Device for measuring railway vehicle end relation

A technology of car-end relationship and rail vehicle, applied in the field of devices for measuring the relationship between rail vehicles Flexible and convenient, meet the requirements of stiffness test, and easy to adjust the installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

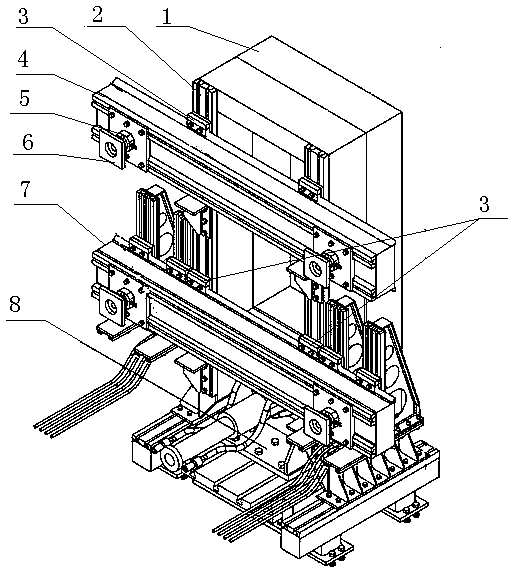

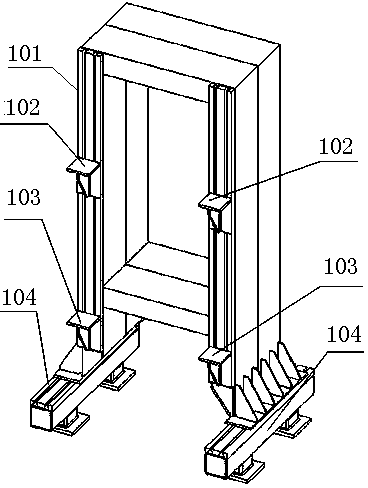

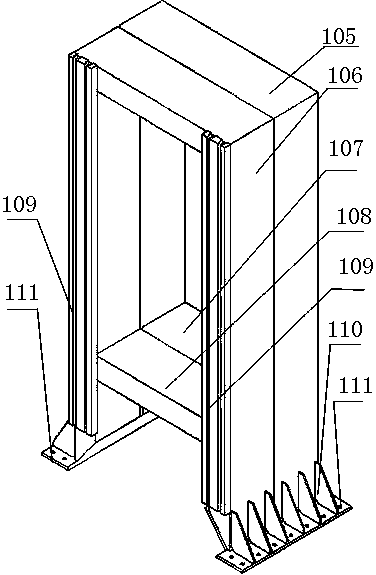

[0031] refer to figure 1 , the device for measuring the relationship between the vehicle end in the embodiment of the present invention is composed of the upper door frame dovetail guide rail beam device 4, the lower door frame dovetail guide rail beam device 7, the coupler reaction force hinge seat assembly 8 and the vehicle end wall fixing device 1, The upper door frame dovetail guide rail beam device is adjustable up and down connected with the T-slot guide rail 2 in front of the vehicle end wall fixing device 1 through the bead assembly 3, and the lower door frame dovetail guide rail beam device is also fixed with the vehicle end wall through the bead assembly 3 The T-slot guide rails 2 in front of the device are adjustable up and down, and the whole device is arranged in pairs, and the three-dimensional force sensor 5 on the front side of the upper door frame dovetail guide rail beam device and the lower door frame dovetail guide rail beam device is connected to the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com