Workshop-level manufacturing capability oriented dynamic comprehensive assessment method

A manufacturing capability and comprehensive evaluation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of incomplete, inconsistent, and incomplete evaluation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

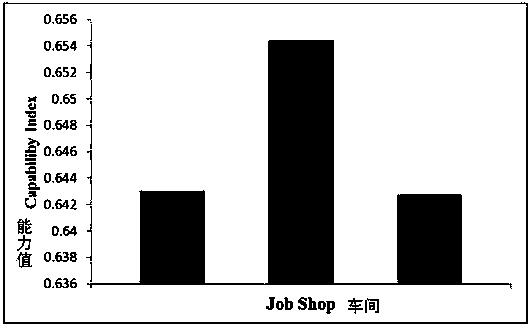

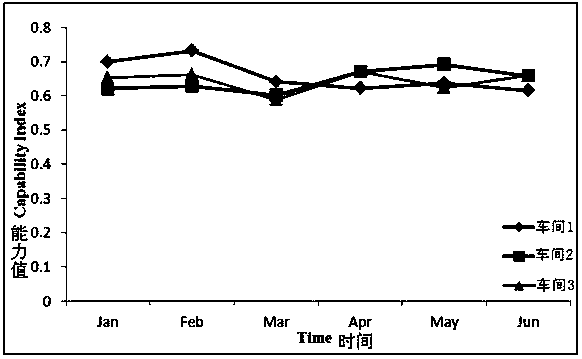

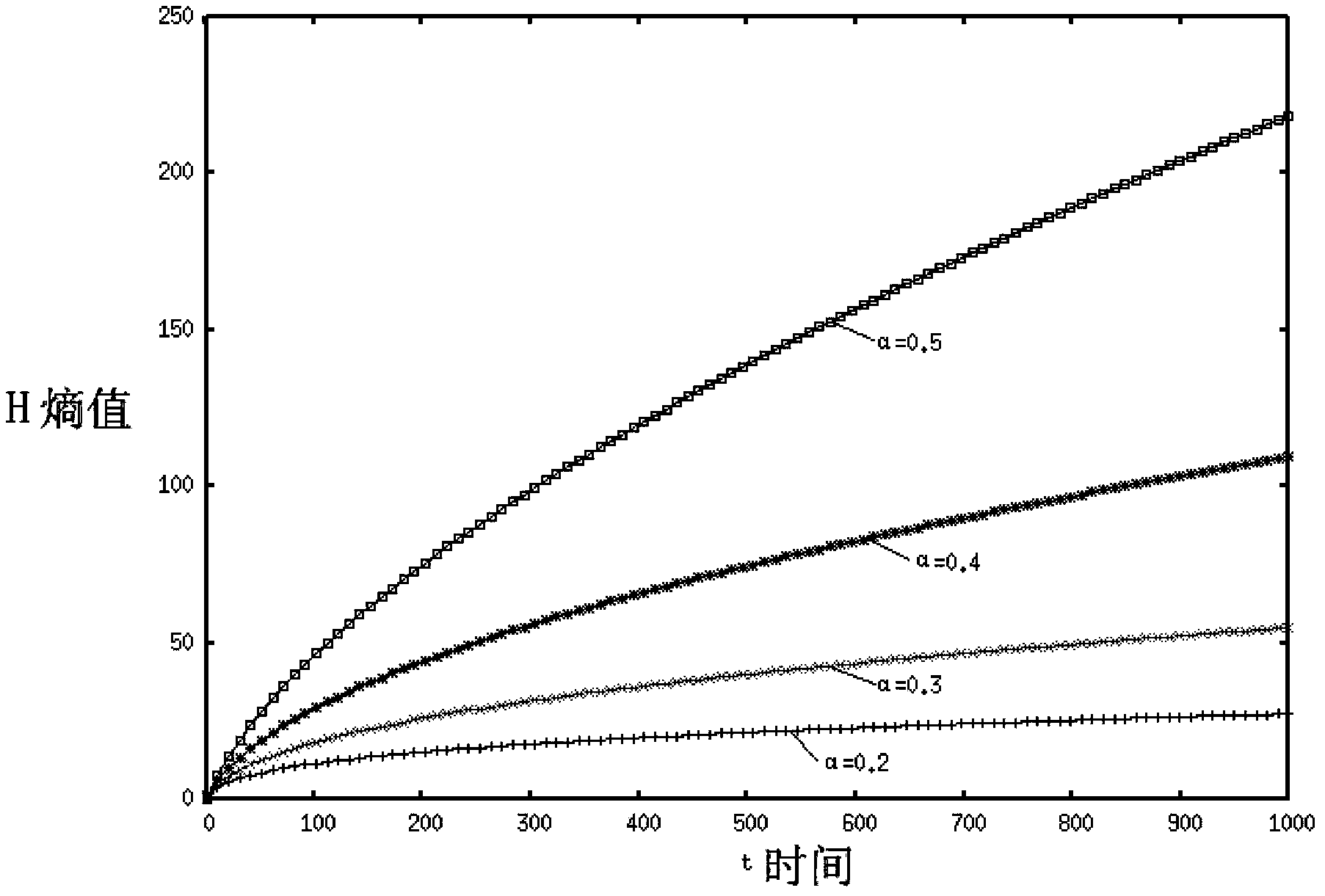

[0048] The dynamic comprehensive evaluation method for workshop-level manufacturing capability designed by the present invention first summarizes and analyzes the constituent elements of workshop-level manufacturing capability, establishes an index system for dynamic comprehensive evaluation of workshop-level manufacturing capability, and then establishes a mathematical model for dynamic evaluation of workshop-level manufacturing capability. Finally, according to the mathematical model, the combination of entropy time weighting and analytic hierarchy process is used to evaluate the manufacturing capability.

[0049] In general the present invention comprises the steps:

[0050] The first step: determine the time weight of the workshop manufacturing data and the weight constraints of different evaluation indicators;

[0051] The second step: setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com