Chemical binder for coating payload in open top hopper cars, trucks, piles and similar storage/shipping containers

An adhesive, rail car technology for application in the field of chemical adhesives for coating loads in open top hopper cars, trucks, buildings, similar storage units/containers, capable of addressing limitations Conditions of use and application etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The foregoing may be better understood with reference to the following embodiments, which are presented for illustrative purposes only and are not intended to limit the scope of the present invention.

[0043] The tailings from mineral processing operations were used in the study to evaluate the dust suppression effect under each treatment plan.

[0044] The processing used includes:

[0045] • Water-used in many mineral processing operations to control dust formation in retention dams and / or tailings ponds.

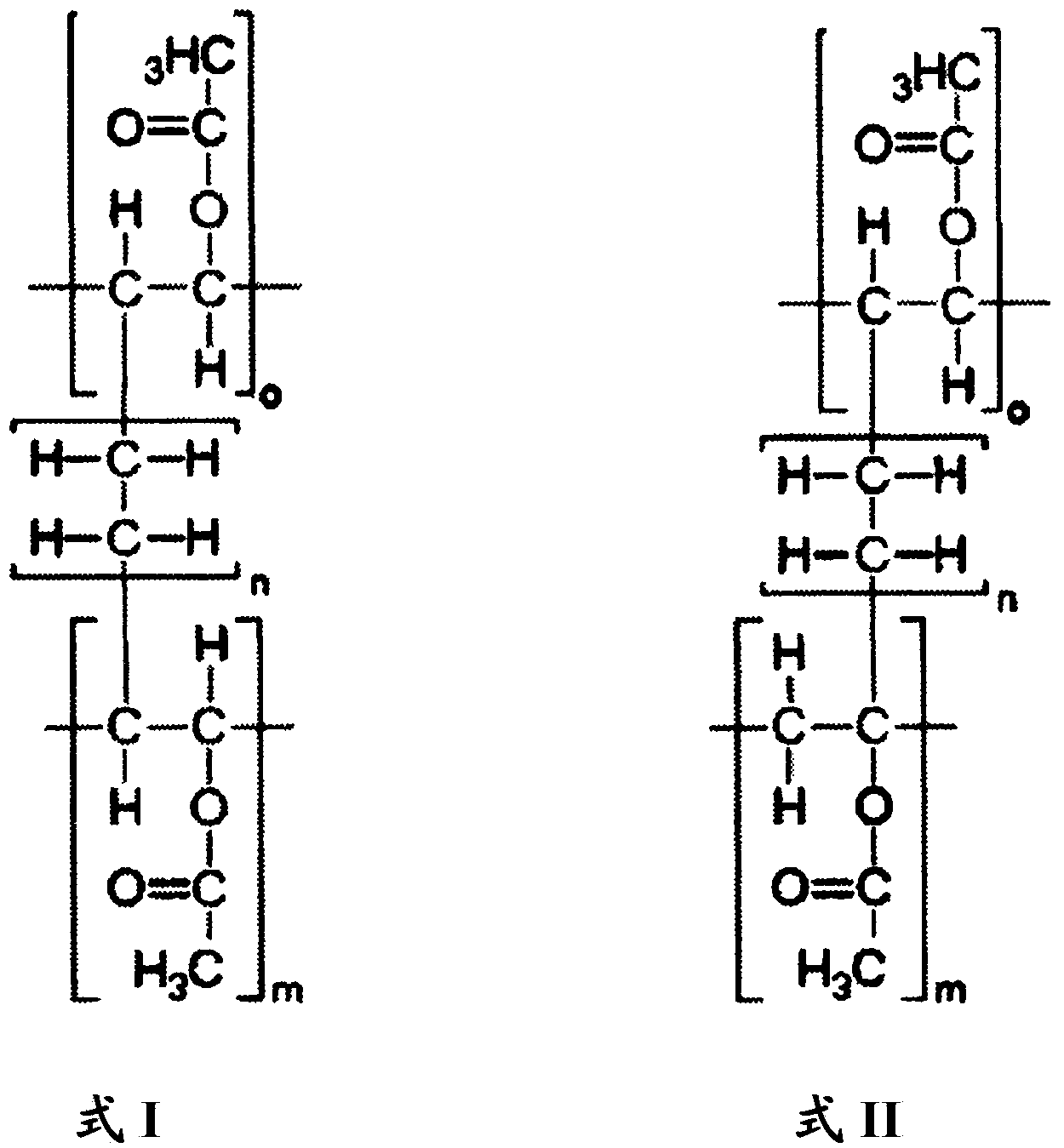

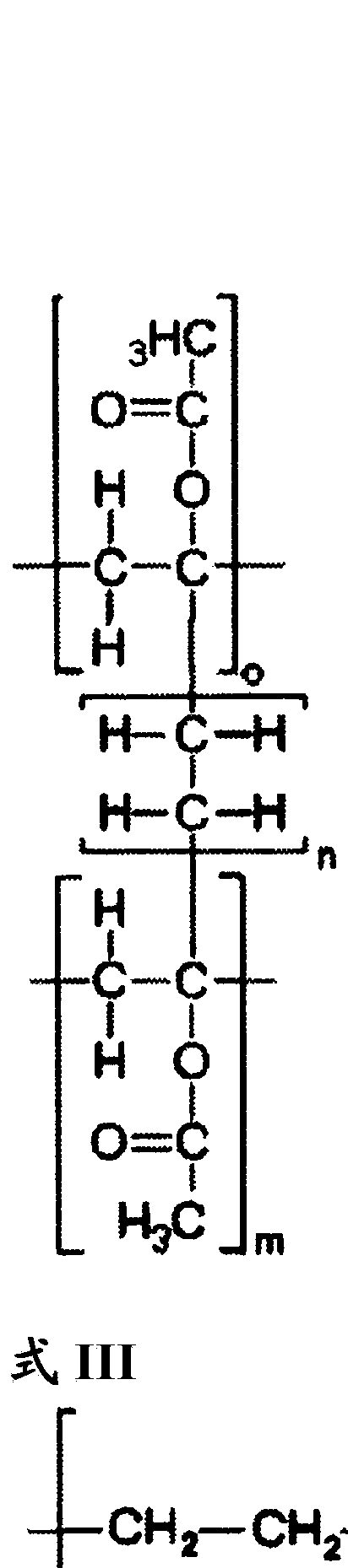

[0046] · Comparative Example #1: A commercially available dust control product containing a styrene-acrylate copolymer.

[0047] · Comparative Example #2: A commercially available dust control product containing a concentrated glycerin aqueous solution.

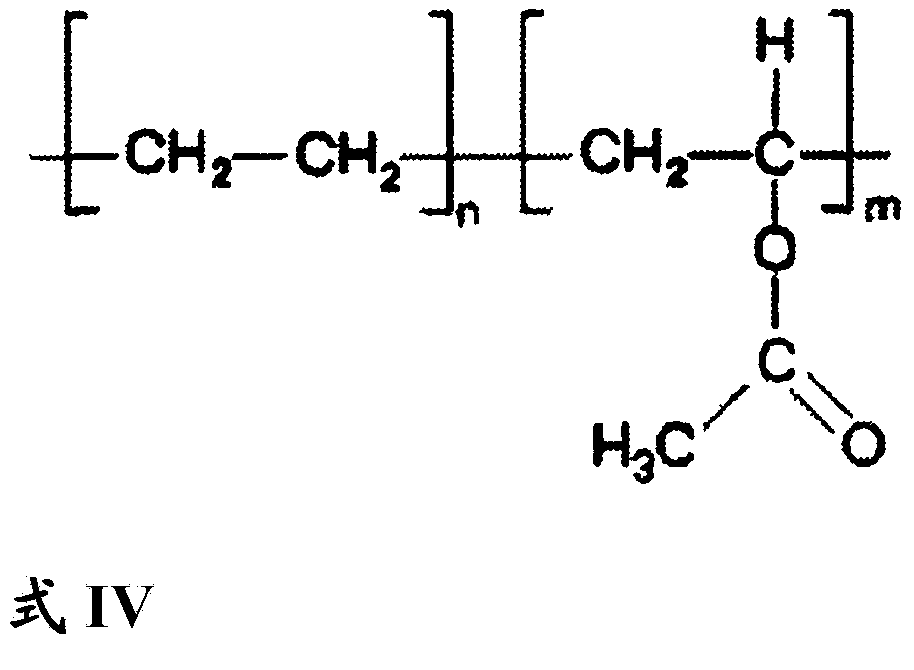

[0048] · Product A-a 50:50 mixture containing VAE copolymer and crude glycerin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com