Lifting rod and illuminating lamp

A lifting rod and section rod technology, which is applied to lighting devices, lighting auxiliary devices, lighting and heating equipment, etc., can solve the problems of difficulty in controlling the relative rotation of the lifting section rod, and the irradiation direction of the lamp head is not fixed, and achieves a simple and reliable overall structure. Enhanced strength and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

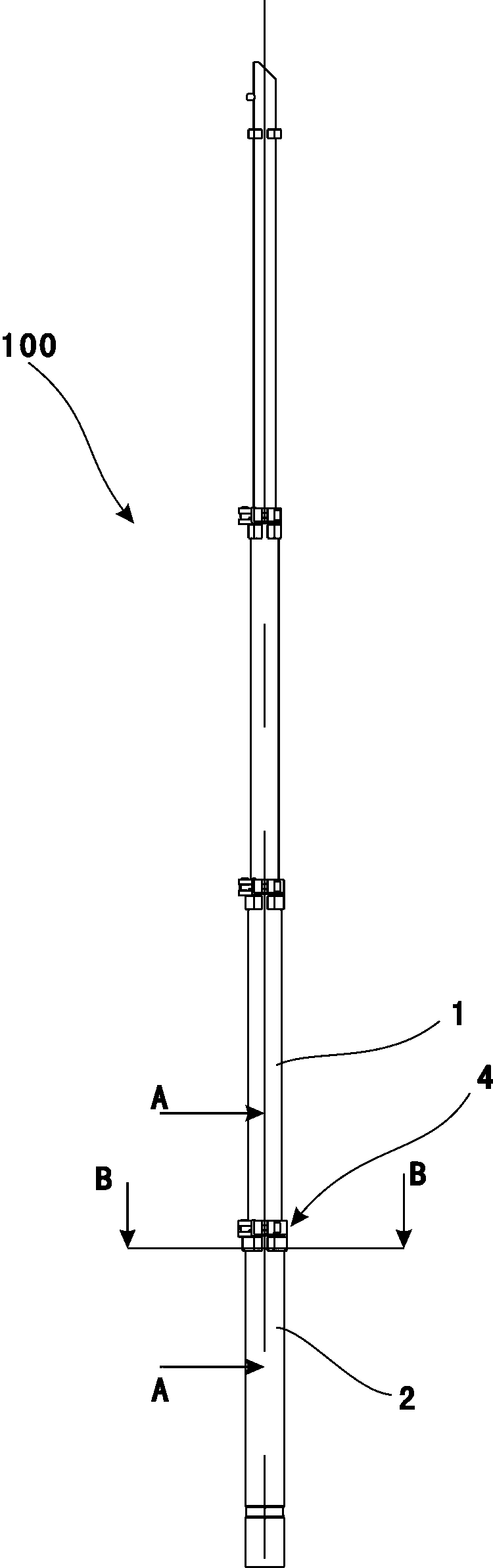

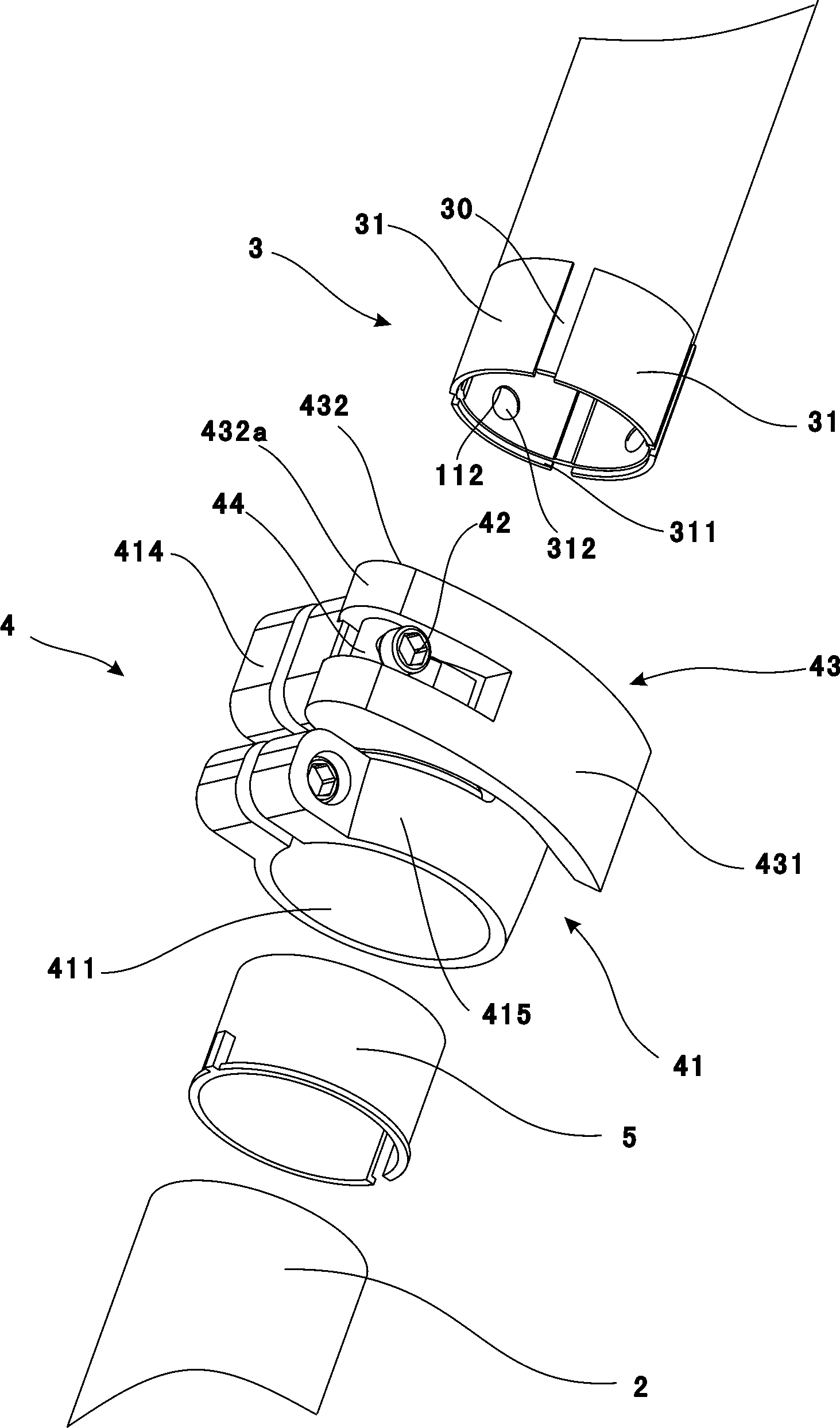

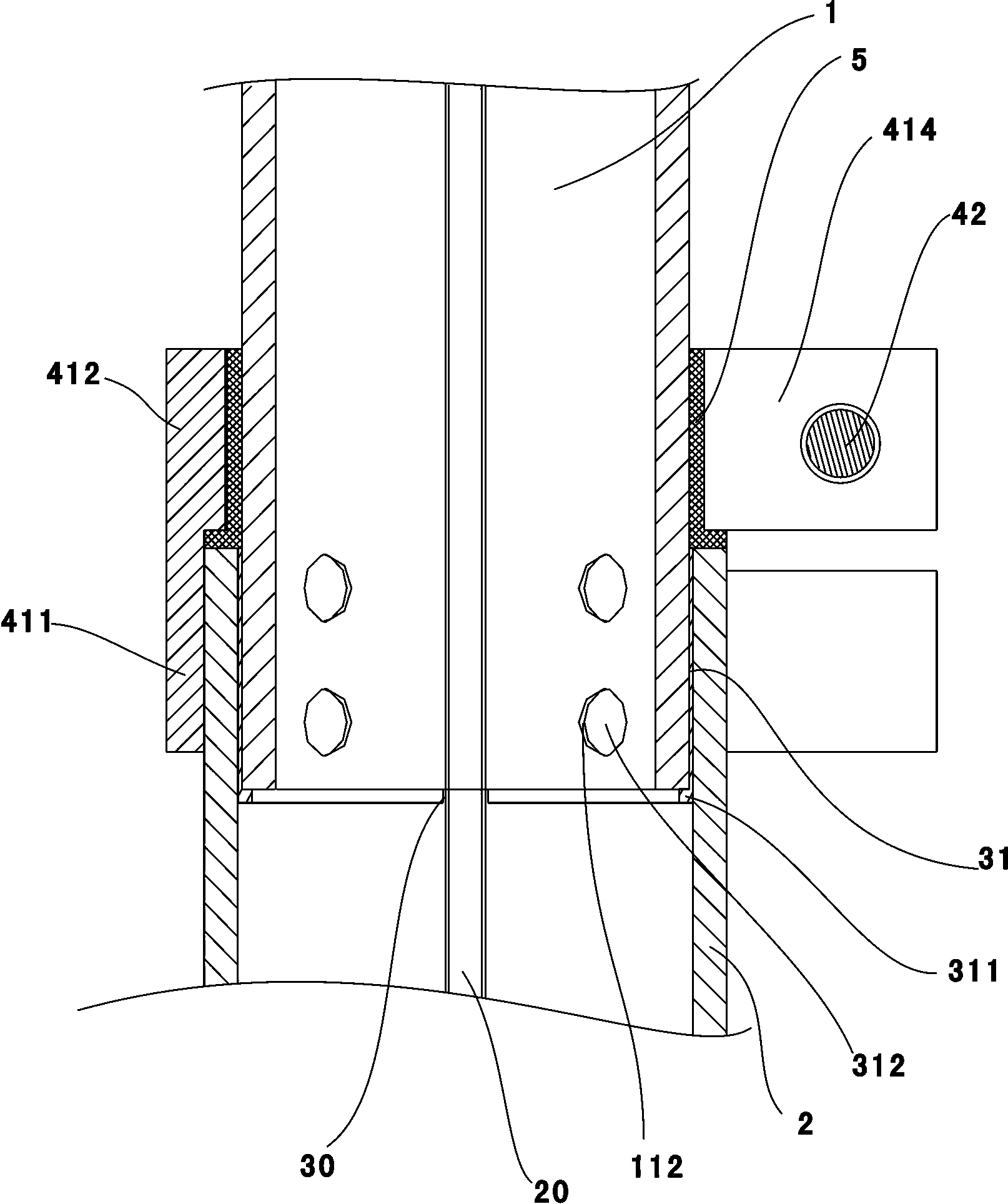

[0023] see figure 1 and figure 2 , a lighting fixture provided in an embodiment of the present invention includes a lifting rod 100 and a lighting lamp (not shown in the figure) connected to the lifting rod 100 . The lifting rod 100 includes at least two tubular lifting joints, a plastic bushing 3 and a locking mechanism 4 , which are sheathed in sequence from the inside to the outside, and the lighting lamp is fixed on the innermost lifting joint. The two adjacent lifting sub-rods in at least two lifting joints are respectively the inner joint 1 and the outer joint 2, such as Figure 2 to Figure 4 As shown, the plastic bushing 3 is fixed on the inner section bar 1 and is slidably arranged at one end of the outer section bar 2. The inner side wall of the outer section bar 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com