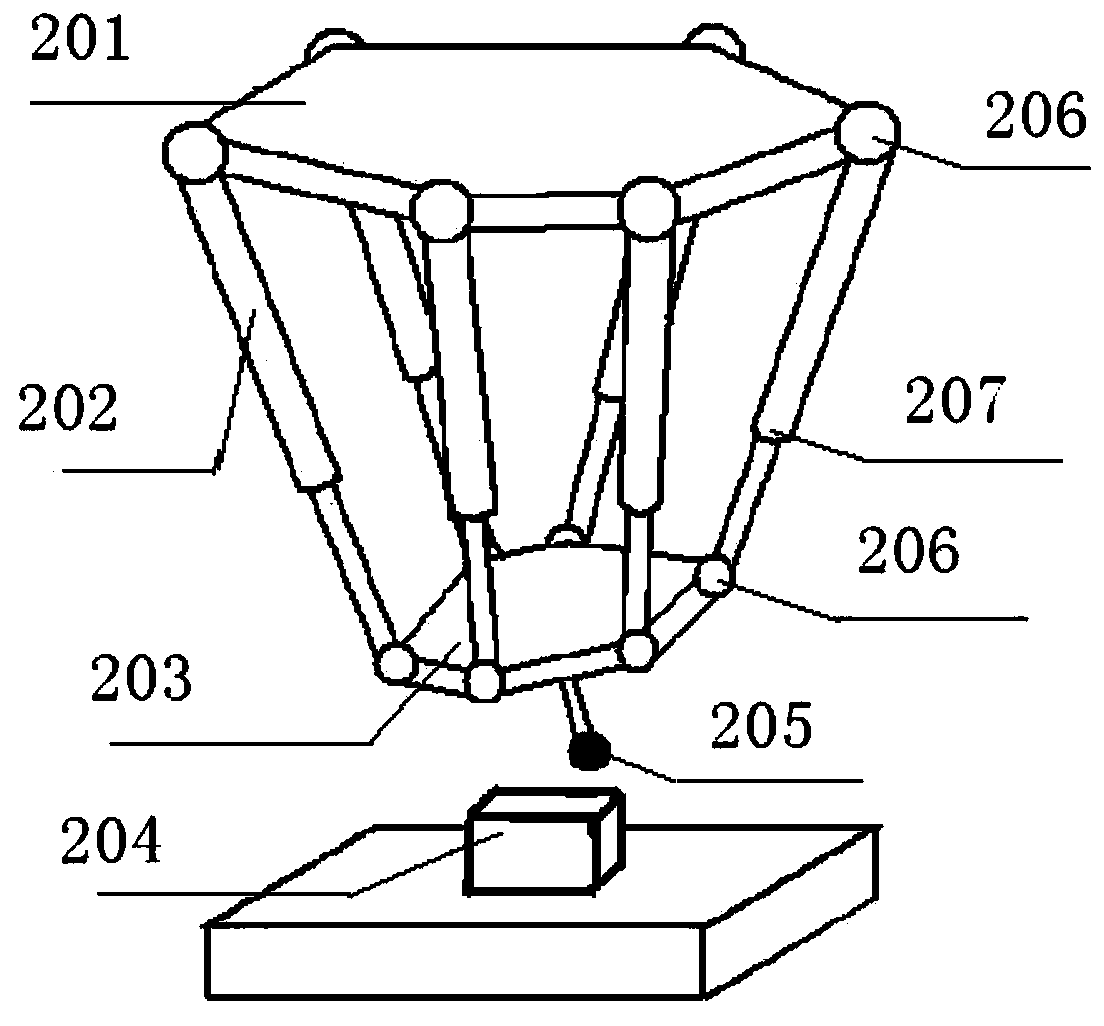

[0037] exist Figure 4 As shown in , the hardware of the parallel measuring machine controller of the present invention is mainly composed of Clipper motion control card, upper industrial computer, touch screen, interface card, handle, ACC-1P expansion card, DC servo driver, and chassis. The controller software of the parallel measuring machine is composed of the upper computer control software in the industrial computer and the lower computer control software in the Clipper motion control card.

[0038] The controller of this project adopts the open structure of the upper and lower computers, integrates 8 DC servo drivers, and is used to control the parallel measuring machine with 3 to 8 driving rods. It has zero return movement, automatic retraction movement of the measuring head, and handle follow-up control , programming automatic motion, self-learning motion control and other motion control functions; with digital logic control functions such as emergency stop, servo powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com