Material coating automatic transporting line lifting appliance idle station returning technological method

An automatic conveying and empty station technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of large investment in infrastructure equipment, large occupation of workshop space, and small investment, so as to save infrastructure costs and return costs The effect of reducing, large economic benefit and social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

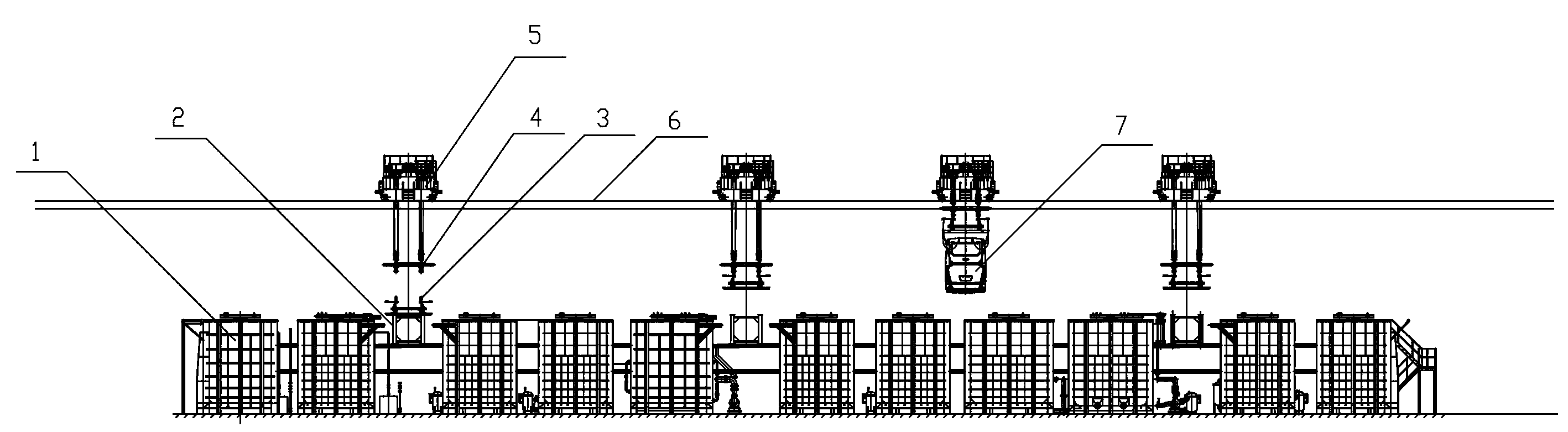

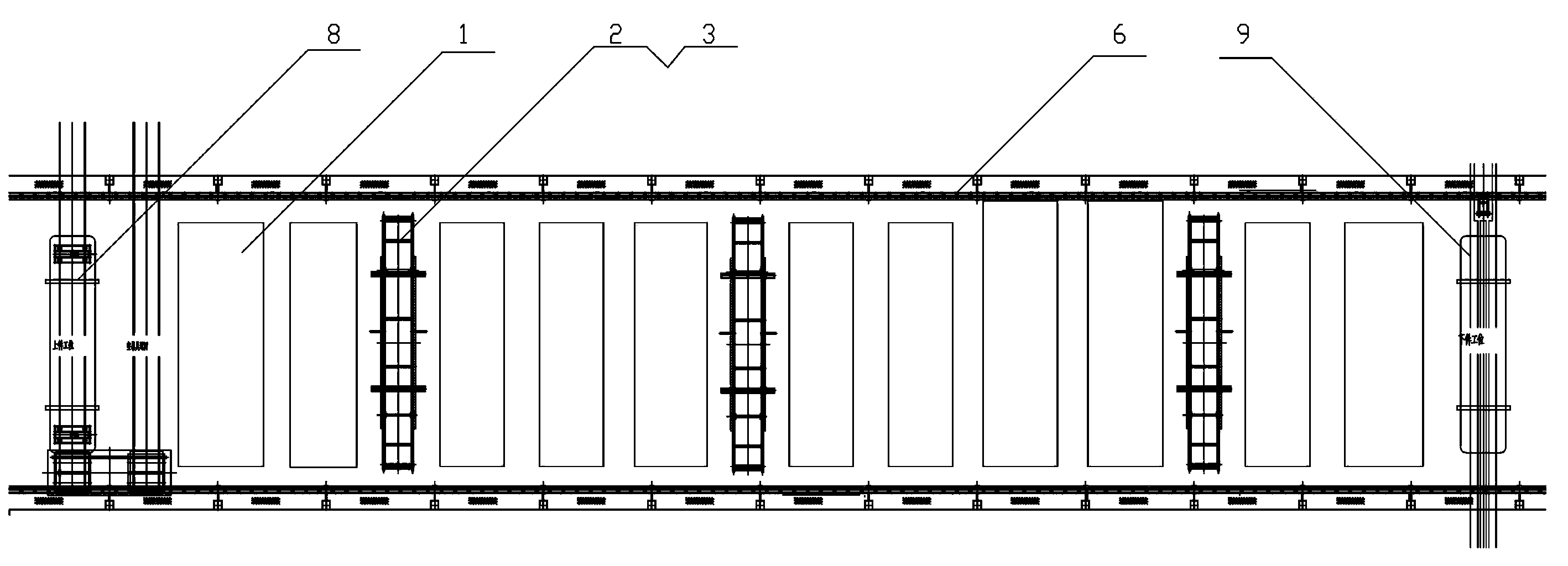

[0009] see figure 1 , 2 , the process method of material coating automatic conveying line hanger empty station return of the present invention is arranged with a row of eleven treatment process tanks 1, and is divided into four groups, wherein the first group includes 2 treatment process tanks, the second The group includes 3 treatment process tanks, the third group includes 4 treatment process tanks, and the fourth group includes 2 treatment process tanks; the top of the treatment process tank 1 is provided with a driving track 6, and the driving track 6 corresponds to each The group processing tank 1 is equipped with a program-controlled crane 5, each program-controlled crane 5 is equipped with a gripper 4, and the outer end of the first processing tank is provided with a loading station 8, and the first program-controlled crane 5 uses a grabber 4 Grab the sling, use the sling to lift the workpiece 7 to be processed on the loading station 8 to the first processing tank 1, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com