Complex surface workpiece positioning method based on particle swarm optimization

A technology of particle swarm algorithm and positioning method, which is applied in the field of workpiece positioning on complex curved surfaces, can solve the problems of poor positioning accuracy and achieve high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

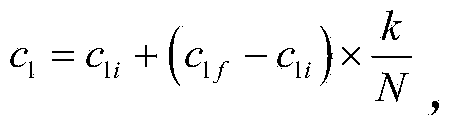

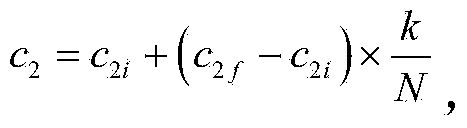

[0018] The specific steps of the complex curved surface workpiece positioning method based on the particle swarm algorithm in the present invention are as follows:

[0019] Step 1. Clamp the blade blank on the CNC machine tool workbench in any orientation, set the machining coordinate system at any position in the machine tool coordinate system, and use the online detection device to obtain several blank surface measurement points Q along the isoparameter line i .

[0020] Step 2. Importing the obtained surface measurement points of each blank into the CAM system programming coordinate system where the theoretical model of the blade part is located according to its coordinates in the machining coordinate system.

[0021] Step 3. Use a rough positioning method in the CAM system to measure point Q on the surface of the blank i Pre-registration is performed with the surface P of the theoretical model of the part, so that the relative positions of the two are relatively close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com