Macro fill light module with flexible circuit board

A technology for flexible circuit boards and circuit board components, which is applied in optics, instruments, photography, etc., and can solve problems such as affecting output efficiency, internal circuit breakers, and yield reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with accompanying drawings.

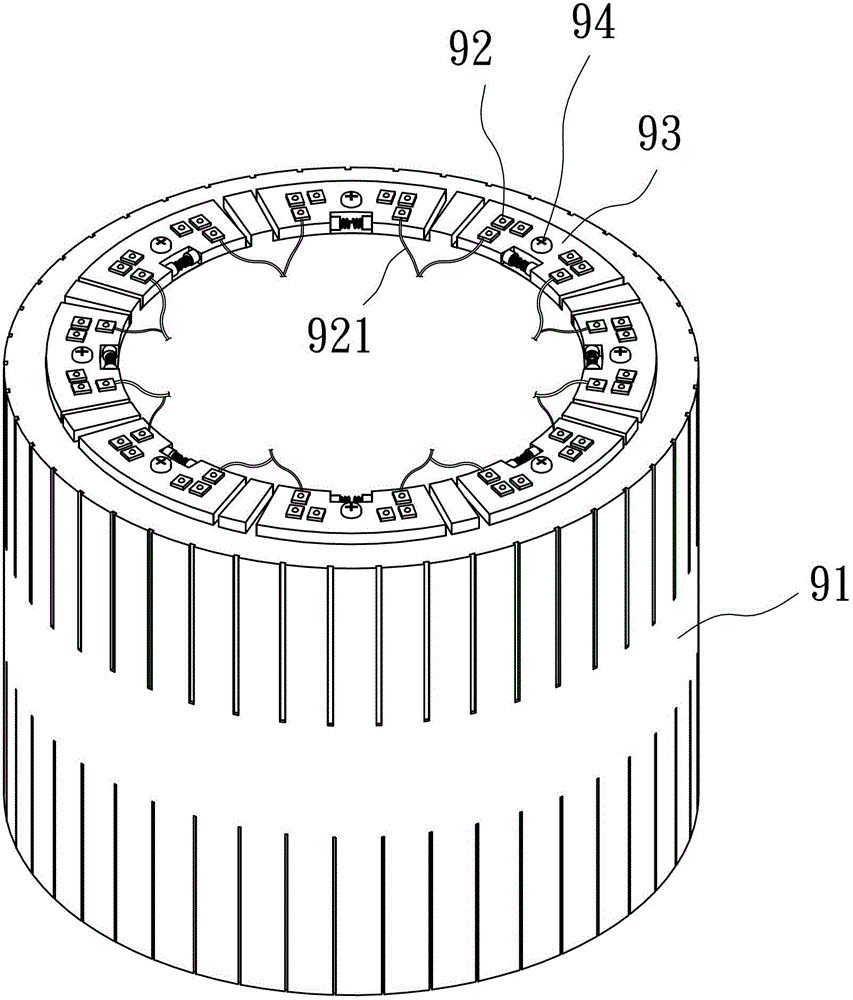

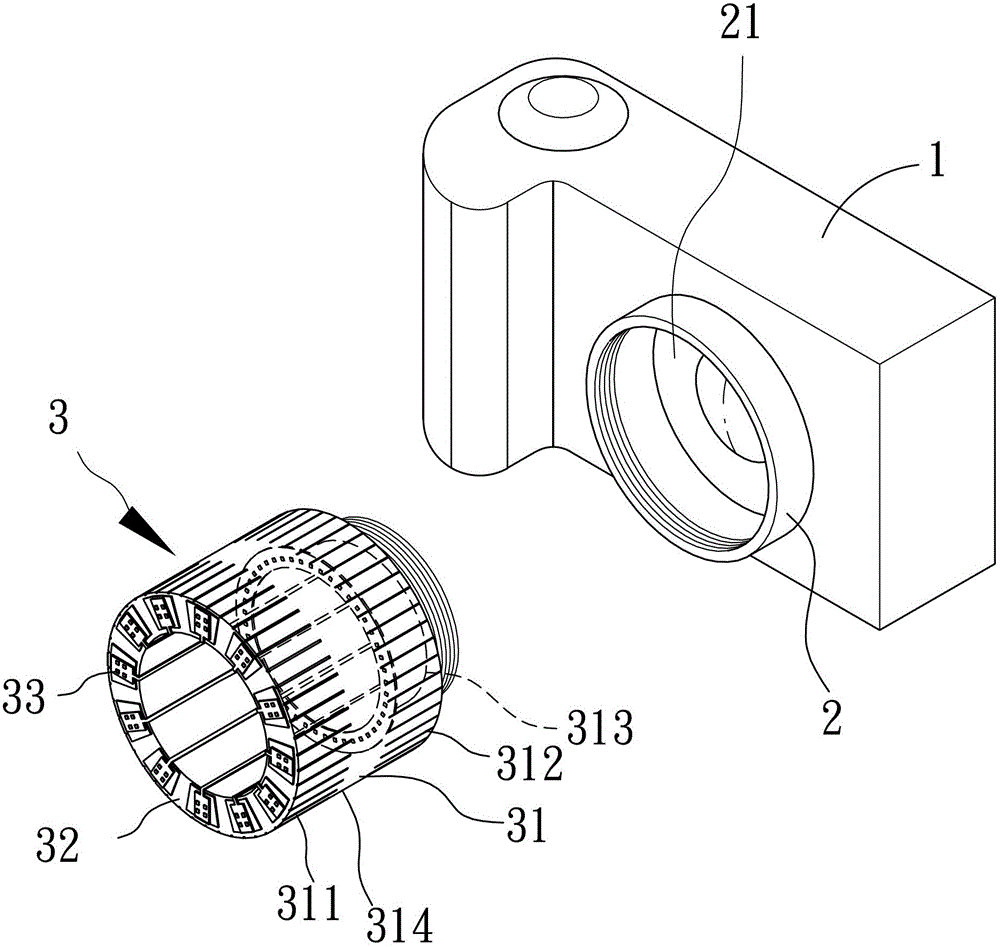

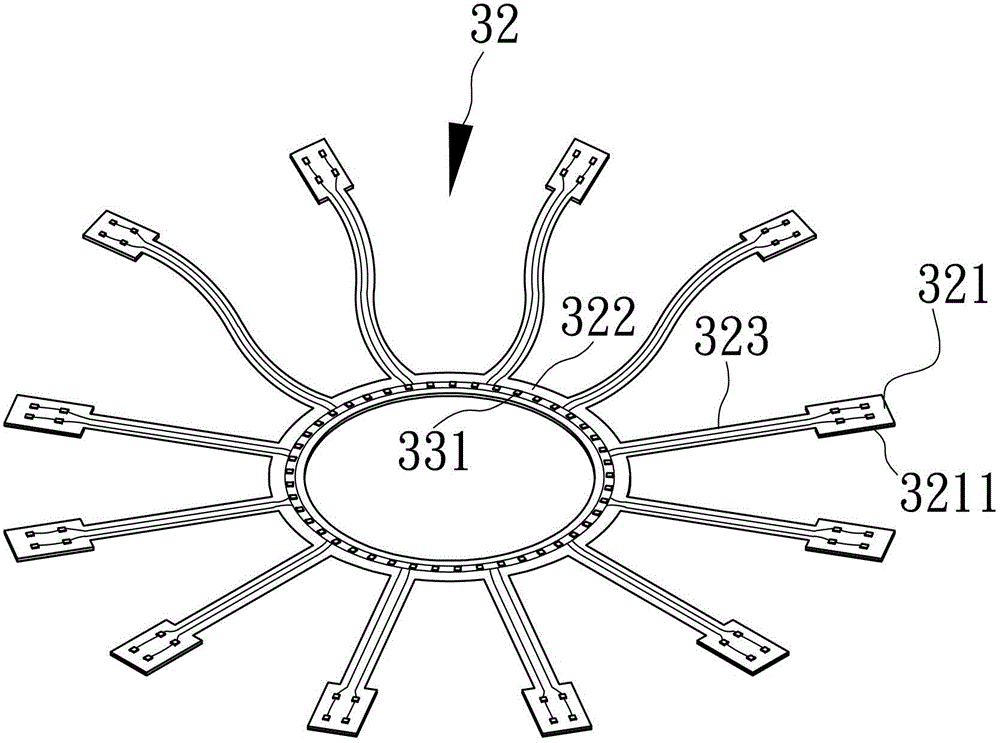

[0041] The first preferred embodiment of the present invention is Figure 2 to Figure 4 As shown, the optical image analysis device mainly includes a body 1, a lens 2 at the front end of the body 1, and a macro light supplement module 3 screwed on the lens 2. For the sake of illustration, the front of the lens 2 is defined here as The light entrance 21, all the image beams enter through the light entrance 21, therefore, the macro-distance supplementary light module 3 is screwed to the light entrance 21 correspondingly, and includes a sleeve 31, a circuit board assembly 32, a light emitting The component 33 and the angle adjustment component 34; in this embodiment, the optical image analysis device is illustrated as a single-eye camera, but it is not limited to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap