Sensor fixing test rack for uniaxial compression sound emission test of coal petrography and application method of same

An acoustic emission sensor and uniaxial compression technology, which is applied in the direction of material analysis using acoustic emission technology, material analysis using sound wave/ultrasonic wave/infrasonic wave, instruments, etc. Inaccurate position fixation, increased sample loss and test time-consuming problems, to achieve the effect of improving test efficiency and success rate, reducing test time-consuming, and ensuring repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

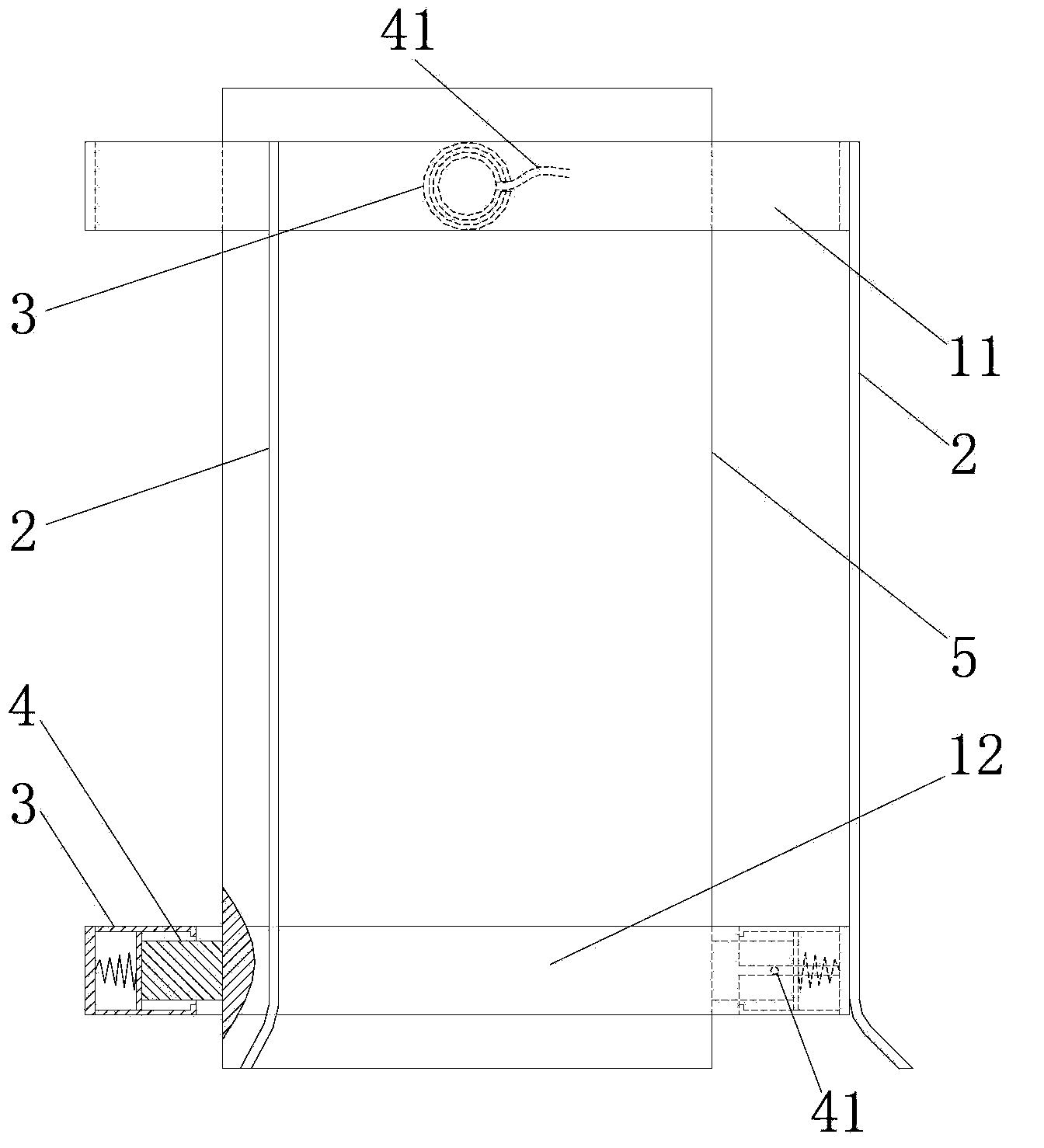

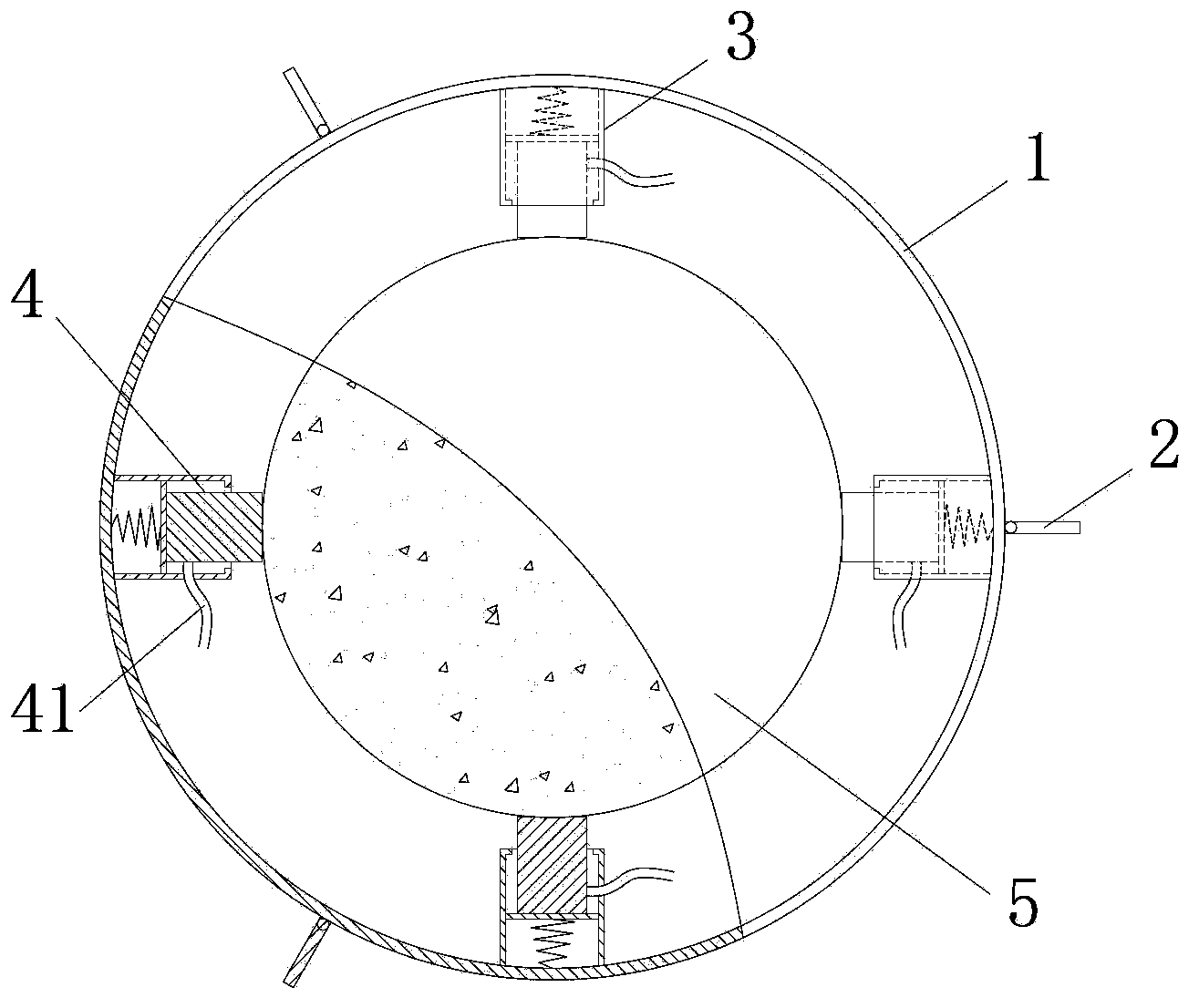

[0022] Such as figure 1 , figure 2 Shown, the round frame 1 of the sensor fixing test stand of the present invention is a cylindrical shell member, and it comprises an upper round frame 11 and a lower round frame 12, and the upper round frame 11 and the lower round frame 12 are passed through three evenly distributed tripods 2 are welded together to jointly play the role of fixing the spatial position of the abutting device 3. Two clinging devices 3 are respectively welded on the upper round frame 11 and the lower round frame 12. The said clinging devices 3 are cylindrical shells with the same shape and size, and their axes are aligned with the center line of the round frame 1. . The two close-fitting devices 3 on the same round frame are distributed symmetrically at intervals of 180 degrees, and the close-fitting devices 3 on the upper round frame 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com