Electromechanical converter system for electric vehicles

A conversion system and electric vehicle technology, applied in the direction of motor vehicles, electromechanical devices, electric components, etc., can solve maintenance costs and other problems, and achieve the effect of simple structure and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

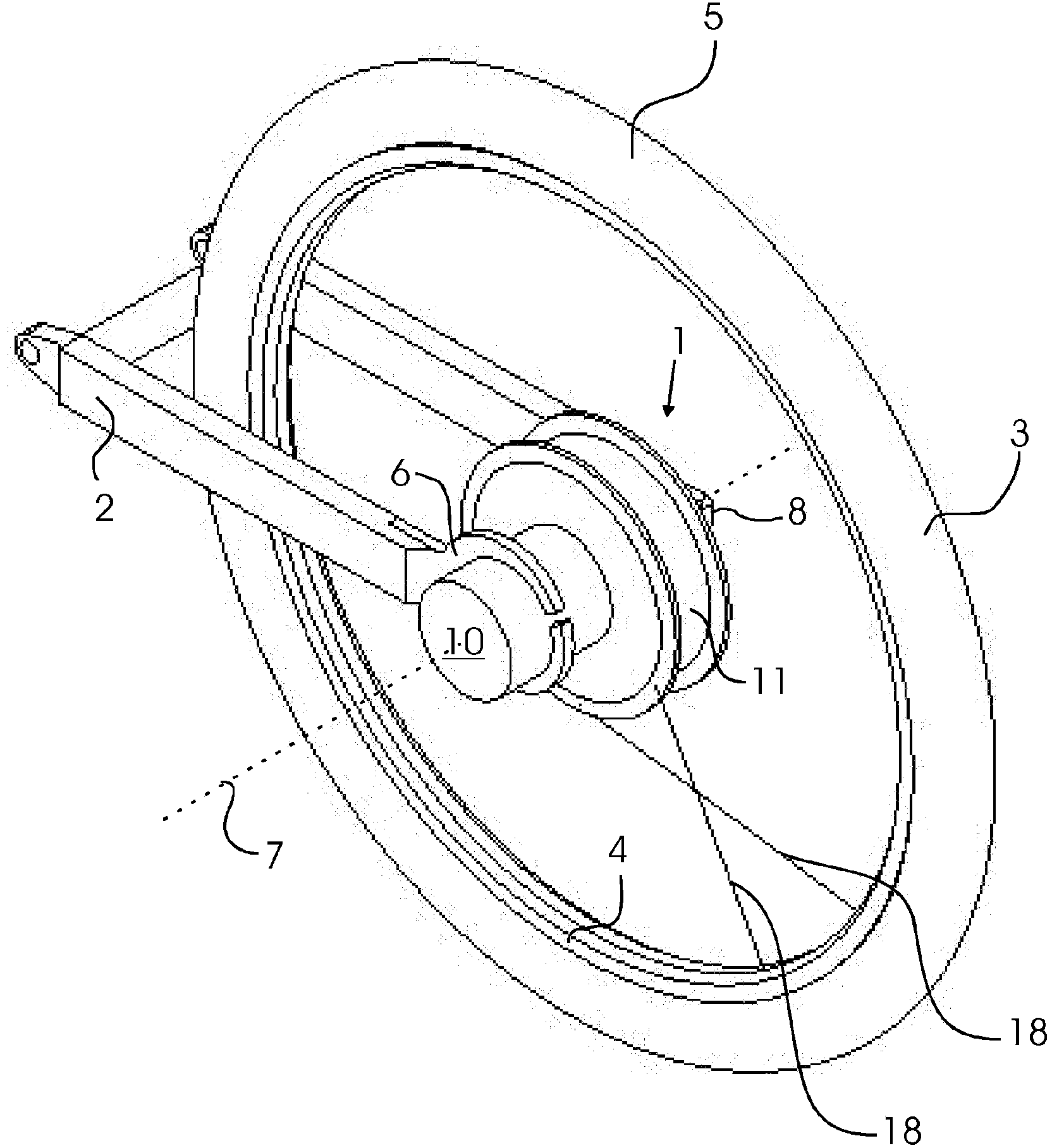

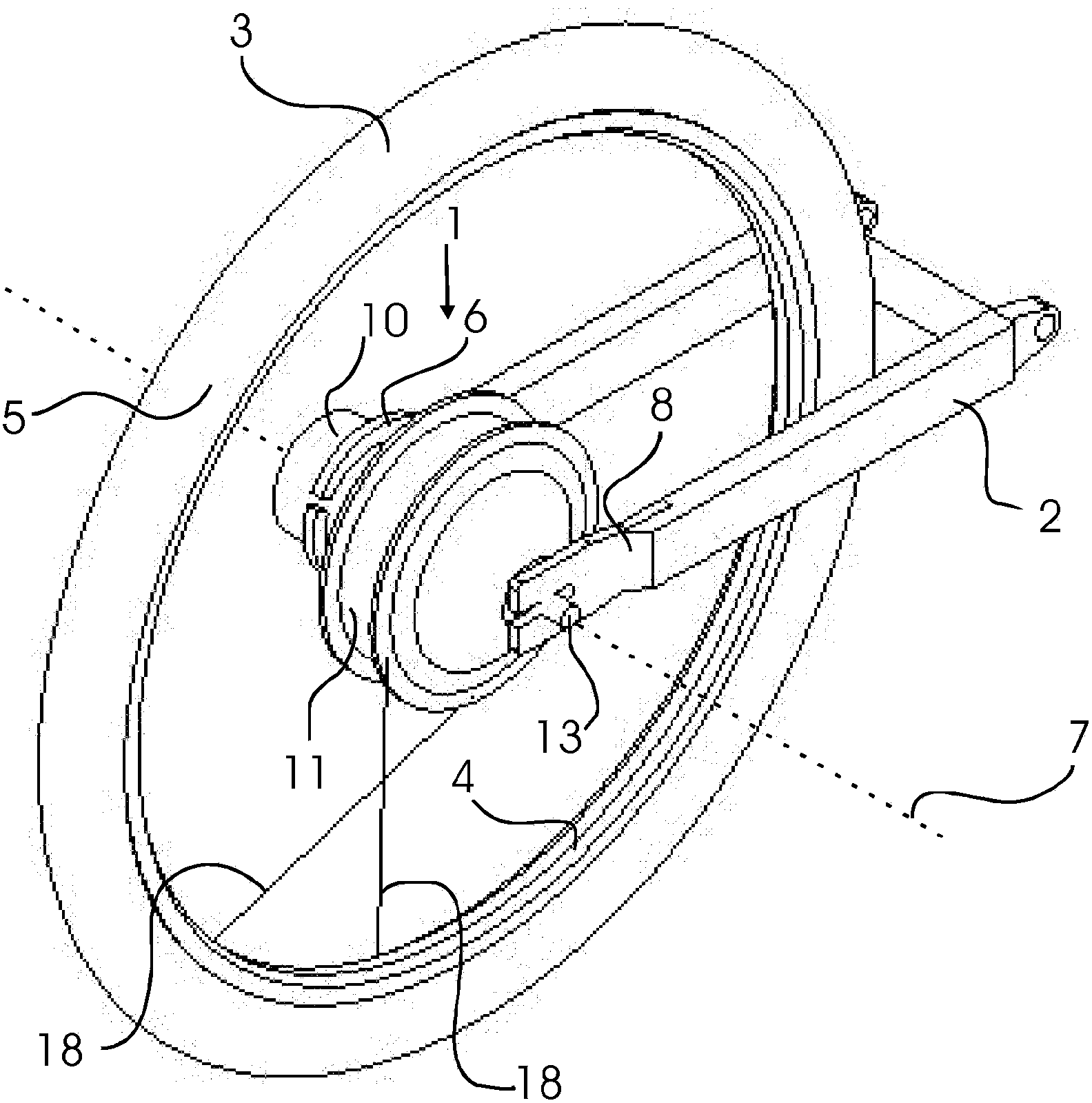

[0088] Figure 1a with 1b A perspective view of a first embodiment of a conversion system 1 according to the invention is shown. The conversion system 1 is shown in the figure in the position of use on the rear wheel arrangement of an electric vehicle, here an electric moped. The electric vehicle includes a frame (not shown) on which a rear wheel balance bar 2 is fixed. As shown, the rear balance bar 2 is configured to be screwable to the frame in order to allow simple installation and removal of the device. Furthermore, the wheel arrangement has a running wheel 3 , which now has a rim and a corresponding inner tube 5 .

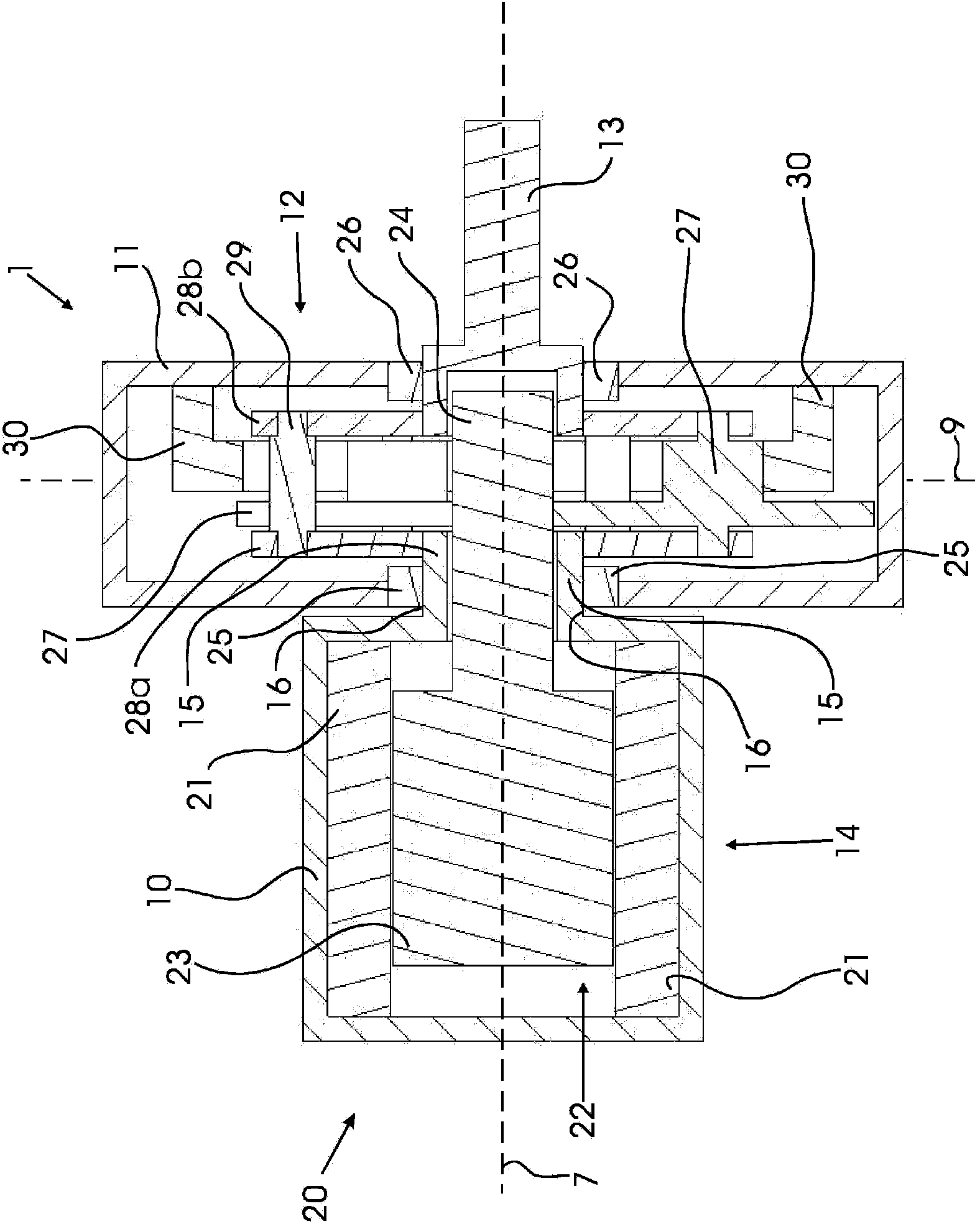

[0089] as can from Figure 1a with Figure 1b As can be seen in the illustration, the conversion system 1 has a support housing 10 which is connected to the frame of the electric vehicle via the ring-shaped parking end 6 of the rear wheel balancer 2 . The carrier housing 10 is cylindrical and is oriented coaxially to the drive axis 7 . Next to the carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com