Bottom powder curing device of combined drying tunnel

A curing device and combined technology, which is applied in the direction of surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of reduced production efficiency, cumbersome operation, and adverse effects on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

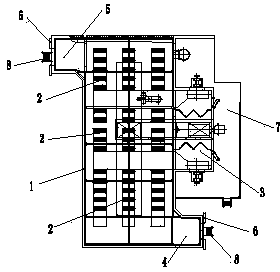

[0012] Combine below figure 1 Specific description embodiment:

[0013] A bottom powder curing device of a combined drying tunnel, characterized in that, the bottom powder curing device of the combined drying tunnel includes a housing 1, and the housing 1 is provided with several curing drying tunnel chambers 2, A curing oven heating chamber 3 that can heat the curing oven chamber body 2 is provided in the housing 1 on the side of the curing oven chamber body 2, and an inlet 4 is provided at one end of the housing 1, The other end of the housing 1 is provided with an outlet 5, and the entrance 4 and the outlet 5 are provided with a moving door 6 for a curing oven.

[0014] In a preferred manner, the casing 1 is provided with an inspection platform 7 .

[0015] Preferably, a ladder 8 is provided at the entrance 4 and the exit 5 .

[0016] In the base powder curing device of the combined drying tunnel provided by the present invention, when in use, the sprayed objects enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com