Downhole pneumatic shock wave generator

A generator and shock wave technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of reduced working life, incomplete function, accelerated shock wave generator damage, etc., to improve efficiency and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. The following content is a further detailed description of the present invention in conjunction with specific preferred embodiments. It cannot be assumed that the specific implementation of the present invention is only limited to these descriptions. Those of ordinary skill in the technical field of the present invention can also make some simple deduction or replacement without departing from the concept of the present invention, and the above structures should all belong to the protection scope of the present invention.

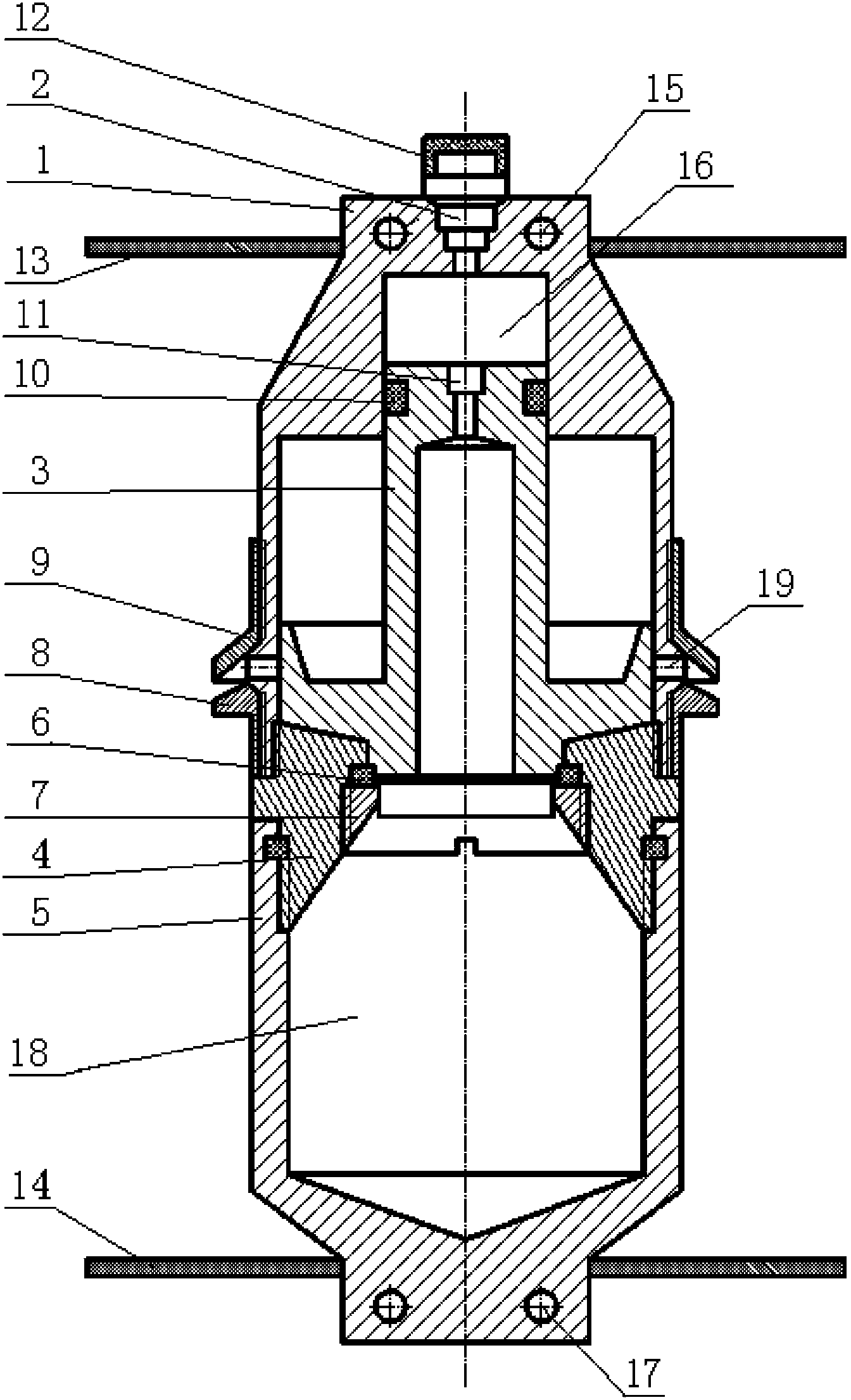

[0015] The overall structure of the pneumatic shock wave generator provided in this embodiment is as follows: figure 1 As shown, at least the generator body is included. The upper and lower parts of the generator body are respectively provided with an upper shock wave reflection device 13 and a lower shock wave reflection device 14. The upper shock w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com