Natural gas compressor piston rod runout measurement device

A technology for measuring devices and compressors, which is applied in the direction of measuring devices and instruments, can solve the problems of unfavorable scientific management of compressors, disadvantages, and little reference significance for compressor performance changes, and achieve simple structure, convenient installation, and easy processing and manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

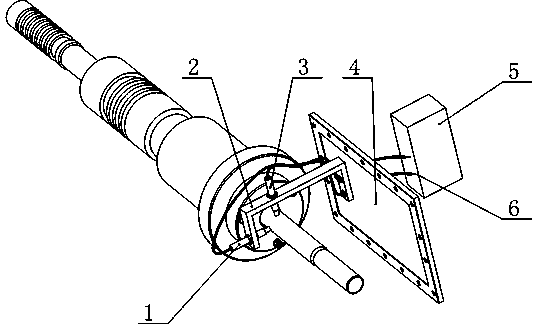

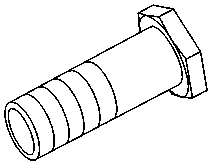

[0025] Such as figure 1 , figure 2 with image 3 As shown, the natural gas compressor piston rod runout measuring device includes a compressor control system 5, and also includes a horizontal measuring instrument 1, a measuring mounting frame 2, a vertical measuring instrument 3, two data transmission cables 6 and a middle body cover 4. The measuring mounting frame 2 is fixedly connected to the middle body cover 4, the level measuring instrument 1 and the vertical measuring instrument 3 are both fixedly connected to the measuring mounting frame 2, and the horizontal measuring instrument 1 is axially located in the horizontal direction, The straight measuring instrument 3 is axially located in the vertical direction, and the horizontal measuring instrument 1 and the vertical measuring instrument 3 are respectively connected to the compressor control system 5 through a data transmission cable 6.

[0026] Compressor control system 5 can use GE9070PLC compressor instruments and equi...

Embodiment 2

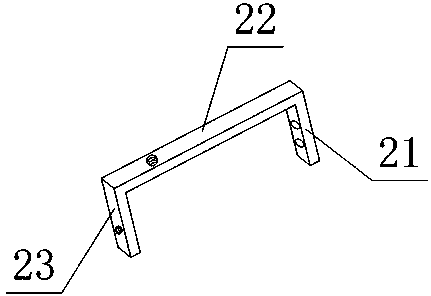

[0028] This embodiment is further limited on the basis of embodiment 1, such as figure 1 , figure 2 with image 3 As shown, the measurement mounting frame 2 includes a right wing plate 21, a web 22, and a left wing plate 23. The left wing plate 23 and the right wing plate 21 are respectively fixedly connected to one end of the web 22, and the left wing plate 23 and the right wing plate 21 are connected to each other. The included angles of the web 22 are all 90°, the horizontal measuring instrument 1 is fixedly connected to the left wing plate 23, and the vertical measuring instrument 3 is fixedly connected to the web 22.

[0029] This structure is simple in structure and easy to manufacture. In this structure, the 90° included angle between the left wing plate 23 and the web 22 makes the installation angle requirements of the horizontal measuring instrument 1 and the vertical measuring instrument 3 easy to achieve.

[0030] Both the web 22 and the left wing plate 23 are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com