Filter device and filter extruder head containing the same

A filter device and extruder head technology, which is applied in the field of filter devices, can solve the problems of equipment not working properly, labor-intensive, time-consuming, and low production efficiency, and achieve simple and easy waste removal, long service life and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 7 :

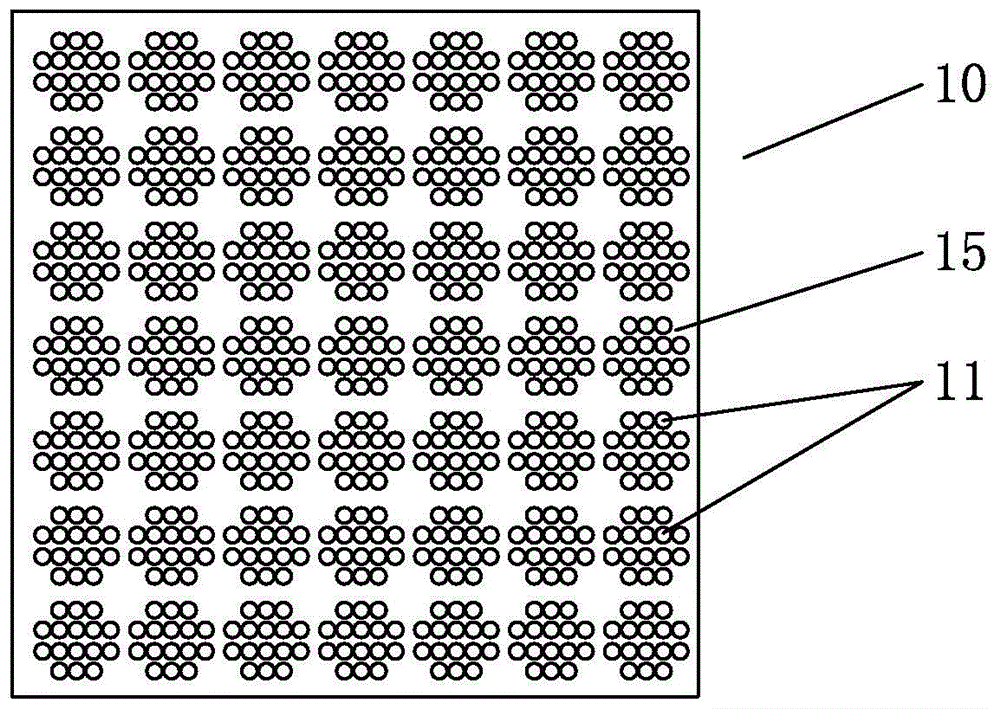

[0030] The filter device 01 is formed with several filter groups 15 evenly distributed on the substrate to form a filter screen 10, each filter group 15 is arranged at intervals by several filter holes 11 or 12 and 13, and the outer contour of each filter group 15 is a geometric figure .

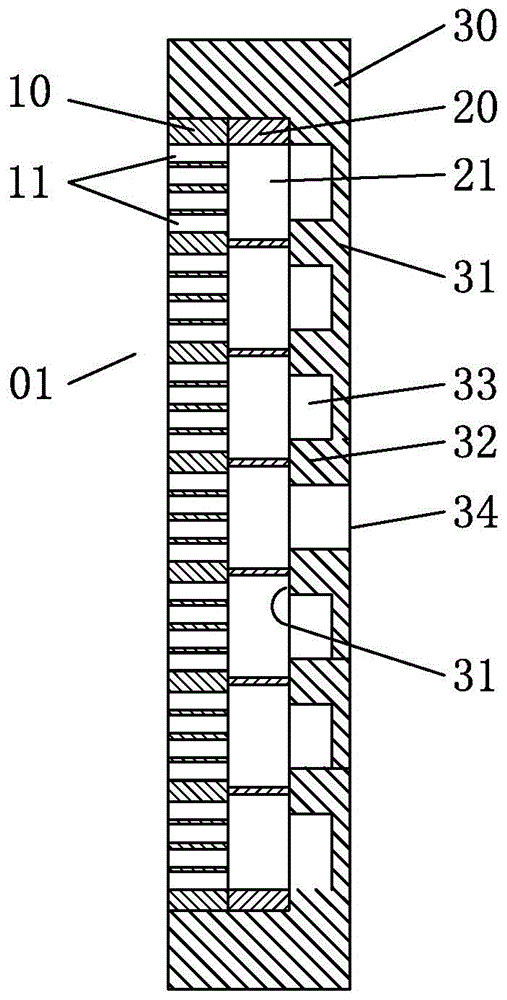

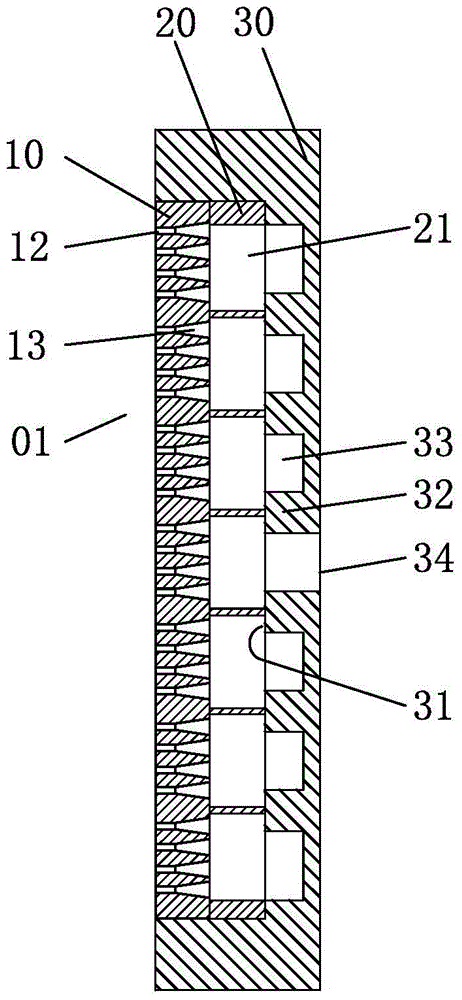

[0031] The bottom of the above-mentioned filter screen 10 is provided with a support discharge mechanism, and the specific structure of the support discharge mechanism is: the substrate is provided with several large through holes 21 corresponding to each of the filter groups 15 to form a reinforcement net 20, Each large through hole 21 corresponds to a filter group 15 and does not block all filter holes 11 or 12 and 13 on the filter group 15; or

[0032] The specific structure of the supporting discharge mechanism is: several suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com