Guide sleeve used for positioning and fixing

A technology of guide sleeves and semicircular grooves, which is applied in the field of aerosol can gland positioning devices, can solve the problems of long travel of the gland, coaxial deviation between the can lid and the aerosol can, and drift of the can lid, achieving high reproducibility, Overcoming quality problems and good operability

Inactive Publication Date: 2013-12-18

彭山宏

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, capping machines at home and abroad often use an indexing mechanism with gap movement to drive the rotation of the star wheel shaft. Two sets of star wheels are fixed on the star wheel shaft. The lower star wheel set drives the aerosol can to rotate and feed, and the upper star wheel set drives the can. The cap is rotated and fed, and the capping action is performed at a certain station, so there are the following problems: 1. Due to the offset between the mouth of the aerosol can and the center of the bottom of the can, there is a coaxial deviation between the can lid and the aerosol can

2. The connection between the upper star wheel set and the star wheel shaft adopts key gap fit (to adapt to different tank heights and needs to move up and down), and is locked with bolts. It is difficult to coincide with the center and the axis and will shift during the locking process

3. Due to the light weight of the can lid, the shape of the can lid has a certain taper, and the capping stroke is long, there is a phenomenon that the can lid will drift during the capping process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

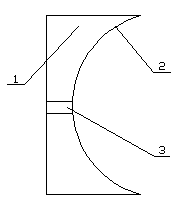

[0008] A guide sleeve for positioning and fixing, the guide sleeve 1 is installed at the front end of a telescopic mechanism, the guide sleeve 1 is an oily nylon cuboid with a semicircular groove 2, and a groove 3 is arranged in the middle of the semicircular groove 2 , the semicircular groove 2 of the guide sleeve 1 and the semicircular groove on the circumference of the gland star wheel form a concentric cylindrical hole.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a guide sleeve used for positioning and fixing. The guide sleeve which is a is an oil nylon cuboid with a semicircular groove is installed at the front end of an expansion mechanism; a groove is formed in the middle of the semicircular groove; the semicircular groove of the guide sleeve and a semicircular groove at the circumference of a star wheel of a pressure cover form a concentric cylindrical hole. The guide sleeve used for positioning and fixing has the beneficial effects of being high in recurrence precision and good in operability, overcoming quality problem of an aerial fog tank, ensuring coaxial positioning of the tank cover and an aerial fog agent tank, and therefore ensuring reliability and stability of the pressure cover.

Description

technical field [0001] The invention relates to a positioning device for the gland of an aerosol can, in particular to a guide sleeve for positioning and fixing. Background technique [0002] At present, capping machines at home and abroad often use an indexing mechanism with gap movement to drive the rotation of the star wheel shaft. Two sets of star wheels are fixed on the star wheel shaft. The lower star wheel set drives the aerosol can to rotate and feed, and the upper star wheel set drives the can. The cap is rotated and fed, and the capping action is performed at a certain station, so there are the following problems: 1. Due to the offset between the mouth of the aerosol can and the center of the bottom of the can, there is a coaxial deviation between the can lid and the aerosol can. 2. The connection between the upper star wheel set and the star wheel shaft adopts key gap fit (to adapt to different tank heights and needs to move up and down), and is locked with bolts....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B67B3/00

Inventor 彭山宏

Owner 彭山宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com